Discover the Benefits of Flexible Printed Circuit Boards

By:Admin

One company at the forefront of this trend is {Company Name}, a leading manufacturer of high-quality FPCBs. With a strong focus on innovation and customer satisfaction, {Company Name} has established itself as a trusted partner for companies looking for advanced FPCB solutions.

{Company Name} was founded in {year}, with a vision to revolutionize the FPCB industry through cutting-edge technology and a customer-centric approach. Over the years, the company has invested heavily in research and development, leading to the creation of state-of-the-art manufacturing processes and a diverse range of FPCB products. {Company Name} has also built a strong global presence, with a network of partners and customers across various industries.

One of the key factors that set {Company Name} apart from its competitors is its commitment to quality. The company follows stringent quality control measures at every stage of the manufacturing process, ensuring that its FPCBs meet the highest industry standards. This focus on quality has earned {Company Name} a reputation for reliability and performance, making it the preferred choice for many leading electronics manufacturers.

In addition to its commitment to quality, {Company Name} is also known for its ability to offer customized FPCB solutions to meet specific customer requirements. The company's team of experienced engineers works closely with clients to understand their needs and develop tailored FPCB designs that are both functional and cost-effective. This flexibility has made {Company Name} a trusted partner for companies looking to innovate and differentiate their products in the market.

{Company Name} also prides itself on its commitment to environmental sustainability. The company has implemented eco-friendly practices throughout its manufacturing facilities, minimizing waste and energy consumption. By prioritizing sustainability, {Company Name} aims to contribute to a greener and more sustainable future for the electronics industry.

Looking ahead, {Company Name} is poised to capitalize on the growing demand for FPCBs, driven by the proliferation of IoT devices, the expansion of the automotive electronics market, and the increasing adoption of wearable technology. The company's focus on innovation, quality, and customer satisfaction positions it well to continue its growth and expansion in the highly competitive FPCB industry.

In conclusion, FPCBs have become indispensable in the modern electronics industry, and companies like {Company Name} are playing a crucial role in shaping the future of this market. With its focus on innovation, quality, and customer-centric solutions, {Company Name} has established itself as a leader in the FPCB industry and is well-positioned for continued success in the years to come.

Company News & Blog

Next-Generation Gaming Device PCB Revealed in Latest News

[Publication Name]: PlayStation Gaming Device PCB (Brand Name Removed) Revolutionizes Gaming Experience[City, Date] - The gaming industry has been revolutionized with the introduction of the latest PlayStation Gaming Device PCB, a game-changer developed by a leading technology company. This cutting-edge device has taken gaming to new heights, providing an immersive and exhilarating experience for avid gamers worldwide.With its sleek design and powerful performance, the PlayStation Gaming Device PCB sets a new standard for gaming consoles. Boasting state-of-the-art technology, it offers enhanced graphics, faster loading times, and improved gameplay, making it an irresistible choice for both casual and professional gamers.The company behind this breakthrough innovation, [Company Name], has been at the forefront of technology development for decades. With a strong emphasis on research and development, they have consistently pushed the boundaries of what is possible in the gaming industry. The PlayStation Gaming Device PCB is the culmination of their relentless commitment to excellence and innovation.At the core of the PlayStation Gaming Device PCB lies a robust printed circuit board (PCB) that serves as the central nervous system of the console. This high-performance PCB is responsible for coordinating all the essential components, ensuring seamless gameplay and delivering an unmatched gaming experience. Through strategic collaborations with leading manufacturers, [Company Name] has perfected this crucial component, ensuring reliability and durability.One of the standout features of the PlayStation Gaming Device PCB is its advanced graphics processing unit (GPU). This powerful GPU is specifically designed to handle complex graphics rendering, delivering stunning visuals that bring games to life. Whether it's exploring vast virtual worlds or engaging in fast-paced action sequences, gamers will be captivated by the lifelike graphics this device delivers.Additionally, the PlayStation Gaming Device PCB showcases a lightning-fast solid-state drive (SSD), significantly reducing load times. This technological advancement enables gamers to jump into their favorite games within seconds, eliminating frustrating waiting times. With quicker load times, players can spend more time immersed in gameplay, enhancing the overall experience.Furthermore, the PlayStation Gaming Device PCB boasts a robust cooling system engineered to prevent overheating, even during extended gaming sessions. By effectively dissipating heat, this device ensures peak performance, allowing gamers to play for hours on end without interruptions. This attention to detail is a testament to [Company Name]'s dedication to creating a flawless gaming device.To enhance the accessibility of the PlayStation Gaming Device PCB, the company has incorporated a user-friendly interface that makes navigation seamless for both novice and experienced gamers. With intuitive controls and an array of connectivity options, this device offers versatility and convenience, ultimately providing gamers with complete control over their gaming experience.Commenting on the release of the PlayStation Gaming Device PCB, [Company Name]'s CEO expressed excitement about the transformative impact it would have on the gaming industry, stating, "We believe in pushing the boundaries of technology to deliver memorable and immersive gaming experiences. The PlayStation Gaming Device PCB represents our commitment to innovation and our passion for creating devices that truly enhance users' lives."As the gaming industry continues to evolve, the PlayStation Gaming Device PCB marks a significant milestone. Combining the latest technological advancements with the company's expertise, this device is set to revolutionize the way we play games. With its impressive features and relentless commitment to excellence, the future of gaming has never been brighter.In an increasingly competitive market, the PlayStation Gaming Device PCB positions [Company Name] as a leader, setting a new standard for gaming consoles. As gamers eagerly await the release of this groundbreaking device, the anticipation and excitement surrounding its arrival continue to grow. Indeed, the PlayStation Gaming Device PCB is poised to establish itself as an unrivaled force in the gaming industry.

