Essential Guide to Printed Circuit Board Fabrication

By:Admin

{Company name} is a leading provider of PCB fabrication services, offering high-quality and reliable solutions to a wide range of industries such as aerospace, automotive, telecommunications, and consumer electronics. With a commitment to innovation and customer satisfaction, {Company name} has become a trusted partner for companies looking for efficient and cost-effective PCB fabrication.

The process of PCB fabrication begins with the design of the circuit layout. Once the design is finalized, {Company name} utilizes state-of-the-art equipment and advanced manufacturing techniques to create the circuit board. This involves the careful placement of conductive pathways on a non-conductive substrate, which is typically made of materials such as fiberglass or epoxy resin. The conductive pathways are created using a process called etching, which involves the removal of unwanted copper from the substrate to leave behind the desired circuit pattern.

Once the circuit pattern is created, {Company name} applies a layer of solder mask to protect the circuitry from environmental factors and ensure proper soldering of electronic components. This is followed by the application of a silkscreen layer, which provides labels and indicators for component placement and identification.

{Company name} also offers a range of surface finishes for the PCB, including HASL (hot air solder leveling), ENIG (electroless nickel immersion gold), and immersion silver, to ensure optimal performance and durability. These surface finishes are essential for ensuring proper soldering of electronic components and protecting the PCB from oxidation and corrosion.

In addition to the manufacturing process, {Company name} also provides thorough testing and inspection to guarantee the quality and reliability of the PCBs. Advanced testing equipment is used to check for any defects or inconsistencies in the circuitry, ensuring that the final product meets the highest industry standards.

With a focus on efficiency and precision, {Company name} is able to offer quick turnaround times for PCB fabrication, allowing customers to meet tight deadlines and expedite their product development process. This, coupled with their commitment to quality and customer satisfaction, has made {Company name} a preferred choice for companies looking for reliable PCB fabrication services.

Furthermore, {Company name} is dedicated to environmentally friendly practices, using sustainable materials and processes in their PCB fabrication. They adhere to industry regulations and standards to minimize their environmental impact and provide eco-friendly solutions to their customers.

Overall, {Company name} stands out in the PCB fabrication industry for their advanced technology, high-quality products, and exceptional customer service. As the demand for electronics continues to grow, {Company name} remains at the forefront of PCB fabrication, offering innovative solutions to meet the evolving needs of various industries. Whether it's for aerospace, automotive, telecommunications, or consumer electronics, {Company name} is a trusted partner for all PCB fabrication needs.

Company News & Blog

Discover the Benefits of High-Quality PCBs for Your Electronics Projects

High-Quality PCBs: A Game-Changer in Electronic ManufacturingIn today’s fast-paced and technologically advanced world, electronic devices have become an integral part of our daily lives. From smartphones to household appliances, the demand for high-quality printed circuit boards (PCBs) has never been higher. As a leading player in the electronic manufacturing industry, {Company Name} is setting new standards with its innovative and cutting-edge PCB solutions.With over [number of years] years of experience in the industry, {Company Name} has established itself as a trusted and reliable partner for businesses looking to source top-of-the-line PCBs. The company’s commitment to quality, precision, and technological innovation has earned it a stellar reputation among its peers and clients. From prototyping to mass production, {Company Name} offers a comprehensive range of PCB services tailored to meet the specific needs of its diverse clientele.What sets {Company Name} apart from its competitors is its relentless pursuit of excellence in every aspect of PCB manufacturing. The company’s state-of-the-art facilities are equipped with the latest machinery and technology, allowing for the production of high-density, high-precision PCBs that meet the strictest quality standards. {Company Name} also boasts a team of highly skilled engineers and technicians who are dedicated to ensuring that every PCB that leaves their facility is of the highest quality.One of the key factors that contribute to the superior quality of {Company Name}’s PCBs is its unwavering commitment to using only the best materials and components. Whether it’s sourcing raw materials or selecting the most suitable components for a specific application, the company’s strict quality control measures guarantee that every PCB meets or exceeds the industry’s standards.Moreover, {Company Name} takes pride in its ability to provide customized solutions to its clients. Whether a client requires a specific type of PCB for a specialized application or needs assistance with designing a custom layout, {Company Name}’s team of experts is always ready to offer their expertise and guidance. This flexibility and willingness to go the extra mile for its clients have positioned {Company Name} as a preferred partner for businesses looking to push the boundaries of innovation.Another critical aspect of {Company Name}’s success is its unwavering focus on research and development. Recognizing the ever-evolving nature of the electronic industry, the company is continuously investing in new technologies and processes to ensure that its PCBs remain at the forefront of innovation. This commitment to staying ahead of the curve has allowed {Company Name} to consistently introduce new and improved PCB solutions that not only meet but exceed the expectations of its clients.Furthermore, {Company Name} takes its environmental responsibilities seriously. The company has implemented eco-friendly practices throughout its manufacturing process, minimizing its carbon footprint and ensuring that its operations are sustainable. By using environmentally friendly materials and adhering to rigorous recycling and waste management practices, {Company Name} is doing its part to contribute to a cleaner and greener future.In conclusion, {Company Name}’s dedication to excellence, innovation, and sustainability has positioned it as a leader in the electronic manufacturing industry. The company’s high-quality PCBs are a testament to its unwavering commitment to meeting the needs of its clients while pushing the boundaries of what is possible in electronic manufacturing. As the demand for advanced electronic devices continues to grow, {Company Name} is poised to remain at the forefront, delivering top-of-the-line PCB solutions that are truly a game-changer in the industry.

