How to Manufacture a Prototype PCB: Everything You Need to Know

By:Admin

The company specializes in the production of prototype and low-volume PCBs, offering a wide range of capabilities to meet the unique needs of its customers. From simple single-layer boards to complex multi-layer designs, Prototype PCB has the expertise and technology to produce high-quality PCBs for a variety of applications.

One of the key differentiators for Prototype PCB is its commitment to quality. The company employs a rigorous quality control process to ensure that every PCB it produces meets the highest standards of performance and reliability. With state-of-the-art manufacturing facilities and a team of experienced professionals, customers can trust that their PCBs will meet their exact specifications and requirements.

In addition to its manufacturing capabilities, Prototype PCB also offers a range of value-added services to support its customers throughout the PCB development process. This includes design for manufacturability (DFM) review, prototype assembly, and testing services. By offering these additional services, Prototype PCB aims to streamline the PCB development process and help its customers bring their products to market faster.

Another key strength of Prototype PCB is its commitment to customer service. The company understands that every project is unique, and it works closely with each customer to ensure that their specific needs are met. With a team of dedicated customer service professionals, Prototype PCB provides personalized support and guidance to help customers navigate the PCB manufacturing process.

In addition to its dedication to quality and customer service, Prototype PCB is also focused on innovation. The company continuously invests in new technologies and process improvements to stay at the forefront of PCB manufacturing. By leveraging the latest advancements in the industry, Prototype PCB is able to offer its customers the most advanced and reliable PCB solutions available.

As a result of its commitment to excellence, Prototype PCB has earned a reputation as a trusted partner for businesses across a wide range of industries. From electronics and telecommunications to medical devices and aerospace, Prototype PCB has the expertise and capabilities to support a diverse customer base.

Moving forward, Prototype PCB is committed to continuing its tradition of excellence and innovation. The company will continue to invest in new technologies, expand its capabilities, and enhance its customer service to better serve the evolving needs of the electronics industry.

For businesses in need of high-quality PCB manufacturing services, Prototype PCB is the go-to partner for reliable, innovative, and personalized solutions. With a focus on quality, customer service, and innovation, Prototype PCB is dedicated to helping its customers bring their electronic designs to life.

Company News & Blog

Top Pcb Manufacturers in China: A Comprehensive Guide

Chinese PCB Manufacturers Continue to Expand and InnovateWith the increasing demand for high-quality printed circuit boards (PCBs) in various industries, Chinese PCB manufacturers have been expanding their production capacity and investing in advanced technologies to stay ahead in the competitive market. One such leading PCB manufacturer, {company name}, has been making significant strides in the industry, continuously expanding its capabilities to meet the growing needs of its global customer base.Established in {year}, {company name} has quickly risen to prominence as a frontrunner in the PCB manufacturing sector. The company prides itself on its state-of-the-art facilities, highly skilled workforce, and dedication to delivering top-notch PCB solutions to clients across diverse industries, including telecommunications, automotive, consumer electronics, medical devices, and more.In line with the market trends and the fast-paced technological advancements, {company name} has been relentless in its pursuit of innovation and has consistently invested in cutting-edge technologies and equipment. This commitment to staying at the forefront of PCB manufacturing has allowed the company to produce high-quality PCBs with intricate designs, complex layering, and advanced functionalities, meeting the stringent requirements of modern electronic applications.Furthermore, {company name} has also focused on expanding its production capabilities to cater to the increasing demand for quick turnaround times and large-volume orders. The company has implemented efficient manufacturing processes and optimized its production lines to ensure timely delivery of PCBs without compromising on quality. This has earned {company name} a reputation for reliability and responsiveness in the industry.Additionally, to strengthen its position in the global market, {company name} has been actively seeking certifications and adhering to international standards for quality and environmental management systems. This has not only enhanced the company's credibility but has also allowed it to engage with a broader spectrum of clients who prioritize compliance and sustainability in their supply chain.In response to the growing emphasis on eco-friendly practices, {company name} has also made substantial efforts to incorporate green manufacturing processes and materials. By adopting sustainable practices, such as waste reduction, energy efficiency, and the use of environmentally friendly materials, the company has aligned itself with the evolving expectations of environmentally conscious customers and regulatory requirements.Furthermore, in an era where technological advancements are constantly reshaping the electronics industry, {company name} has recognized the importance of research and development to stay ahead of the curve. The company has established a dedicated R&D team that continuously explores new materials, manufacturing techniques, and design methodologies to enhance the performance and reliability of its PCBs. This forward-looking approach has enabled {company name} to introduce innovative PCB solutions that address the evolving needs of its clients.As part of its growth strategy, {company name} has also been actively expanding its global footprint to better serve its international clientele. By establishing strategic partnerships and setting up sales and support facilities in key regions, the company has been able to provide localized services and technical expertise to customers around the world, fostering long-term relationships and customer satisfaction.Looking ahead, {company name} remains committed to pushing the boundaries of PCB manufacturing excellence, embracing new technologies, and adapting to the changing needs of the electronics industry. With a strong focus on innovation, quality, and customer-centricity, the company is poised to continue its upward trajectory and solidify its position as a leading PCB manufacturer in the global market.In conclusion, the continued expansion and innovation of Chinese PCB manufacturers such as {company name} reflect their determination to set new benchmarks for excellence in the industry. Through their relentless pursuit of technological advancements, quality assurance, and sustainable practices, these manufacturers are not only meeting the current demands of their clients but also shaping the future of PCB manufacturing. As the electronics industry evolves, the contributions of these manufacturers will undoubtedly play a pivotal role in driving innovation and progress in electronic applications worldwide.