High quality 16 layer PCB - Everything You Need to Know

16 Layer PCB Technology: Revolutionizing Electronics ManufacturingIn today's fast-paced and ever-evolving digital world, the demand for smaller, faster, and more efficient electronic devices is at an all-time high. As a result, innovation in printed circuit board (PCB) technology has become increasingly important. One company at the forefront of this revolution is [Company Name], a leading provider of cutting-edge 16 layer PCB technology.With over [Number] years of experience in the industry, [Company Name] has established itself as a trusted and reliable partner for manufacturers of a wide range of electronic devices, including smartphones, tablets, laptops, and industrial equipment. Their advanced 16 layer PCB technology has set a new standard for performance, reliability, and miniaturization in the electronics manufacturing industry.What sets [Company Name]'s 16 layer PCB technology apart is its ability to accommodate a larger number of components and interconnections in a much smaller footprint compared to traditional PCBs. This breakthrough has enabled electronic device manufacturers to design and produce smaller, more powerful, and more energy-efficient products than ever before.The key to [Company Name]'s 16 layer PCB technology lies in their state-of-the-art manufacturing processes and cutting-edge materials. By leveraging the latest advancements in PCB design and fabrication, they are able to produce high-density interconnect (HDI) boards with incredible precision and reliability. This level of sophistication allows for a significant increase in the density of electronic components on the board, while maintaining signal integrity and minimizing electromagnetic interference.In addition to their technical prowess, [Company Name] is also committed to providing exceptional customer support and collaboration throughout the entire design and manufacturing process. Their team of experienced engineers and technicians work closely with their clients to understand their specific requirements and constraints, ensuring that the final product meets or exceeds their expectations.The impact of [Company Name]'s 16 layer PCB technology is far-reaching, extending beyond the realm of consumer electronics. Industries such as aerospace, automotive, medical, and telecommunications have all benefited from the increased performance and miniaturization made possible by this revolutionary technology. This has opened up new possibilities for innovation and advancement in these sectors, ultimately leading to better and more efficient products for consumers and businesses alike.Looking ahead, [Company Name] is continuing to push the boundaries of PCB technology with ongoing research and development initiatives. They are actively exploring new materials, processes, and design techniques to further enhance the performance and capabilities of their 16 layer PCB technology. With a strong focus on innovation and customer satisfaction, [Company Name] is well-positioned to remain a leader in the electronics manufacturing industry for years to come.In conclusion, [Company Name]'s 16 layer PCB technology represents a significant leap forward in the evolution of electronic devices. By enabling smaller, more powerful, and more energy-efficient products, this groundbreaking technology is driving innovation and shaping the future of electronics manufacturing. With their expertise, dedication, and commitment to excellence, [Company Name] is poised to continue making a lasting impact on the industry and the world at large.