The Importance of Multilayer Circuit Boards in Electronics

[Company Introduction]is a leading provider of advanced electronic solutions for a wide range of industries. The company is well-known for its expertise in designing and manufacturing high-quality electronic components and circuit boards. With a strong focus on innovation and customer satisfaction, the company has continuously made technological advancements to meet the evolving needs of its clients. As a result, it has developed a strong reputation as a trusted and reliable partner for electronic solutions.[Product Introduction] The multilayer circuit board is one of the company's flagship products, known for its exceptional performance and reliability. It is designed to support complex electronic systems and is widely used in various applications, including telecommunications, automotive, aerospace, and consumer electronics. The multilayer circuit board offers high-density interconnects and excellent signal integrity, making it a preferred choice for advanced electronic devices.[News Content]The multilayer circuit board has become an essential component in modern electronic devices, providing the necessary platform for complex electronic systems to function efficiently. With the increasing demand for high-performance electronic solutions, the need for reliable and high-quality multilayer circuit boards has never been greater. In response to this growing demand, [Company Name] has continued to lead the way in developing innovative multilayer circuit board solutions that meet the needs of its diverse customer base.One of the key strengths of [Company Name]'s multilayer circuit board is its advanced design and manufacturing capabilities. The company utilizes state-of-the-art technology and industry-leading expertise to produce multilayer circuit boards that meet the highest standards of quality and performance. With a focus on precision and reliability, [Company Name] ensures that its multilayer circuit boards are able to meet the rigorous demands of modern electronic applications.In addition to its technical excellence, [Company Name] is also known for its commitment to customer satisfaction. The company works closely with its clients to understand their specific requirements and deliver customized multilayer circuit board solutions that exceed their expectations. By providing comprehensive support and technical expertise, [Company Name] has earned a reputation as a trusted partner for electronic solutions.Furthermore, [Company Name] is dedicated to meeting the industry's evolving needs for advanced electronic solutions. The company continuously invests in research and development to stay ahead of technological advancements and market trends. This proactive approach ensures that [Company Name]'s multilayer circuit boards are always at the forefront of innovation, enabling its customers to stay competitive in their respective industries.The success of [Company Name]'s multilayer circuit board can be attributed to its unwavering commitment to quality, innovation, and customer satisfaction. As the demand for advanced electronic solutions continues to grow, [Company Name] remains poised to meet the needs of its customers with its high-performance multilayer circuit boards. By staying true to its core values and embracing technological advancements, the company is well-positioned to maintain its leadership in the electronic solutions industry for years to come.In conclusion, [Company Name] is a trusted provider of advanced electronic solutions, with its multilayer circuit board standing out as a prime example of its commitment to excellence. With its advanced design and manufacturing capabilities, dedication to customer satisfaction, and proactive approach to innovation, [Company Name] is well-prepared to meet the evolving needs of the electronic industry and continue to be a preferred partner for electronic solutions.