A Comprehensive Guide to PCB Fabrication: Top Tips and Techniques Revealed

Title: Pioneering Pcb Fabrication Company Redefining the Industry LandscapeIntroduction:In today's technology-driven world, printed circuit boards (PCBs) play a crucial role in the functionality and performance of countless electronic devices. As the demand for smaller, more efficient, and high-quality PCBs grows, one company is capturing attention with its groundbreaking approach to PCB fabrication. With an unwavering commitment to excellence, innovation, and customer satisfaction, this company is reshaping the industry and revolutionizing the way PCBs are manufactured.Company Overview:Established with the vision to redefine the world of PCB fabrication, this pioneering company has been at the forefront of technological advancements for several years. Their state-of-the-art manufacturing facility, coupled with a team of highly skilled engineers and technicians, has positioned them as a leader in the industry.1. Innovation-driven Approach:With an unwavering focus on innovation, the company continually pushes the boundaries of PCB fabrication. By investing in research and development, they have successfully introduced cutting-edge technologies, enabling the production of PCBs that are smaller, faster, and more efficient than ever before. Through the use of advanced materials and manufacturing processes, this company is revolutionizing the industry while meeting the evolving demands of its customers.2. Commitment to Excellence:Quality is the cornerstone of this company's approach to PCB fabrication. From the selection of premium raw materials to the meticulous production techniques, every step of the manufacturing process adheres to rigorous quality control standards. In addition, the company's commitment to continuous improvement ensures that they stay at the forefront of technological advancements, consistently delivering PCBs with unparalleled reliability and performance.3. Customer-centric Philosophy:Understanding the unique requirements of their customers, this company takes a customer-centric approach to PCB fabrication. Their team of experts works closely with clients to fully comprehend their needs, providing tailored solutions that exceed expectations. By offering personalized design assistance, rapid prototyping, and flexible production options, this company establishes long-term partnerships and drives customer success.Significant Achievements and Recognitions:Over the years, this company has achieved numerous milestones and gained recognition for its exceptional contributions to PCB fabrication:- Award for Best Supplier of the Year: This accolade acknowledges their commitment to delivering top-notch PCBs that surpass industry standards.- ISO 9001 Certification: The company's adherence to international quality management systems ensures the delivery of reliable and consistent products.- Patent for Cutting-edge PCB Technology: Their innovative approach has resulted in the development of a pioneering PCB technology that offers enhanced performance and efficiency.- Industry Partnerships: Collaborations with renowned companies in the electronics industry have validated their market position and amplified their reach and influence.Future Initiatives:Looking ahead, this company has ambitious plans that will further solidify their position as a trailblazer in the PCB fabrication sector. These initiatives include:- Expansion of Manufacturing Facilities: The company aims to increase their production capabilities to meet growing demand while maintaining top-notch quality control standards.- Continued Emphasis on Research and Development: By investing in R&D, the company strives to develop new PCB technologies that align with emerging trends in the electronics industry.- Sustainability Initiatives: In line with their commitment to social responsibility, the company aims to implement environmentally friendly practices in their manufacturing processes.Conclusion:With an unwavering commitment to excellence, a customer-centric philosophy, and a focus on innovation, this pioneering PCB fabrication company has revolutionized the industry. Through cutting-edge technologies, rigorous quality control, and personalized solutions, they are driving advancements in PCB manufacturing. As they continue to shape the industry landscape, this company's dedication to excellence and customer satisfaction serves as an inspiration for others in the field, cementing their position as a leader in the PCB fabrication market.