Discover the Advantages of 8 Layer PCBs: A Comprehensive Guide

Title: Leading PCB Manufacturer Introduces Cutting-edge 8 Layer PCB for Enhanced PerformanceIntroduction:In a bid to cater to the growing demands of various industries, a prominent PCB manufacturer has recently unveiled their latest innovation - an advanced 8 layer PCB. Leveraging their expertise in circuit board manufacturing, this breakthrough technology is set to revolutionize electronic devices, promising superior performance and efficiency. With the ability to accommodate complex circuitry while ensuring optimal signal integrity, this new product is poised to become a game-changer in the industry.Body:1. Understanding the Need for 8 Layer PCBs:As electronic devices continue to evolve, the demand for increased processing power, miniaturization, and improved functionality has grown exponentially. Manufacturers require more sophisticated circuitry, necessitating greater design flexibility and enhanced signal transmission capabilities. Here, 8 layer PCBs offer a dynamic solution by providing additional layers and routing options, effectively reducing signal interference and promoting seamless performance.2. Enhanced Signal Integrity and Reduced Interference:The key feature of 8 layer PCBs lies in its ability to support through-hole technology, surface mount devices, and high power applications while simultaneously mitigating electromagnetic interference (EMI) and crosstalk. The additional layers facilitate greater flexibility in designing signal paths, ensuring optimum performance across complex circuitry. Electronic components can now be placed closer together, resulting in shorter interconnections, reduced noise, and improved overall signal integrity.3. Improved Thermal Management:Heat dissipation is a critical factor in maintaining the long-term reliability and performance of electronic devices. The additional layers in 8 layer PCBs facilitate effective thermal management through the incorporation of copper planes that act as heat sinks. These thermal planes dissipate excess heat, thereby safeguarding the integrity of sensitive components and extending their operational life.4. Multi-functionality and Versatility:Manufacturers across various industries, such as automotive, aerospace, telecommunications, and healthcare, are increasingly relying on electronic devices that demand intricate circuit designs. 8 layer PCBs provide ample space for layer-by-layer insulation, ensuring that different circuit elements do not interfere with each other. This enables the smooth integration of diverse components, resulting in compact yet efficient electronic products.5. The Advantages of Working with Manufacturer XYZ:Manufacturer XYZ, a renowned PCB manufacturer, has consistently been at the forefront of technological advancements in the industry. With a strong commitment to innovation and quality, they have gained a reputation for delivering cost-effective solutions tailored to meet specific customer requirements. Their cutting-edge manufacturing facilities, coupled with a highly skilled workforce, ensure the production of high-performance 8 layer PCBs adhering to international standards.6. Capitalizing on Research and Development:Manufacturer XYZ continuously invests in research and development to stay ahead of market demands. With a comprehensive understanding of evolving industry requirements, they have crafted the 8 layer PCB to provide optimal signal integrity, reduced interference, and improved thermal management. By capitalizing on their technical expertise, this innovative offering from Manufacturer XYZ is set to meet the growing needs of technology-driven sectors.7. Revolutionizing the Industry:The introduction of 8 layer PCBs by Manufacturer XYZ marks a significant milestone in PCB manufacturing. With this advanced technology, electronic devices can achieve unprecedented performance levels, thereby enhancing user experience and pushing the boundaries of innovation. As industries embrace ever-evolving technology, the introduction of these 8 layer PCBs is expected to catalyze progress and contribute to the exponential growth of the sector.Conclusion:Manufacturer XYZ's introduction of the cutting-edge 8 layer PCB serves as a testament to their commitment to delivering superior solutions to their customers. By addressing the challenges faced by manufacturers in developing complex circuitry, this technology is poised to revolutionize the industry. The advantages of enhanced signal integrity, reduced interference, improved thermal management, and overall versatility make 8 layer PCBs an indispensable component in the design and manufacturing of high-performance electronic devices. With their extensive experience and dedication to advancing technology, Manufacturer XYZ is likely to maintain its position as a market leader in the PCB manufacturing domain.