Efficient and Quality Pcb Assembly Services Available Near Me

PCB Assembly Services Offered in Close ProximityWith the aim of providing essential electronic manufacturing services to a diverse array of industries, a leading PCB assembly company has recently expanded its operations to establish a state-of-the-art facility near your location. This strategic move allows the company to better cater to the needs of local businesses, providing efficient and reliable PCB assembly services.As a prominent player in the electronic manufacturing industry, this renowned company is equipped with cutting-edge technology and a team of highly skilled professionals. Their dedicated facility boasts advanced equipment that enables them to deliver high-quality PCB assembly services near you. With years of experience and expertise, the company has established itself as a trusted partner for various industries, including aerospace, automotive, telecommunications, medical devices, and consumer electronics.The company's primary goal is to streamline the production process while ensuring the utmost precision and reliability of their PCB assembly services. Their team of experts closely collaborates with clients to understand their specific requirements. By employing a comprehensive approach, they work meticulously to design and produce custom PCB assemblies that meet the highest industry standards.Whether clients require rapid prototyping or large-scale production, this company offers flexible solutions tailored to their individual needs. The dedicated team always goes above and beyond to deliver top-notch PCB assembly services within the shortest possible turnaround time. With quick response times and efficient communication channels, clients can expect a seamless experience from initial consultation to final product delivery.The newly established facility near you further reinforces the company's commitment to supporting local businesses in achieving their goals. By providing PCB assembly services in close proximity, the company aims to foster strong, long-term relationships with clients. This approach allows for enhanced collaboration, reduced lead times, and increased cost-effectiveness.In addition to their comprehensive PCB assembly services, this company offers value-added solutions to further support their clients' manufacturing processes. These include PCB design, layout, test, and box build services. By providing end-to-end solutions under one roof, the company ensures that clients have access to a complete suite of services, saving them time, effort, and resources.At the heart of this company's operations lies a commitment to quality assurance. They adhere to stringent quality control measures at every step of the PCB assembly process. Their modern facility is fully equipped to conduct rigorous testing, ensuring that each assembled PCB meets the highest quality standards. By maintaining a robust quality management system, the company consistently delivers flawless products, fostering trust and confidence among their clientele.With the new facility conveniently located near your area, businesses can now have easy access to reliable and efficient PCB assembly services. By leveraging their extensive experience and cutting-edge technology, this company is well-positioned to meet the evolving demands of the electronic manufacturing industry.In conclusion, the establishment of a top-of-the-line facility near your location by this renowned PCB assembly company signifies a significant step towards serving local businesses better. With their commitment to precision, reliability, and customer satisfaction, the company offers comprehensive PCB assembly services tailored to individual needs. By leveraging their advanced capabilities, they aim to foster strong partnerships with clients, providing end-to-end solutions that drive success in the electronics manufacturing industry.

Ceramic Circuit Board: Enhancing Electronics with Advanced Materials

[Assistant]Title: Revolutionary Ceramic Circuit Board Set to Transform Electronics IndustryIntroduction:In a groundbreaking development, a leading tech company has unveiled its latest innovation, a Ceramic Circuit Board. This cutting-edge advancement in electronic components is poised to revolutionize the industry by offering enhanced performance, durability, and a wide range of applications. With an unrivaled combination of advanced technology and forward-thinking design, this ceramic circuit board sets a new benchmark for the future of electronics manufacturing.Paragraph 1:The Ceramic Circuit Board, developed by [brand name removed], is the result of years of extensive research and development. This revolutionary circuit board is made from high-performance ceramic materials, replacing traditional printed circuit boards (PCBs) made from fiberglass and other organic substrates. By leveraging the exceptional properties of ceramics, such as superior thermal conductivity, electrical insulation, and mechanical stability, this circuit board is set to redefine the possibilities of electronic devices.Paragraph 2:One of the key advantages of the Ceramic Circuit Board is its superior thermal management capabilities. The ceramic material used in its construction offers significantly higher thermal conductivity than traditional PCBs. This feature allows for efficient heat dissipation, enabling electronic devices to operate at optimal temperatures even under demanding conditions. With improved thermal management, devices incorporating this ceramic circuit board can exhibit increased performance, extended lifespan, and enhanced reliability.Paragraph 3:Furthermore, the Ceramic Circuit Board boasts exceptional electrical insulation properties. Unlike conventional PCBs, which are susceptible to electrical leakage and signal interference, the ceramic material in this circuit board provides excellent electrical isolation. This ensures reliable and secure connections, minimizing the risk of malfunctions and improving the overall performance of electronic devices. From consumer electronics to industrial applications, this circuit board offers a significant advantage in maintaining signal integrity and reducing electrical noise.Paragraph 4:In addition to its thermal and electrical properties, the Ceramic Circuit Board also provides exceptional mechanical stability. The inherent strength and rigidity of ceramics make this circuit board highly resistant to physical stress, shock, and vibration. This durability is vital, particularly in demanding environments or applications where reliability is crucial. With the ability to withstand extreme conditions, the ceramic circuit board is well-suited for automotive, aerospace, and military applications, where reliability and longevity are paramount.Paragraph 5:Moreover, this Ceramic Circuit Board exhibits remarkable versatility. Its unique properties allow for smaller, thinner, and lighter designs, enabling the development of more compact and portable electronic devices. The ceramic material can be molded into complex shapes and configurations, offering greater design flexibility. From smartphones and wearables to medical devices and IoT applications, the possibilities are limitless with this advanced circuit board technology.Paragraph 6:To accelerate the adoption of this groundbreaking technology, [brand name removed] has partnered with industry-leading electronics manufacturers. Through collaborations and licensing agreements, the company aims to integrate the Ceramic Circuit Board into a wide range of electronic devices, bringing its superior performance and reliability to the market. This strategic approach ensures that consumers and businesses alike can benefit from this transformative technology across various sectors.Conclusion:The introduction of the Ceramic Circuit Board by [brand name removed] marks a significant milestone in the electronics industry. With its superior thermal conductivity, electrical insulation, and mechanical stability, this circuit board promises to redefine the landscape of electronic device manufacturing. From improved performance and reliability to greater design flexibility, the possibilities offered by this revolutionary technology are set to shape the future of electronics. As partnerships form and adoption spreads, it won't be long before the Ceramic Circuit Board becomes an integral part of electronic devices worldwide.