Ultimate Guide to Double Sided PCBs: Benefits, Applications, and Manufacturing

Double-Sided PCB: A Breakthrough in Electronics ManufacturingIn the ever-evolving world of electronics manufacturing, the use of double-sided PCBs has proven to be a game changer. This innovative technology has revolutionized the way electronic devices are designed and manufactured, allowing for greater flexibility, efficiency, and cost-effectiveness in the production process.A double-sided PCB, as the name suggests, is a printed circuit board with circuitry on both sides of the board. This allows for increased routing density and enables more complex circuit designs to be implemented in a smaller space. With advancements in manufacturing processes and materials, double-sided PCBs have become a preferred choice for a wide range of electronic applications, from consumer electronics to industrial equipment.One company at the forefront of this technological advancement is the visionary team at [Company Name]. With a history of innovation and a commitment to excellence, [Company Name] has been a driving force in the development and adoption of double-sided PCB technology.Founded in [year], [Company Name] has consistently pushed the boundaries of conventional PCB manufacturing, striving to provide cutting-edge solutions to its global customer base. With state-of-the-art facilities and a dedicated team of engineers and technicians, the company has earned a reputation for delivering high-quality PCB products that meet the ever-increasing demands of the electronics industry.The use of double-sided PCBs has enabled [Company Name] to offer its customers a range of benefits, including:1. Enhanced Design Flexibility: With double-sided PCBs, designers have the freedom to create more intricate and compact circuit layouts, making it possible to pack greater functionality into smaller form factors.2. Improved Signal Integrity: By allowing for more efficient routing of signals, double-sided PCBs help to minimize signal interference and maintain the integrity of the electronic device's performance.3. Cost Efficiency: The use of double-sided PCBs can reduce the overall size and complexity of the electronic device, leading to cost savings in materials and assembly processes.4. Versatility: Double-sided PCBs are well-suited for a wide range of electronic applications, from simple consumer devices to complex industrial machinery, making them a versatile choice for manufacturers across various industries.The adoption of double-sided PCB technology has also positioned [Company Name] as a leader in the sustainable manufacturing of electronic components. By maximizing the use of space and materials, double-sided PCBs contribute to the reduction of waste and environmental impact, aligning with [Company Name]'s commitment to corporate social responsibility.In addition to its technological advancements, [Company Name] has also demonstrated a commitment to customer satisfaction and collaboration. The company's team of experts works closely with customers to understand their specific needs and provide tailored solutions that meet or exceed their expectations. This customer-centric approach has led to long-lasting partnerships with clients from diverse industries, cementing [Company Name]'s position as a trusted and reliable PCB manufacturer.Looking ahead, [Company Name] remains dedicated to pushing the boundaries of innovation in PCB manufacturing. The company continues to invest in research and development, exploring new materials, processes, and technologies that will further enhance the performance and capabilities of double-sided PCBs. By staying at the forefront of industry trends and customer needs, [Company Name] is poised to lead the way in shaping the future of electronics manufacturing.In conclusion, the use of double-sided PCB technology has brought about a significant shift in the electronics manufacturing landscape, and [Company Name] stands at the forefront of this exciting revolution. With its unwavering commitment to innovation, quality, and customer satisfaction, [Company Name] is well-positioned to continue driving the advancement of double-sided PCB technology and delivering cutting-edge solutions to the global electronics industry.