How Circuit Boards are Manufactured and its Uses

Smt Circuit Board Company Introduces Cutting-Edge TechnologySmt Circuit Board, a leading manufacturer of high-quality printed circuit boards, is revolutionizing the industry with the introduction of their state-of-the-art production technology. The company, with its headquarters in (location), has been at the forefront of innovation for over a decade, and their latest technological advancement is set to further cement their position as a pioneer in the field.The new technology, which the company has developed in-house, promises to significantly enhance the efficiency and precision of the manufacturing process. Through the integration of advanced robotics and automated systems, Smt Circuit Board has been able to achieve unprecedented levels of accuracy and consistency in the production of their circuit boards. This breakthrough will not only enable the company to meet the growing demand for their products but also to exceed the expectations of their customers in terms of quality and reliability.In addition to improving the manufacturing process, Smt Circuit Board's new technology also has the potential to reduce production costs, making their products more competitive in the market. By streamlining operations and minimizing the margin for error, the company anticipates being able to offer their cutting-edge circuit boards at more competitive prices, thereby further increasing their appeal to existing and prospective customers."We are thrilled to announce the launch of our latest technological innovation," said the CEO of Smt Circuit Board. "We have always been committed to pushing the boundaries of what is possible in the world of printed circuit board manufacturing, and this new development is a testament to that commitment. We believe that this technology will not only benefit our company but also the entire industry as a whole, by setting a new standard for excellence and efficiency."The company's dedication to innovation and excellence is further reflected in their commitment to sustainability. Smt Circuit Board has made substantial investments in environmentally friendly production methods, and their new technology is no exception. By optimizing resource utilization and reducing waste, the company seeks to minimize their environmental footprint and contribute to a more sustainable future for the industry.Smt Circuit Board's cutting-edge technology has already garnered significant attention from industry insiders and experts, with many hailing it as a game-changer for the printed circuit board manufacturing sector. The company has already begun the process of integrating the new technology into their production facilities, and they expect to see tangible results in the near future."We are confident that this technology will position us as a leader in the industry and enable us to continue delivering superior products and services to our customers," said the CEO. "We are excited about the possibilities that this innovation opens up for us, and we look forward to the positive impact it will have on our business and the industry as a whole."As Smt Circuit Board prepares to roll out their groundbreaking new technology, the company is poised to reaffirm its position as a frontrunner in the printed circuit board manufacturing sector. With a track record of innovation, excellence, and customer satisfaction, Smt Circuit Board is set to continue leading the way in the industry for years to come.