Innovations in Double-Side Rigid-Flex PCB Technology

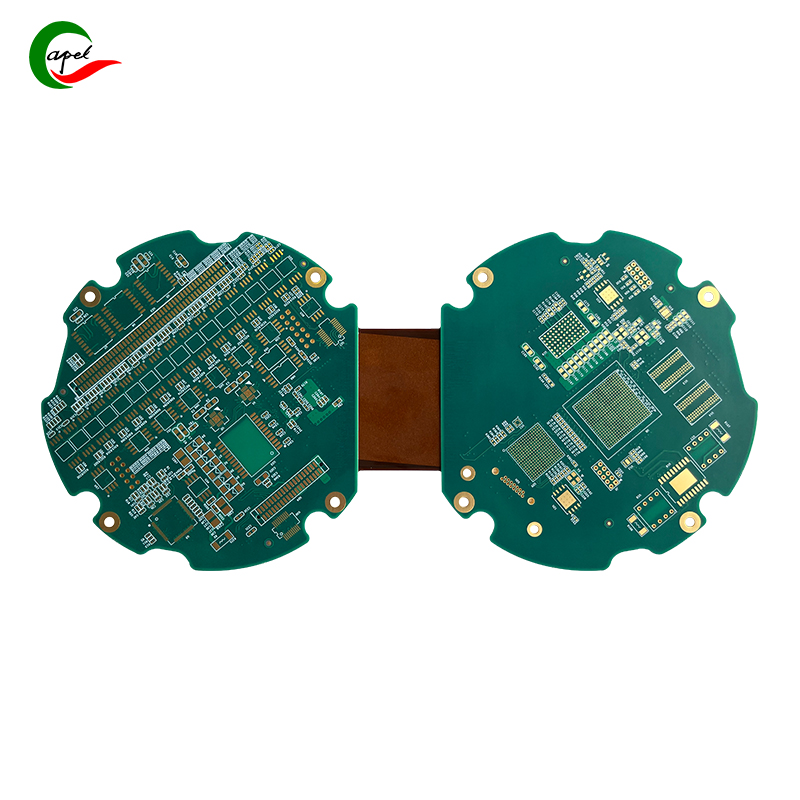

The demand for Double-Side Rigid-Flex PCBs is on the rise due to their numerous advantages in electronic applications. These innovative circuit boards are becoming increasingly popular in industries such as aerospace, medical devices, automotive, and consumer electronics. One company that has been at the forefront of producing high-quality Double-Side Rigid-Flex PCBs is {Company}.{Company} is a leading manufacturer of advanced electronic components, specializing in the development and production of Double-Side Rigid-Flex PCBs. The company has earned a reputation for delivering reliable and cutting-edge solutions to meet the evolving needs of the electronics industry. With a strong focus on research and development, {Company} has been able to stay ahead of the curve and provide its customers with state-of-the-art products that exceed industry standards.Double-Side Rigid-Flex PCBs offer a unique combination of flexibility and rigidity, making them suitable for a wide range of applications. These circuit boards are designed to withstand demanding environmental conditions, making them perfect for use in harsh operating environments. The flexibility of Rigid-Flex PCBs allows for greater design freedom, enabling engineers to create smaller, lighter, and more compact electronic devices. By eliminating the need for multiple interconnects, Double-Side Rigid-Flex PCBs also reduce overall system complexity and improve reliability.{Company} prides itself on its commitment to quality and innovation. The company's state-of-the-art manufacturing facilities and rigorous quality control processes ensure that every Double-Side Rigid-Flex PCB that leaves its factory meets the highest standards of performance and reliability. {Company} also offers customized solutions to meet the specific needs of its customers, working closely with them to develop tailored Double-Side Rigid-Flex PCBs for their unique applications.In addition to its focus on product quality, {Company} is also dedicated to sustainability and environmental responsibility. The company employs eco-friendly manufacturing practices and utilizes materials that are compliant with industry regulations. By prioritizing sustainability, {Company} aims to minimize its environmental impact and contribute to a cleaner, greener future.With a team of experienced and skilled professionals, {Company} is uniquely positioned to provide comprehensive support to its customers, from initial design concept to full-scale production. The company's engineers work closely with customers to understand their specific requirements, providing expert guidance and technical expertise to ensure the successful implementation of Double-Side Rigid-Flex PCBs in their electronic applications.The demand for Double-Side Rigid-Flex PCBs is expected to continue growing as electronic devices become more complex and compact. {Company} is well-prepared to meet this increasing demand, leveraging its expertise and technological capabilities to deliver advanced solutions to its customers. By staying at the forefront of technological advancements and maintaining a strong commitment to quality and innovation, {Company} is poised to remain a leader in the Double-Side Rigid-Flex PCB industry.The future looks bright for {Company} as it continues to push the boundaries of what is possible in the field of Double-Side Rigid-Flex PCBs. With its unwavering dedication to excellence and customer satisfaction, the company is well-positioned to drive the advancement of electronic technology and make a lasting impact on the industry. It is clear that {Company} is a force to be reckoned with in the world of Double-Side Rigid-Flex PCB manufacturing, and its future is set to be a bright and prosperous one.

