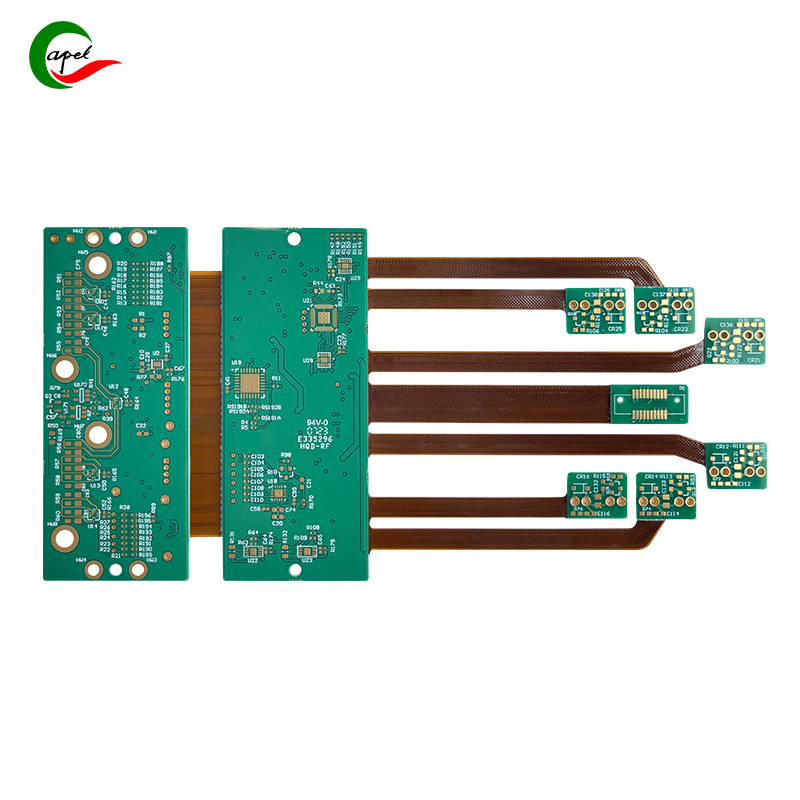

New Technology In Flexible Printed Circuits Unveiled in Latest Announcement

By:Admin

With over 20 years of experience in the industry, Advanced FPC has established itself as a trusted and reliable provider of high-quality flexible printed circuits. The company has garnered a reputation for delivering cutting-edge solutions to its customers, and this new product is no exception. Leveraging the latest advancements in technology and manufacturing processes, Advanced FPC has developed a product that is set to redefine the capabilities of flexible printed circuits.

The new product boasts a number of key features that set it apart from traditional flexible printed circuits. For starters, it offers a significantly higher level of flexibility and durability, making it ideal for use in a wide range of applications. This level of flexibility allows for more intricate and compact designs, enabling companies to create smaller and more lightweight electronic devices without sacrificing performance.

In addition to its superior flexibility, the new product also offers enhanced signal integrity and reliability. This is crucial for electronic devices, as it ensures that the circuits can consistently transmit signals without any degradation or interference. This level of performance is especially important for devices that operate in demanding environments or require high-speed data transmission.

Furthermore, the new product from Advanced FPC also offers a higher level of thermal performance, making it ideal for use in devices that generate a significant amount of heat. This is a key consideration for many electronic devices, as excessive heat can lead to performance issues and reduced lifespan. By leveraging advanced materials and design techniques, Advanced FPC has developed a product that can withstand higher operating temperatures, ensuring that it remains reliable and consistent in even the most challenging conditions.

One of the most significant advantages of the new product is its potential for cost savings. By offering a more efficient and streamlined manufacturing process, Advanced FPC has managed to reduce the overall production costs associated with flexible printed circuits. This, in turn, allows for more competitive pricing for their customers, making it an appealing option for companies looking to reduce their overall manufacturing costs.

"We are incredibly excited to introduce this groundbreaking new product to the market," said a spokesperson from Advanced FPC. "We believe that this product has the potential to revolutionize the electronics industry by offering companies a more efficient and cost-effective solution for their circuitry needs. We have worked tirelessly to leverage the latest advancements in technology and manufacturing processes to develop a product that truly pushes the boundaries of what is possible with flexible printed circuits."

The new product from Advanced FPC has already garnered significant interest from companies across a wide range of industries, including consumer electronics, medical devices, and automotive technology. Its superior performance, flexibility, and cost-saving potential make it an attractive option for companies looking to push the boundaries of what is possible with their electronic devices.

With its extensive experience and commitment to innovation, Advanced FPC is well-positioned to lead the way in the development of flexible printed circuits. The company's new product is a testament to its dedication to pushing the boundaries of what is possible within the industry, and it is expected to have a significant impact on the electronics industry as a whole.

As the electronics industry continues to evolve and demand for more advanced and efficient solutions grows, Advanced FPC is poised to remain at the forefront of innovation. With its new product set to revolutionize the market, the company is well-positioned to solidify its position as a leader in the development of flexible printed circuits.