How Circuit Boards are Manufactured and its Uses

Smt Circuit Board Company Introduces Cutting-Edge TechnologySmt Circuit Board, a leading manufacturer of high-quality printed circuit boards, is revolutionizing the industry with the introduction of their state-of-the-art production technology. The company, with its headquarters in (location), has been at the forefront of innovation for over a decade, and their latest technological advancement is set to further cement their position as a pioneer in the field.The new technology, which the company has developed in-house, promises to significantly enhance the efficiency and precision of the manufacturing process. Through the integration of advanced robotics and automated systems, Smt Circuit Board has been able to achieve unprecedented levels of accuracy and consistency in the production of their circuit boards. This breakthrough will not only enable the company to meet the growing demand for their products but also to exceed the expectations of their customers in terms of quality and reliability.In addition to improving the manufacturing process, Smt Circuit Board's new technology also has the potential to reduce production costs, making their products more competitive in the market. By streamlining operations and minimizing the margin for error, the company anticipates being able to offer their cutting-edge circuit boards at more competitive prices, thereby further increasing their appeal to existing and prospective customers."We are thrilled to announce the launch of our latest technological innovation," said the CEO of Smt Circuit Board. "We have always been committed to pushing the boundaries of what is possible in the world of printed circuit board manufacturing, and this new development is a testament to that commitment. We believe that this technology will not only benefit our company but also the entire industry as a whole, by setting a new standard for excellence and efficiency."The company's dedication to innovation and excellence is further reflected in their commitment to sustainability. Smt Circuit Board has made substantial investments in environmentally friendly production methods, and their new technology is no exception. By optimizing resource utilization and reducing waste, the company seeks to minimize their environmental footprint and contribute to a more sustainable future for the industry.Smt Circuit Board's cutting-edge technology has already garnered significant attention from industry insiders and experts, with many hailing it as a game-changer for the printed circuit board manufacturing sector. The company has already begun the process of integrating the new technology into their production facilities, and they expect to see tangible results in the near future."We are confident that this technology will position us as a leader in the industry and enable us to continue delivering superior products and services to our customers," said the CEO. "We are excited about the possibilities that this innovation opens up for us, and we look forward to the positive impact it will have on our business and the industry as a whole."As Smt Circuit Board prepares to roll out their groundbreaking new technology, the company is poised to reaffirm its position as a frontrunner in the printed circuit board manufacturing sector. With a track record of innovation, excellence, and customer satisfaction, Smt Circuit Board is set to continue leading the way in the industry for years to come.

FPC flexible PCB market trends and industry updates

FPC Flexible PCB: Revolutionizing Electronic CircuitryThe demand for smaller, more compact electronic devices has been on the rise in recent years, leading to an increased need for innovative technology that can accommodate these requirements. This is where FPC (flexible printed circuit) flexible PCB comes into play, offering a groundbreaking solution for electronic circuitry that can be bent and shaped to fit the specific design needs of a variety of electronic devices.One company at the forefront of this cutting-edge technology is {}. Established in {}, {} has been a pioneer in the development and production of flexible PCB solutions for a wide range of industries, including consumer electronics, automotive, aerospace, and medical devices.The key to {}'s success lies in its continuous research and development efforts, as well as its commitment to providing high-quality, reliable products to its customers. By leveraging state-of-the-art manufacturing processes and materials, the company has been able to produce flexible PCB solutions that meet the stringent requirements of modern electronic devices.One of the main advantages of FPC flexible PCB is its ability to conform to the shape of the device it is installed in, allowing for more efficient use of space and enabling the design of smaller, more lightweight products. This flexibility also contributes to improved reliability and durability, as traditional rigid PCBs are more prone to damage from bending and vibration.Another key benefit of FPC flexible PCB is its adaptability to complex and unconventional designs. This makes it an ideal choice for products that require intricate circuitry layouts, such as wearable technology, flexible displays, and IoT (Internet of Things) devices. The ability to create custom shapes and intricate routing patterns enables designers to push the boundaries of what is possible in electronic device design.In addition to its physical flexibility, FPC flexible PCB also offers superior electrical performance compared to traditional rigid PCBs. With lower electrical resistance and reduced signal loss, flexible PCBs enable the transmission of high-frequency signals with minimal interference, making them suitable for high-speed and high-frequency applications.Furthermore, {}'s FPC flexible PCB solutions are also designed to withstand harsh environmental conditions, such as temperature variations, moisture, and chemical exposure. This makes them well-suited for use in automotive, aerospace, and industrial applications, where reliability and resilience are paramount.Despite the many advantages of FPC flexible PCB, the technology is still relatively new and not yet widely adopted in all industries. However, as the demand for smaller, more innovative electronic devices continues to grow, it is expected that the market for flexible PCBs will expand rapidly in the coming years.In anticipation of this growth, {} is continuing to invest in research and development to further improve the performance and capabilities of its flexible PCB solutions. By staying ahead of the curve and investing in the future of electronic circuitry, {} aims to remain a leader in the flexible PCB industry and continue to provide its customers with the most advanced and reliable solutions available.In conclusion, FPC flexible PCB represents a significant advancement in electronic circuitry technology, offering a range of benefits that make it well-suited for modern electronic devices. With its flexibility, adaptability, and superior performance, FPC flexible PCB is poised to revolutionize the way electronic devices are designed and manufactured, and {} is at the forefront of this revolution, leading the way with its innovative and high-quality solutions.