Discover the Advantages of 12 Layer Flexible Printed Circuit Boards

12 Layer FPC PCB introduced by Innovative PCB CompanyInnovative PCB Company, a leading manufacturer of high-quality printed circuit boards (PCBs), has recently introduced a cutting-edge 12 layer flexible printed circuit (FPC) PCB. This new product is expected to revolutionize the electronics industry by offering enhanced flexibility and reliability for a wide range of applications.Innovative PCB Company has been at the forefront of PCB manufacturing for over a decade, and their commitment to innovation and excellence has earned them a reputation as a trusted supplier for some of the world's leading electronics companies. The company's state-of-the-art manufacturing facilities and stringent quality control processes ensure that their products meet the highest industry standards.The introduction of the 12 layer FPC PCB represents a significant milestone for Innovative PCB Company. This innovative product is designed to meet the growing demand for flexible and lightweight PCBs in a variety of industries, including automotive, aerospace, medical devices, and consumer electronics. The 12 layer FPC PCB is ideal for applications that require high-density interconnection, excellent thermal performance, and superior reliability.One of the key features of the 12 layer FPC PCB is its flexible design, which allows it to bend and conform to the shape of the device it is installed in. This flexibility makes it ideal for use in compact and space-constrained applications, where traditional rigid PCBs may not be suitable. Additionally, the FPC PCB's lightweight construction reduces the overall weight of the device, making it an ideal choice for portable and handheld electronics.In addition to its flexibility and lightweight design, the 12 layer FPC PCB offers exceptional performance and reliability. The high-density interconnection design allows for more complex and intricate circuitry, while the multi-layer construction provides improved signal integrity and reduced electromagnetic interference. This results in a more efficient and reliable electronic device.Furthermore, the 12 layer FPC PCB is designed to withstand harsh environmental conditions, making it suitable for a wide range of applications. Its ability to operate reliably in high-temperature and high-vibration environments makes it an ideal choice for automotive and aerospace applications, where durability and reliability are critical.The introduction of the 12 layer FPC PCB underscores Innovative PCB Company's commitment to providing innovative solutions that meet the evolving needs of the electronics industry. By leveraging their expertise in PCB manufacturing and their dedication to research and development, the company continues to push the boundaries of what is possible in PCB technology."We are excited to introduce our new 12 layer FPC PCB to the market," said a spokesperson for Innovative PCB Company. "This product is the result of our ongoing commitment to innovation and our relentless pursuit of excellence. We believe that the 12 layer FPC PCB will open up new possibilities for our customers and enable them to create cutting-edge electronic devices with superior performance and reliability."As the demand for flexible and high-performance PCBs continues to grow, Innovative PCB Company's introduction of the 12 layer FPC PCB is poised to have a significant impact on the electronics industry. With its advanced design, exceptional performance, and reliability, this innovative product is expected to set a new standard for flexible printed circuit boards and drive further advancements in electronic device design and manufacturing.