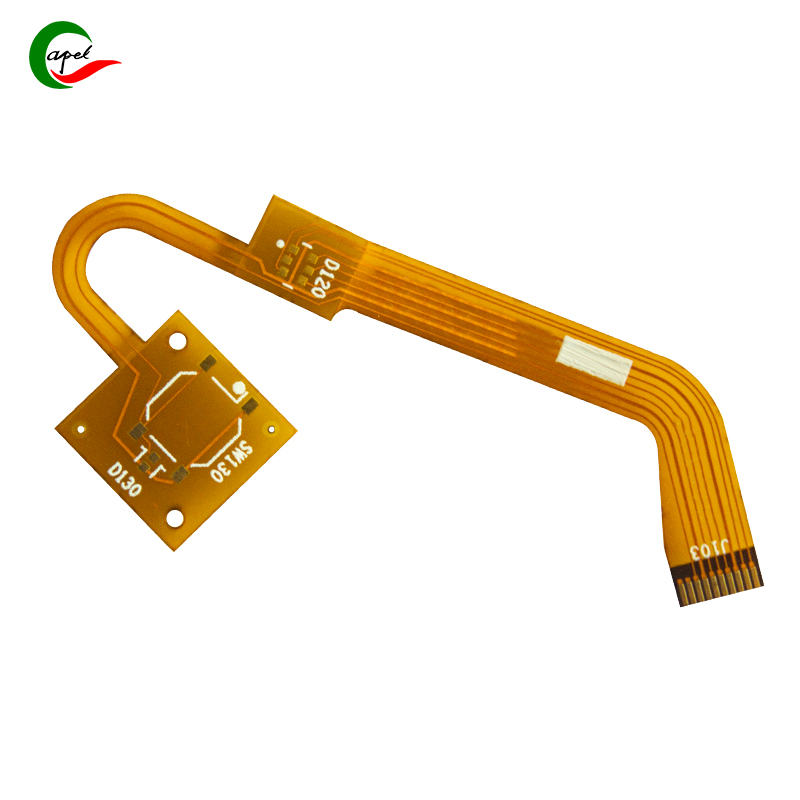

High-Quality Semi-Rigid Flex PCB for Your Electronic Needs

Semi Rigid Flex PCB is a type of flexible printed circuit board (PCB) that offers a unique combination of flexibility and rigidity, making it suitable for a wide range of applications. This innovative technology is now being offered by {Company Name}, a leading provider of high-quality PCB solutions.{Company Name} has been at the forefront of PCB manufacturing and assembly for over a decade. With a strong focus on innovation and quality, the company has built a reputation for delivering cutting-edge PCB products to a diverse range of industries. With the introduction of Semi Rigid Flex PCB, {Company Name} is poised to further strengthen its position in the market as a trusted PCB supplier.Semi Rigid Flex PCB is designed to provide a flexible solution for applications that require a combination of flexibility and rigidity. This makes it ideal for use in products where space is limited, and where traditional rigid PCBs may not be suitable. The semi-rigid nature of these PCBs allows for bending and folding, while still maintaining the necessary rigidity for component mounting and assembly.{Company Name} understands the unique demands of modern technology, and the need for advanced PCB solutions to meet these demands. With the introduction of Semi Rigid Flex PCB, the company aims to address the evolving needs of its customers and provide them with a versatile and reliable PCB solution that can be tailored to their specific requirements.The use of Semi Rigid Flex PCB offers numerous benefits for product designers and manufacturers. The flexibility of these PCBs allows for greater freedom in designing complex and compact electronic products, while their rigidity ensures the reliability and durability of the final product. These PCBs can also be used to minimize the need for connectors and wires, thereby reducing the overall size and weight of the final product.{Company Name} has invested heavily in research and development to offer a range of custom semi-rigid flex PCB solutions that meet the unique requirements of its clients. Whether it is a complex aerospace application or a high-density consumer electronics product, {Company Name} has the expertise and capabilities to deliver custom semi-rigid flex PCBs that meet the highest quality standards.In addition to offering high-quality products, {Company Name} also prides itself on providing exceptional customer service and support. The company's team of experienced engineers and technical experts work closely with customers to understand their specific needs and develop customized solutions that meet their requirements. This level of commitment and dedication has helped {Company Name} build long-lasting relationships with its clients and establish itself as a trusted partner in the PCB industry.{Company Name}'s investment in Semi Rigid Flex PCB technology reflects its ongoing commitment to innovation and excellence. By offering this advanced PCB solution, the company aims to continue providing its customers with cutting-edge products that help them stay ahead in a competitive market. With the flexibility and rigidity offered by Semi Rigid Flex PCB, {Company Name} is well-positioned to meet the evolving needs of its clients and provide them with the high-quality PCB solutions they need to succeed.In conclusion, the introduction of Semi Rigid Flex PCB by {Company Name} represents a significant step forward in the PCB industry. This innovative technology offers a unique combination of flexibility and rigidity, making it suitable for a wide range of applications. With its commitment to quality, innovation, and customer satisfaction, {Company Name} is well-equipped to lead the way in delivering advanced PCB solutions to its clients.

Everything You Need to Know About Flex Circuit Boards

Flex Circuit Board Technology is a leading manufacturer of high-quality flexible circuit boards for a wide range of applications. The company prides itself on its innovative technology, superior quality, and exceptional customer service. With state-of-the-art facilities and a team of experienced professionals, Flex Circuit Board Technology is committed to providing cutting-edge solutions for its customers' needs.Flex Circuit Board Technology offers a variety of flexible circuit board products, including single-sided, double-sided, and multilayer flex circuits. These products are highly versatile and can be used in an array of industries, such as automotive, medical, aerospace, and consumer electronics. The company's flexible circuit boards are known for their reliability, performance, and durability, making them an ideal choice for various demanding applications.In addition to its standard product offerings, Flex Circuit Board Technology also provides custom design and manufacturing services to meet the unique requirements of its customers. Its team of engineers and designers works closely with clients to develop tailored solutions that address specific design challenges and performance criteria. From concept to production, the company's comprehensive design and manufacturing capabilities ensure that its customers receive the highest quality flexible circuit boards that are perfectly suited to their needs.One of the key advantages of Flex Circuit Board Technology's products is their ability to provide space and weight savings in comparison to traditional rigid circuit boards. This feature is particularly beneficial in applications where size and weight constraints are critical, such as portable electronic devices, medical implants, and aerospace components. The company's flexible circuit boards also offer improved electrical performance, higher reliability, and greater flexibility in design, making them an attractive choice for a wide range of applications.Flex Circuit Board Technology is dedicated to staying at the forefront of technological advancements in the flexible circuit board industry. Its research and development team continuously explores new materials, processes, and technologies to enhance the performance and capabilities of its products. By investing in innovation, the company aims to offer its customers the latest advancements in flexible circuit board technology, ensuring that they stay ahead of the competition and meet the evolving demands of their respective markets.In addition to its commitment to innovation, Flex Circuit Board Technology emphasizes the importance of quality and reliability in all aspects of its operations. The company adheres to stringent quality control standards throughout the design and manufacturing process, ensuring that its products consistently meet or exceed industry standards. Its dedication to quality has earned it a strong reputation for delivering reliable and high-performance flexible circuit boards that exceed customer expectations.As part of its customer-centric approach, Flex Circuit Board Technology places a strong emphasis on building and maintaining long-term relationships with its clients. The company works closely with its customers to understand their unique requirements and provide personalized support and guidance throughout the design and manufacturing process. Its collaborative approach and responsive customer service have earned it the trust and loyalty of numerous clients, who rely on its expertise and reliability to meet their flexible circuit board needs.Flex Circuit Board Technology's commitment to excellence, innovation, and customer satisfaction positions it as a trusted leader in the flexible circuit board industry. With its comprehensive product offerings, custom design capabilities, and unwavering dedication to quality, the company continues to be a preferred partner for businesses seeking high-performance flexible circuit board solutions. As the demand for flexible circuit boards continues to grow across various industries, Flex Circuit Board Technology is well-equipped to meet the evolving needs of its customers and maintain its position as a leading provider of flexible circuit board technology.