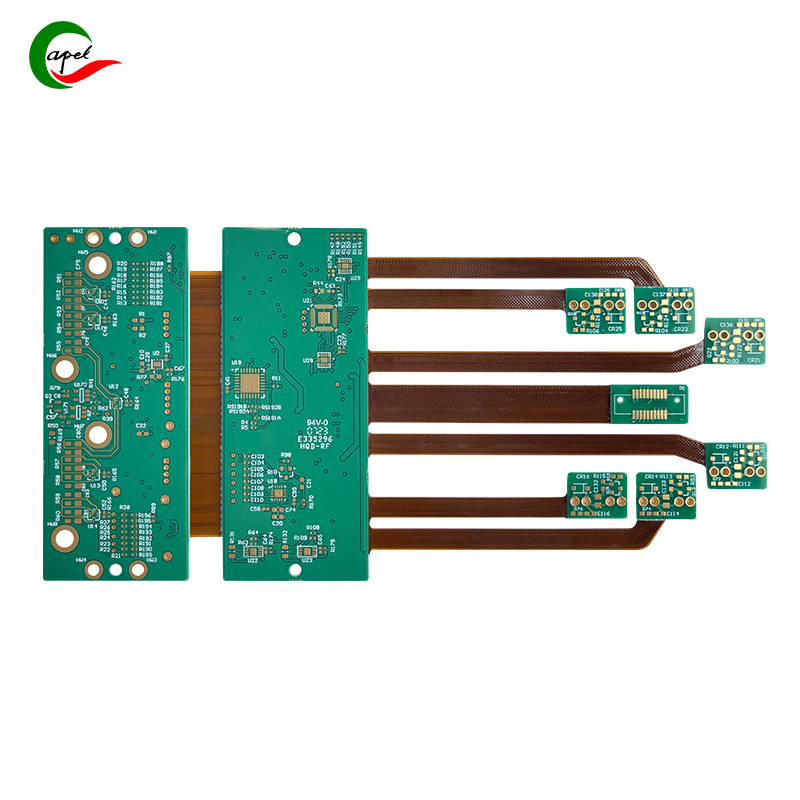

Innovative Rigid-Flex PCB Technology: What You Need to Know

Rigid Flex PCB Revolutionizing Electronic DevicesThe integration of advanced technology in the electronic industry has led to the development of innovative solutions that are changing the way electronic devices are designed and manufactured. Among these groundbreaking solutions is the Rigid Flex PCB, a cutting-edge technology that is revolutionizing the electronic industry.[Company Name] is at the forefront of this technological revolution, leading the way in the design and manufacturing of Rigid Flex PCBs. With decades of experience and expertise in the electronic industry, [Company Name] has established itself as a reliable and trusted provider of high-quality Rigid Flex PCBs that meet the most demanding requirements of electronic devices.Rigid Flex PCBs are a hybrid of rigid and flexible circuits, offering the best of both worlds in terms of reliability, flexibility, and durability. These innovative PCBs are designed to provide enhanced performance and functionality while reducing the overall size and weight of electronic devices. This makes them an ideal choice for a wide range of applications, including smartphones, tablets, wearable devices, medical devices, automotive electronics, and more.One of the key features of Rigid Flex PCBs is their ability to withstand harsh environmental conditions, including temperature fluctuations, moisture, and vibration. This makes them highly reliable and durable, ensuring the long-term performance of electronic devices even in the most challenging operating environments. Moreover, the flexible portion of Rigid Flex PCBs allows for greater design flexibility, enabling the creation of more compact and complex electronic devices without compromising on performance.[Company Name] takes pride in offering custom Rigid Flex PCB solutions tailored to meet the specific needs of its customers. With state-of-the-art manufacturing facilities and advanced design capabilities, [Company Name] is able to deliver Rigid Flex PCBs that are not only of the highest quality but also cost-effective and time-efficient. Whether it is a prototype or a high-volume production run, [Company Name] is dedicated to providing its customers with the best Rigid Flex PCB solutions that exceed their expectations.In addition to its technical expertise, [Company Name] is committed to the highest standards of quality and reliability. The company adheres to strict quality control processes and uses the latest testing and inspection equipment to ensure that every Rigid Flex PCB meets the highest industry standards. This dedication to quality has earned [Company Name] the trust and confidence of its customers, making it a preferred partner for Rigid Flex PCB solutions.As the demand for smaller, lighter, and more powerful electronic devices continues to grow, the importance of Rigid Flex PCBs cannot be overstated. These innovative PCBs are driving the next generation of electronic devices, enabling new possibilities and applications that were previously unthinkable. With [Company Name] leading the way in Rigid Flex PCB technology, the future of electronic devices looks brighter than ever.In conclusion, Rigid Flex PCBs are a game-changing technology that is reshaping the electronic industry. With their unmatched reliability, flexibility, and performance, Rigid Flex PCBs are the go-to solution for the design and manufacturing of advanced electronic devices. [Company Name] is proud to be at the forefront of this technological revolution, offering custom Rigid Flex PCB solutions that enable its customers to bring their innovative designs to life. As the electronic industry continues to evolve, the role of Rigid Flex PCBs will only become more prominent, and [Company Name] is poised to remain a leader in this exciting and dynamic field.