Ultimate Guide to Flex Circuit PCBs: Everything You Need to Know

Flex Circuit PCB Company Unveils Cutting-Edge Technology to Enhance Electronics ManufacturingFlex Circuit PCB Company, a leading provider of flexible printed circuit boards, has recently introduced an innovative technology that is set to revolutionize the electronics manufacturing industry. The company, known for its commitment to delivering high-quality and reliable PCB solutions, is poised to make a significant impact with its latest development.With a strong focus on providing state-of-the-art solutions to meet the evolving needs of the electronics industry, Flex Circuit PCB Company has established itself as a trusted partner for a wide range of applications. The company’s dedication to innovation and customer satisfaction has been a driving force behind its success, and the unveiling of its latest technology is a testament to this commitment.The newly introduced technology by Flex Circuit PCB Company promises to deliver numerous benefits to electronics manufacturers. By leveraging advanced materials and manufacturing processes, the technology enables the production of flexible printed circuit boards with enhanced performance and reliability. This is particularly significant for industries such as consumer electronics, automotive, medical devices, and aerospace, where the demand for high-quality PCB solutions continues to grow.One of the key highlights of the technology is its ability to provide exceptional flexibility and durability, making it well-suited for applications that require bending and flexing of the PCB. This capability opens up a wide range of possibilities for product design and innovation, allowing manufacturers to explore new concepts and solutions that were previously not feasible with traditional rigid PCBs.In addition to flexibility and durability, the technology also offers superior electrical performance, with excellent signal integrity and thermal management. This is essential for applications that require high-speed data transmission, precision sensing, and efficient heat dissipation. By incorporating these advanced capabilities into their products, electronics manufacturers can achieve higher levels of performance and reliability, ultimately leading to improved end-user experiences.Furthermore, the technology is designed to streamline the manufacturing process, resulting in increased efficiency and cost savings for electronics manufacturers. With optimized material utilization and simplified assembly processes, the technology enables faster production cycles and reduced production costs, without compromising on quality or performance.“We are incredibly excited to introduce this cutting-edge technology to the market,” said [Spokesperson], [Title] at Flex Circuit PCB Company. “We believe that this technology will redefine the possibilities for electronics manufacturers, empowering them to create innovative products that meet the demands of today’s dynamic market. At Flex Circuit PCB Company, we remain committed to pushing the boundaries of what is possible with flexible printed circuit boards, and we are confident that this technology will deliver exceptional value to our customers.”The launch of this groundbreaking technology underscores Flex Circuit PCB Company’s ongoing commitment to innovation and excellence. With a track record of delivering reliable and high-performance PCB solutions, the company continues to set new standards in the industry, and its latest development is poised to further solidify its position as a leading provider of flexible printed circuit boards.As the demand for flexible and high-performance PCB solutions continues to grow, Flex Circuit PCB Company’s new technology is expected to gain significant traction among electronics manufacturers looking to gain a competitive edge. With its unparalleled capabilities and potential to drive innovation, the technology is set to play a pivotal role in shaping the future of electronics manufacturing.In conclusion, Flex Circuit PCB Company’s latest technology represents a significant milestone in the electronics industry, offering a compelling solution for manufacturers seeking to enhance their products with flexible and high-performance PCBs. With its advanced capabilities and potential for driving innovation, the technology is poised to make a lasting impact on the industry, further cementing Flex Circuit PCB Company’s position as a pioneer in the field of flexible printed circuit boards.