Top 10 Tips for Multilayer PCB Manufacturing

Multilayer PCB Manufacturing has become an essential part of the modern electronics industry. With the increasing demand for smaller and more complex electronic devices, the need for multilayer PCBs has grown significantly. {} is one of the leading companies in the multilayer PCB manufacturing industry, specializing in high-quality, reliable PCBs for a wide range of applications.With a state-of-the-art manufacturing facility and a team of experienced professionals, {} has been at the forefront of innovation in the field of multilayer PCB manufacturing. The company's commitment to quality and customer satisfaction has earned it a strong reputation in the industry.The process of multilayer PCB manufacturing involves the use of advanced technology and precision engineering. {} has invested heavily in cutting-edge equipment and facilities to ensure that its multilayer PCBs meet the highest quality standards. The company utilizes a variety of materials, including FR-4, Rogers, and Teflon, to manufacture PCBs that are suitable for a wide range of applications.One of the key advantages of multilayer PCBs is their ability to accommodate a large number of components in a small space. This makes them ideal for use in compact electronic devices such as smartphones, tablets, and wearable tech. {} specializes in producing multilayer PCBs with high layer counts, allowing for the creation of complex and sophisticated electronic systems.In addition to standard multilayer PCBs, {} also offers a range of advanced capabilities, including HDI (High Density Interconnect) PCBs and rigid-flex PCBs. These advanced technologies allow for even greater miniaturization and integration of electronic components, making {} a preferred choice for customers who require cutting-edge PCB solutions.As a customer-focused company, {} is committed to providing exceptional service and support to its clients. The company works closely with customers to understand their specific requirements and develop custom solutions that meet their needs. Whether it's a prototype for a new product or a large-scale production run, {} has the expertise and resources to deliver high-quality multilayer PCBs on time and within budget.With a strong emphasis on quality control and reliability, {} ensures that its multilayer PCBs meet the highest industry standards. The company uses rigorous testing and inspection processes to verify the performance and durability of its PCBs, giving customers the confidence that they are receiving top-quality products.In an industry that is constantly evolving, {} is committed to staying ahead of the curve. The company continuously invests in research and development to explore new materials, processes, and technologies that will further enhance its multilayer PCB manufacturing capabilities. By staying at the forefront of innovation, {} can continue to meet the evolving needs of its customers and provide them with the most advanced PCB solutions available.As the demand for smaller, more powerful electronic devices continues to grow, the importance of multilayer PCB manufacturing will only increase. With its dedication to quality, innovation, and customer satisfaction, {} is well-positioned to remain a leader in the multilayer PCB manufacturing industry for many years to come.