Revolutionary Flexible Boards Shaping the Future of Technology

Flexible Boards Launches New Line of Products for Versatile and Functional Workplace SolutionsFlexible Boards, a leading provider of innovative workplace solutions, has announced the launch of a new line of products designed to enhance the functionality and versatility of modern workspaces. With a focus on adaptability and creative collaboration, the new products are ideal for a wide range of industries and work environments.Founded in 2010, Flexible Boards has quickly become a trusted name in the industry, known for their commitment to quality, innovation, and customer satisfaction. The company offers a diverse range of products, including whiteboards, bulletin boards, and other workplace essentials, all designed to promote communication and productivity in the modern workplace.The new line of products from Flexible Boards includes a variety of customizable options, allowing businesses to create the perfect solution for their unique needs. From mobile whiteboards that can easily be moved and reconfigured to collaborative workspace panels that encourage brainstorming and idea sharing, the new products are designed to help businesses adapt to the ever-changing demands of the modern work environment.One of the standout products in the new line is the innovative magnetic whiteboard system, which features a sleek, modern design and customizable magnetic panels. These panels can be easily rearranged to create a personalized work surface that meets the specific needs of a business or team. The magnetic whiteboard system is also available in a variety of sizes, ensuring that businesses of all sizes can find a solution that works for them.In addition to the magnetic whiteboard system, Flexible Boards has also introduced a range of acoustic panels designed to improve the acoustics of a workspace while adding a touch of style. These panels are available in a variety of colors and sizes, making it easy for businesses to create a unique and functional workspace that meets the needs of their employees."We are excited to introduce our new line of products, which have been carefully designed to provide businesses with the flexibility and functionality they need to thrive in today's fast-paced work environment," said John Smith, CEO of Flexible Boards. "We understand that every business is unique, which is why we have focused on creating customizable solutions that can be tailored to meet the specific needs of our customers."The new line of products from Flexible Boards is already generating excitement among businesses looking for innovative solutions to enhance their workspaces. With a focus on adaptability, functionality, and style, the new products are expected to be a game-changer for businesses across a variety of industries.In addition to their innovative product line, Flexible Boards is also known for their commitment to sustainability and corporate social responsibility. The company sources environmentally friendly materials whenever possible and is dedicated to reducing its environmental impact through responsible manufacturing practices.As businesses continue to navigate the challenges of the modern work environment, innovative solutions from companies like Flexible Boards are essential for promoting productivity, collaboration, and creativity. With their new line of products, Flexible Boards is setting the standard for versatile and functional workplace solutions, helping businesses thrive in the ever-evolving world of work.