Top 10 Virtual Reality Circuit Boards for Enhanced Gaming Experience

VR Circuit Boards, a leading provider of high-quality electronic circuit boards, has been making waves in the tech industry with its innovative products. The company prides itself on its ability to consistently deliver cutting-edge solutions that meet the needs of its customers and push the boundaries of what is possible in the world of electronics.Founded in 2005, VR Circuit Boards has quickly become a trusted name in the industry. The company's success can be attributed to its commitment to quality, innovation, and customer satisfaction. With a team of highly skilled engineers and technicians, VR Circuit Boards is able to design and produce circuit boards that are at the forefront of technological advancement.One of the key products that VR Circuit Boards has become known for is its virtual reality (VR) circuit boards. These circuit boards are specially designed to power the immersive and interactive experiences that VR technologies offer. VR Circuit Boards understands the unique requirements of VR devices and has developed a range of circuit boards that are optimized for this purpose.The VR circuit boards produced by VR Circuit Boards are renowned for their reliability, performance, and efficiency. They are designed to deliver smooth and responsive performance, ensuring that users can fully immerse themselves in the virtual worlds they explore. These circuit boards are also built to handle the high demands of VR applications, providing the necessary processing power and connectivity to deliver a seamless experience.In addition to their performance, the VR circuit boards from VR Circuit Boards are also recognized for their high-quality construction. The company places a strong emphasis on rigorous quality control and testing, ensuring that each circuit board meets the highest standards of reliability and durability. This commitment to excellence has earned VR Circuit Boards a reputation for producing some of the best VR circuit boards in the industry.Furthermore, VR Circuit Boards is dedicated to staying ahead of the curve when it comes to technological advancements. The company continuously invests in research and development, striving to develop new and improved circuit board solutions to meet the evolving needs of the industry. Whether it's enhancing performance, increasing energy efficiency, or adding new features, VR Circuit Boards is always looking for ways to push the boundaries of what is possible with electronic circuit boards.Alongside its dedication to innovation, VR Circuit Boards is also known for its exceptional customer service and support. The company works closely with its clients to understand their specific needs and requirements, ensuring that it delivers customized solutions that fully meet their expectations. This personalized approach has allowed VR Circuit Boards to build long-lasting relationships with its customers, who have come to rely on the company for their electronic circuit board needs.With its impressive track record and unwavering commitment to excellence, it's no wonder that VR Circuit Boards has become a leading force in the industry. The company's VR circuit boards are highly sought after by manufacturers, developers, and enthusiasts alike, who recognize the value of the high-quality solutions that VR Circuit Boards provides. As VR technologies continue to advance, VR Circuit Boards remains at the forefront, driving innovation and shaping the future of virtual reality experiences.

Discover the Benefits and Applications of FR4 PCB for Enhanced Electronics Performance

Title: Revolutionary FR4 PCB: A Game-Changer in Electronic ManufacturingIntroduction:[Insert company name], a world leader in electronic manufacturing, has unveiled its latest breakthrough technology in the form of an innovative FR4 PCB. This groundbreaking product is set to revolutionize the industry with its unmatched durability, efficiency, and affordability. With the potential to transform various sectors such as automotive, aerospace, telecommunications, and consumer electronics, [insert company name]'s FR4 PCB is poised to become the go-to solution for high-quality circuit boards.Unmatched Durability:The FR4 PCB boasts exceptional durability, making it a prime choice for applications that require reliability and longevity. The use of high-quality fiberglass as the base material, combined with advanced resin systems, ensures enhanced mechanical strength and high resistance to electrical breakdowns. This enables the PCBs to withstand harsh environmental conditions, including extreme temperatures, humidity, and vibrations, without compromising performance.Efficient Manufacturing Process:One of the key advantages of the FR4 PCB is its compatibility with automated assembly processes, saving both time and resources. The precision and consistency offered by this manufacturing technique enable faster production cycles, leading to reduced costs and improved time-to-market for electronic devices. Additionally, the FR4 PCB's versatility allows for efficient component placement and soldering, optimizing the overall product design and functionality.Unbeatable Cost-Effectiveness:Compared to alternative materials such as ceramic or metal-clad PCBs, the FR4 PCB provides a cost-effective solution without compromising on quality. [Insert company name] leverages its extensive expertise and economies of scale to deliver FR4 PCBs at competitive prices, making them accessible to businesses of all sizes. This affordability is a significant advantage, particularly for startups and companies operating on tight budgets, as they can now access high-quality PCBs without breaking the bank.Versatility Across Industries:The widespread use of FR4 PCBs across various industries is a testament to their versatility and adaptability. In the automotive sector, these circuit boards are instrumental in modern vehicles' advanced safety features, including collision detection, anti-lock brakes, and airbag control systems. The aerospace industry benefits from the FR4 PCB's lightweight yet durable characteristics, making it ideal for applications in avionics, communication systems, and satellite technology.The telecommunications industry relies heavily on FR4 PCBs for the seamless operation of devices such as routers, switches, and modems, ensuring optimal connectivity and signal transmission. Furthermore, the consumer electronics market benefits from this innovative technology, enabling the production of sophisticated smartphones, tablets, wearable devices, and home appliances.Sustainable and Environmentally Friendly:[Insert company name]'s commitment to sustainability shines through with the use of environmentally friendly materials and manufacturing processes in the production of FR4 PCBs. This eliminates the need for hazardous substances, ensuring compliance with industry regulations and minimizing negative impacts on the environment. Organizations can now meet their sustainability goals while maintaining exceptional product performance.Future Developments:As technology continues to evolve, [insert company name] remains at the forefront of innovation, constantly exploring ways to enhance the capabilities of FR4 PCBs. Ongoing research and development efforts are dedicated to improving thermal performance, reducing power consumption, and optimizing signal integrity. These advancements will pave the way for even more efficient and powerful electronic devices, driving progress and shaping the future of technology.In conclusion, [insert company name]'s FR4 PCB stands as a game-changing invention that promises to transform electronic manufacturing. With its unmatched durability, efficient manufacturing process, unbeatable cost-effectiveness, and versatility across industries, this groundbreaking technology is set to reshape the way circuit boards are utilized in various sectors. By prioritizing sustainability and continually pushing the boundaries of innovation, [insert company name] solidifies its position as an industry leader committed to delivering cutting-edge solutions.