Innovative 2 Layer Flexible Printed Circuit for Enhanced Performance

2-Layer Flexible Printed Circuit: The Next Step in Advanced TechnologyIn today's rapidly evolving technological landscape, the demand for flexible and adaptable electronic components is on the rise. As the world moves towards more compact and portable devices, the need for innovative and flexible circuitry has become increasingly essential. In response to this demand, {company name} is proud to announce the development of a 2-layer Flexible Printed Circuit that promises to revolutionize the way electronic devices are designed and manufactured.The 2-layer Flexible Printed Circuit is a breakthrough in the field of electronics, providing a high degree of flexibility and adaptability without compromising on performance and reliability. This new innovation is set to redefine the way electronic devices are built, offering a range of benefits that make it an ideal solution for a wide variety of applications.At the heart of this innovation is {company name}'s commitment to pushing the boundaries of technology and delivering cutting-edge solutions to its customers. With years of experience and expertise in the field of electronics, {company name} has established itself as a leader in providing innovative and high-quality electronic components. The development of the 2-layer Flexible Printed Circuit is a testament to the company's dedication to staying ahead of the curve and meeting the evolving needs of the industry.The 2-layer Flexible Printed Circuit is designed to address the challenges posed by traditional rigid circuitry, offering a flexible and versatile alternative that can be seamlessly integrated into a wide range of electronic devices. Its unique design allows for greater freedom in device design and layout, enabling manufacturers to create products that are more compact, lightweight, and durable. This not only enhances the performance of the devices but also opens up new possibilities for design and innovation.In addition to its flexibility, the 2-layer Flexible Printed Circuit offers excellent electrical performance, ensuring reliable and consistent operation in a variety of conditions. Its advanced design and construction allow for high-speed data transmission, low power consumption, and resistance to environmental factors such as temperature and vibration. This makes it an ideal choice for applications where reliability and performance are paramount, such as in the automotive, aerospace, and medical industries.Furthermore, the 2-layer Flexible Printed Circuit is also cost-effective, offering significant savings in both material and manufacturing costs. Its streamlined production process and reduced material requirements make it a more economical option compared to traditional rigid circuitry, without compromising on quality or performance. This makes it an attractive solution for manufacturers looking to optimize their production processes and bring innovative products to market at a competitive price point.As the demand for flexible and adaptable electronic components continues to grow, {company name} remains at the forefront of innovation, driving advancements in technology that are shaping the future of electronics. With the introduction of the 2-layer Flexible Printed Circuit, the company has once again demonstrated its commitment to delivering solutions that not only meet but exceed the needs of its customers. As the industry continues to evolve, {company name} is dedicated to staying ahead of the curve and providing the technology that will drive the next generation of electronic devices.In conclusion, the development of the 2-layer Flexible Printed Circuit represents a significant leap forward in the field of electronics, offering a flexible and adaptable solution that is set to redefine the way electronic devices are designed and manufactured. With its advanced design, exceptional performance, and cost-effective benefits, this innovation is poised to revolutionize the industry and open up new possibilities for electronic device manufacturers. As {company name} continues to lead the way in technology and innovation, the future looks brighter than ever for the world of electronics.

Guide to Finding the Best Medical Device Printed Circuit Boards

Medical Device PCB, a cutting-edge medical technology company, is revolutionizing the healthcare industry with its innovative printed circuit boards (PCBs) designed specifically for medical devices. The company, founded in 2010, has quickly become a leader in the field of medical device PCB manufacturing, providing high-quality, reliable PCBs that are essential for the functioning of medical devices such as patient monitors, imaging equipment, surgical tools, and much more.Medical Device PCB has a state-of-the-art facility equipped with advanced technology and a team of highly skilled engineers and technicians who are dedicated to delivering the highest quality PCBs to their clients. The company prides itself on its ability to provide customized solutions to meet the unique needs of each customer, ensuring that its PCBs are not only reliable and efficient but also optimized for the specific application they will be used in.One of the key advantages of Medical Device PCB's products is their superior performance and reliability. Medical devices require PCBs that can withstand the rigors of the healthcare environment, including exposure to various chemicals, sterilization processes, and frequent use. The company's PCBs are designed and manufactured to meet these demanding requirements, providing healthcare professionals and patients with the confidence that their medical devices will operate safely and effectively.In addition to performance, Medical Device PCB places a strong emphasis on safety and regulatory compliance. The company is fully committed to ensuring that its PCBs meet the stringent quality and safety standards set forth by regulatory bodies such as the Food and Drug Administration (FDA) in the United States and similar organizations in other countries. This dedication to quality and compliance gives customers peace of mind, knowing that they are receiving PCBs that meet the highest industry standards.Medical Device PCB's products have been widely adopted by leading medical device manufacturers around the world. The company has built a strong reputation for delivering PCBs that not only meet the technical requirements of their clients but also exceed their expectations in terms of quality, reliability, and customer service. This has led to numerous long-term partnerships and repeat business, establishing Medical Device PCB as a trusted and preferred supplier in the medical device industry.In line with its commitment to innovation, Medical Device PCB is continually investing in research and development to stay at the forefront of technological advancements. The company is dedicated to staying ahead of industry trends and leveraging the latest technological breakthroughs to enhance the performance and capabilities of its PCBs. This forward-thinking approach ensures that Medical Device PCB's clients have access to the most advanced and reliable PCB solutions available.Furthermore, Medical Device PCB places a strong emphasis on sustainability and environmental responsibility. The company recognizes the importance of minimizing its environmental impact and operates in accordance with strict environmental standards. This includes responsible waste management, energy-efficient processes, and the use of eco-friendly materials whenever possible. By prioritizing sustainability, Medical Device PCB not only contributes to a healthier planet but also aligns with the values of its environmentally conscious customers.As the demand for advanced medical devices continues to grow, Medical Device PCB is well-positioned to play a significant role in shaping the future of healthcare technology. With its exceptional PCBs, unwavering commitment to quality and safety, and dedication to innovation and sustainability, the company is poised to remain a leader in the medical device industry for years to come.In conclusion, Medical Device PCB's innovative approach to PCB manufacturing, combined with its commitment to excellence and sustainability, has positioned the company as a trusted partner for medical device manufacturers worldwide. With a focus on performance, reliability, safety, and compliance, Medical Device PCB is at the forefront of delivering high-quality PCB solutions that are essential for the advancement of healthcare technology.