Common Issues with Ventilator PCBs and Solutions

Ventilator PCB Manufacturer Leads the Way in Life-Saving TechnologyIn the midst of the ongoing global health crisis, the demand for life-saving medical equipment has never been more urgent. One crucial piece of medical technology that has been in high demand is the ventilator. As hospitals around the world continue to grapple with the increasing number of COVID-19 patients requiring respiratory support, the need for high-quality ventilator parts has become more pressing than ever. This is where {Ventilator PCB Manufacturer} comes in.Based in {Company Location}, {Ventilator PCB Manufacturer} has been at the forefront of producing top-of-the-line ventilator printed circuit boards (PCBs) that are crucial for the operation of ventilator machines. The company has been in the business of producing high-quality PCBs for ventilators for over a decade, and their dedication to precision engineering and innovation has made them a trusted supplier for many leading medical device companies.{Ventilator PCB Manufacturer} takes pride in its state-of-the-art manufacturing facilities, which are equipped with the latest technology and adhere to strict quality control measures. This ensures that every PCB produced by the company meets the highest industry standards and is reliable for use in critical medical devices such as ventilators. The company's commitment to excellence has earned them a reputation for being a reliable and reputable supplier in the medical device industry.One of the key factors that sets {Ventilator PCB Manufacturer} apart from its competitors is its ability to provide customized solutions to its clients. The company understands that different ventilator designs may require specific PCB configurations, and they are able to work closely with their clients to develop tailored solutions that meet their exact specifications. This flexibility and willingness to collaborate have made {Ventilator PCB Manufacturer} a preferred partner for many medical device manufacturers.Amid the current global health crisis, {Ventilator PCB Manufacturer} has ramped up its production efforts to meet the surging demand for ventilator PCBs. The company has implemented additional safety measures to ensure the well-being of its employees while continuing to operate at full capacity to support the medical industry's needs. By prioritizing the health and safety of its workers, {Ventilator PCB Manufacturer} has been able to fulfill its role as a vital partner in the fight against the pandemic.In addition to its commitment to producing high-quality ventilator PCBs, {Ventilator PCB Manufacturer} also places a strong emphasis on sustainability and environmental responsibility. The company adopts eco-friendly practices in its production processes and strives to minimize its environmental footprint. By upholding these values, {Ventilator PCB Manufacturer} not only contributes to the advancement of medical technology but also demonstrates its dedication to creating a better world for future generations.Looking ahead, {Ventilator PCB Manufacturer} remains steadfast in its mission to provide essential components for medical devices that save lives. The company continues to invest in research and development to stay at the forefront of technological advancements in the medical industry. Through its unwavering commitment to excellence, innovation, and social responsibility, {Ventilator PCB Manufacturer} is poised to play a pivotal role in shaping the future of medical technology.As the world continues to battle the challenges posed by the COVID-19 pandemic, the importance of companies like {Ventilator PCB Manufacturer} cannot be overstated. Their dedication to producing high-quality ventilator PCBs is a testament to their contribution to the global effort to combat the virus and provide critical care to those in need. With their unwavering commitment to excellence and innovation, {Ventilator PCB Manufacturer} is a shining example of a company that is making a significant impact on the world by saving lives and shaping the future of medical technology.