A Comprehensive Guide to PCB Fabrication: Top Tips and Techniques Revealed

Title: Pioneering Pcb Fabrication Company Redefining the Industry LandscapeIntroduction:In today's technology-driven world, printed circuit boards (PCBs) play a crucial role in the functionality and performance of countless electronic devices. As the demand for smaller, more efficient, and high-quality PCBs grows, one company is capturing attention with its groundbreaking approach to PCB fabrication. With an unwavering commitment to excellence, innovation, and customer satisfaction, this company is reshaping the industry and revolutionizing the way PCBs are manufactured.Company Overview:Established with the vision to redefine the world of PCB fabrication, this pioneering company has been at the forefront of technological advancements for several years. Their state-of-the-art manufacturing facility, coupled with a team of highly skilled engineers and technicians, has positioned them as a leader in the industry.1. Innovation-driven Approach:With an unwavering focus on innovation, the company continually pushes the boundaries of PCB fabrication. By investing in research and development, they have successfully introduced cutting-edge technologies, enabling the production of PCBs that are smaller, faster, and more efficient than ever before. Through the use of advanced materials and manufacturing processes, this company is revolutionizing the industry while meeting the evolving demands of its customers.2. Commitment to Excellence:Quality is the cornerstone of this company's approach to PCB fabrication. From the selection of premium raw materials to the meticulous production techniques, every step of the manufacturing process adheres to rigorous quality control standards. In addition, the company's commitment to continuous improvement ensures that they stay at the forefront of technological advancements, consistently delivering PCBs with unparalleled reliability and performance.3. Customer-centric Philosophy:Understanding the unique requirements of their customers, this company takes a customer-centric approach to PCB fabrication. Their team of experts works closely with clients to fully comprehend their needs, providing tailored solutions that exceed expectations. By offering personalized design assistance, rapid prototyping, and flexible production options, this company establishes long-term partnerships and drives customer success.Significant Achievements and Recognitions:Over the years, this company has achieved numerous milestones and gained recognition for its exceptional contributions to PCB fabrication:- Award for Best Supplier of the Year: This accolade acknowledges their commitment to delivering top-notch PCBs that surpass industry standards.- ISO 9001 Certification: The company's adherence to international quality management systems ensures the delivery of reliable and consistent products.- Patent for Cutting-edge PCB Technology: Their innovative approach has resulted in the development of a pioneering PCB technology that offers enhanced performance and efficiency.- Industry Partnerships: Collaborations with renowned companies in the electronics industry have validated their market position and amplified their reach and influence.Future Initiatives:Looking ahead, this company has ambitious plans that will further solidify their position as a trailblazer in the PCB fabrication sector. These initiatives include:- Expansion of Manufacturing Facilities: The company aims to increase their production capabilities to meet growing demand while maintaining top-notch quality control standards.- Continued Emphasis on Research and Development: By investing in R&D, the company strives to develop new PCB technologies that align with emerging trends in the electronics industry.- Sustainability Initiatives: In line with their commitment to social responsibility, the company aims to implement environmentally friendly practices in their manufacturing processes.Conclusion:With an unwavering commitment to excellence, a customer-centric philosophy, and a focus on innovation, this pioneering PCB fabrication company has revolutionized the industry. Through cutting-edge technologies, rigorous quality control, and personalized solutions, they are driving advancements in PCB manufacturing. As they continue to shape the industry landscape, this company's dedication to excellence and customer satisfaction serves as an inspiration for others in the field, cementing their position as a leader in the PCB fabrication market.