Discover Top-Notch PCBs: Unveiling the Key to High-Quality Circuit Boards

Title: Revolutionary High-Quality PCB (Need Remove Brand Name) Poised to Transform the Electronics IndustryIntroduction:In a monumental breakthrough, renowned electronic manufacturing company (need remove brand name) has unveiled its latest innovation - a high-quality Printed Circuit Board (PCB). This cutting-edge technology promises to revolutionize the electronics industry by delivering unmatched performance, reliability, and efficiency. With the introduction of this groundbreaking PCB, (need remove brand name) is set to solidify its position as a global leader in electronic manufacturing.Paragraph 1:The high-quality PCB, developed after years of research and development, boasts unparalleled features and capabilities. Comprising state-of-the-art materials and cutting-edge manufacturing processes, it surpasses traditional PCBs in terms of durability, functionality, and cost-effectiveness. This groundbreaking technology opens up endless possibilities for electronic manufacturers and designers, enabling them to create innovative products that cater to various sectors of the industry.Paragraph 2:One of the key factors that sets the high-quality PCB apart is its exceptional performance, even in the most demanding environments. By leveraging advanced design techniques and quality control measures, (need remove brand name) has successfully engineered a PCB that can withstand extreme temperatures, vibrations, and humidity. This remarkable resilience ensures the longevity and reliability of the electronic devices incorporating these PCBs, thereby minimizing costly maintenance and replacements.Paragraph 3:The high-quality PCB also boasts remarkable power efficiency, making it an invaluable asset for the increasingly energy-conscious electronics industry. By reducing power consumption while simultaneously optimizing performance, (need remove brand name) has taken a massive leap towards enabling greener and more sustainable electronic devices. This advancement aligns perfectly with the global push for eco-friendly solutions in the face of climate change and limited resources.Paragraph 4:The company's commitment to staying at the forefront of emerging technologies is evident in its dedication to robust research and development. (Need remove brand name) continuously invests in cutting-edge facilities and highly skilled teams of engineers and designers to ensure that their PCBs remain at the forefront of technological advancement. This commitment to innovation positions (need remove brand name) as a trusted partner for electronic manufacturers seeking to differentiate themselves in a rapidly evolving market.Paragraph 5:Furthermore, the high-quality PCB provides substantial cost advantages, making it an ideal choice for businesses seeking to enhance their competitive edge. By minimizing assembly failures, improving overall performance, and reducing maintenance costs, companies adopting this groundbreaking technology can achieve significant savings in the long run.Paragraph 6:In terms of market expansion, (need remove brand name) anticipates a substantial surge in demand for its high-quality PCBs across a wide range of industries. Automakers, medical device manufacturers, aerospace companies, and telecommunications giants, among many others, stand to benefit immensely from the unprecedented capabilities offered by (need remove brand name)'s PCBs. With the newfound ability to create more efficient and reliable electronic devices, businesses will be better equipped to meet the evolving needs of their customers.Conclusion:As (need remove brand name) introduces its high-quality PCB to the electronics industry, there is an undeniable sense of excitement and anticipation. This groundbreaking innovation is set to transform the industry by empowering manufacturers and designers to create cutting-edge electronic devices that are durable, efficient, and environmentally friendly. (Need remove brand name)'s commitment to pushing the boundaries of technological advancement and delivering unmatched performance solidifies its position as a global leader in electronic manufacturing.