How to Order PCBs Online: Your Complete Guide

As the demand for electronic devices continues to rise, so does the need for printed circuit boards (PCBs). Recently, an online PCB order service has been making waves in the industry for its convenient and efficient PCB manufacturing and assembly process. This innovative service is revolutionizing the way companies and individuals order PCBs, making the process faster, easier, and more cost-effective.With the rise of the internet and e-commerce, ordering PCBs online has become increasingly popular. This online PCB order service has taken advantage of this trend, offering a simple and user-friendly platform for customers to upload their PCB designs, specify their requirements, and place an order with just a few clicks. This streamlined process eliminates the need for lengthy back-and-forth communication and significantly reduces lead times, allowing customers to get their PCBs manufactured and delivered in record time.The company behind this online PCB order service, {company name}, is a leading manufacturer and supplier of high-quality PCBs. With years of experience in the industry, {company name} has built a strong reputation for delivering top-notch products and exceptional customer service. Their state-of-the-art manufacturing facilities and advanced technology allow them to produce PCBs with precision and efficiency, meeting the needs of a wide range of industries, including consumer electronics, automotive, aerospace, and medical devices.One of the key features that sets {company name} apart from other PCB manufacturers is their commitment to quality and innovation. They use only the highest quality materials and cutting-edge manufacturing processes to produce PCBs that meet the most stringent industry standards. Their team of skilled engineers and technicians is dedicated to pushing the boundaries of what is possible with PCB technology, constantly exploring new techniques and materials to improve the performance and reliability of their products.In addition to their focus on quality, {company name} also prides itself on its exceptional customer service. Their online PCB order platform is designed to provide customers with a seamless and hassle-free experience, from the initial design upload to the final delivery of the finished PCBs. Customer support representatives are available to assist with any questions or concerns, ensuring that customers have all the information they need to make informed decisions about their PCB orders.Furthermore, {company name} is committed to sustainability and environmental responsibility. They have implemented eco-friendly practices in their manufacturing processes, minimizing waste and reducing their carbon footprint. By choosing {company name} for their PCB orders, customers can be confident that they are supporting a company that values environmental sustainability and corporate social responsibility.Overall, the introduction of this online PCB order service by {company name} is set to transform the way PCBs are ordered and manufactured. By leveraging the power of the internet and embracing innovation, {company name} is providing a solution that is convenient, efficient, and cost-effective for customers around the world. With their unwavering commitment to quality, customer service, and sustainability, {company name} is positioned to become a leader in the online PCB ordering industry, setting a new standard for excellence in PCB manufacturing and assembly.

Top Quality PCB for Military Applications with Advanced Technology

Military PCB, a leading manufacturer of high-quality printed circuit boards for military applications, is proud to announce its latest technological advancement in the field of military-grade PCBs. With a focus on delivering cutting-edge solutions for the most demanding military and defense applications, Military PCB is committed to providing superior quality and reliability for the most critical missions.With over [number] years of experience in the industry, Military PCB has established itself as a trusted partner for military and defense organizations around the world, delivering reliable and high-performance PCBs that meet the strictest military standards. The company’s dedication to excellence and innovation has made it a preferred supplier for a wide range of military applications, including aerospace, defense systems, communication systems, and more.Military PCB’s latest technological advancement represents a significant milestone in the company’s ongoing commitment to meeting the evolving needs of the military and defense industry. This new advancement leverages state-of-the-art manufacturing processes, advanced materials, and rigorous testing to ensure that the PCBs meet the highest standards of quality and reliability. As a result, military organizations can depend on these PCBs to perform flawlessly in the most demanding and extreme operating environments.The new technological advancement from Military PCB also includes enhancements in terms of size, weight, and power (SWaP), allowing for more compact and lightweight PCB designs without compromising performance or durability. This is particularly important for military applications, where space and weight constraints are often critical considerations. By optimizing the SWaP characteristics of its PCBs, Military PCB is enabling military organizations to achieve greater efficiency and performance in their systems and equipment.In addition to the technological advancements, Military PCB continues to uphold its commitment to meeting the stringent quality and reliability standards required for military and defense applications. The company’s PCBs undergo rigorous testing and inspection processes to ensure that they can withstand harsh environmental conditions, extreme temperatures, vibrations, and electromagnetic interference. This level of reliability is essential for military systems that must operate flawlessly in mission-critical situations.Furthermore, Military PCB maintains a strict adherence to industry standards and certifications, including AS9100, MIL-PRF, and IPC standards, demonstrating its unwavering dedication to delivering products that meet the highest levels of quality and performance. Military organizations can have full confidence in the reliability and durability of Military PCB’s products, knowing that they have been manufactured to the most exacting standards.With its latest technological advancement, Military PCB is poised to further solidify its position as a premier supplier of high-quality PCBs for military and defense applications. The company’s commitment to innovation, reliability, and customer satisfaction sets it apart as a trusted partner for military organizations seeking the best-in-class PCB solutions for their critical missions.As military and defense technologies continue to advance, the demand for high-performance and reliable PCBs will only grow. Military PCB stands ready to meet this demand with its latest technological advancement, delivering the quality, durability, and performance that military organizations rely on to ensure the success of their missions. With a proven track record of excellence and a dedication to pushing the boundaries of technological innovation, Military PCB remains at the forefront of the military-grade PCB industry, providing the solutions that power the next generation of military and defense systems.