Company News & Blog

How to Choose the Best PCB Board Maker for Your Needs

Pcb Board Maker (need remove brand name) is a leading company in the manufacturing of high-quality printed circuit boards. With years of experience in the industry, they have established themselves as a reliable and innovative partner for businesses in need of top-notch PCB solutions.Based in {location}, Pcb Board Maker (need remove brand name) prides itself on its state-of-the-art facilities and a team of skilled professionals who are dedicated to delivering excellence in every project they undertake. The company offers a wide range of services, including PCB design, prototyping, and mass production, catering to the diverse needs of their clients across various industries.One of the key strengths of Pcb Board Maker (need remove brand name) is its commitment to utilizing the latest technologies and production techniques. This allows them to stay ahead of the curve and provide their customers with cutting-edge solutions that meet the ever-evolving demands of the market. By maintaining a strong focus on research and development, the company continues to push the boundaries of what is possible in PCB manufacturing, ensuring that their clients receive products of the highest quality.In addition to their technical capabilities, Pcb Board Maker (need remove brand name) places a strong emphasis on customer satisfaction. They work closely with each client to understand their specific requirements and provide personalized solutions that are tailored to their needs. This customer-centric approach has earned them a reputation for reliability and responsiveness, further reinforcing their position as a leader in the industry.Furthermore, Pcb Board Maker (need remove brand name) is committed to upholding the highest standards of quality and adhering to industry best practices. They have implemented rigorous quality control measures throughout their production process, ensuring that every PCB meets the strictest performance and reliability standards. As a result, clients can trust in the durability and consistency of the products they receive from Pcb Board Maker (need remove brand name), giving them peace of mind in their own operations.Beyond their technical and operational excellence, Pcb Board Maker (need remove brand name) is also dedicated to sustainable and responsible business practices. They have implemented eco-friendly initiatives in their manufacturing processes, minimizing their environmental impact and contributing to a greener future. By prioritizing sustainability, the company aligns with the values of many of their clients who are also conscious of their environmental footprint.Looking ahead, Pcb Board Maker (need remove brand name) is poised to continue its trajectory of growth and success in the industry. They are constantly exploring new opportunities for innovation and expansion, seeking to further solidify their position as a trusted partner for businesses seeking top-tier PCB solutions. With a focus on excellence, customer satisfaction, and sustainability, Pcb Board Maker (need remove brand name) is well-equipped to meet the evolving needs of a dynamic market and remain a leader in the field.In conclusion, Pcb Board Maker (need remove brand name) stands as a testament to the heights that can be reached through a combination of expertise, dedication, and a commitment to exceeding expectations. As they continue to push boundaries and deliver exceptional products, they are sure to remain a driving force in the world of PCB manufacturing for years to come.

What You Need to Know About Flexible PCB Boards

Flexible PCB Board Technology Integration Leads to Improved Efficiency and ReliabilityIn the rapidly evolving world of electronic design and manufacturing, companies are constantly seeking innovative solutions to improve the performance and efficiency of their products. One such company that has successfully achieved this is {Company X}, a leading provider of advanced electronic components and solutions. Through the integration of flexible PCB board technology, {Company X} has been able to significantly enhance the reliability and flexibility of their products, setting new standards in the industry.Flexible PCB boards, also known as flex circuits, are a type of electronic circuitry that is manufactured using flexible plastic substrates. Unlike traditional rigid PCB boards, flex circuits offer a high degree of flexibility and can be bent, folded, or twisted to fit into tight spaces or conform to irregular shapes. This unique characteristic makes them ideal for applications where space is limited or where mechanical flexibility is required, such as in wearable devices, medical implants, automotive interiors, and aerospace systems.{Company X} has been at the forefront of integrating flexible PCB board technology into their product development process, recognizing the numerous advantages that it offers. By leveraging the expertise of their advanced R&D team and investing in state-of-the-art manufacturing capabilities, {Company X} has successfully developed a wide range of products that incorporate flexible PCB boards, ranging from consumer electronics to industrial control systems.One of the key benefits of using flexible PCB boards is the increased reliability they provide. Traditional rigid PCB boards are susceptible to mechanical stress and thermal expansion, leading to potential failure over time. In contrast, flex circuits are designed to withstand bending and flexing without compromising their electrical performance, making them highly durable and reliable. This improved resilience is particularly valuable in applications that are subject to constant movement or vibration, as it ensures consistent performance and longevity.Furthermore, the integration of flexible PCB board technology has enabled {Company X} to achieve new levels of miniaturization and space efficiency in their products. With the ability to bend and conform to non-linear shapes, flex circuits allow for the compact and efficient design of electronic systems, reducing overall size and weight while maintaining functionality. This has opened up new possibilities for {Company X} to develop cutting-edge products that are smaller, lighter, and more versatile, meeting the evolving needs of their customers across various industries.In addition to these technical advantages, {Company X} has also positioned itself as a leader in environmental sustainability through the use of flexible PCB boards. With their reduced material consumption and lighter weight, flex circuits contribute to a lower environmental impact compared to traditional rigid PCB boards, aligning with {Company X}'s commitment to sustainable practices and responsible manufacturing.Looking ahead, {Company X} is dedicated to further advancing the integration of flexible PCB board technology into their future product offerings. With ongoing research and development efforts focused on pushing the boundaries of design and innovation, {Company X} aims to continue setting new benchmarks for efficiency, reliability, and functionality in the electronic components industry. By staying at the forefront of technological advancements and embracing the potential of flexible PCB boards, {Company X} is poised to empower their customers with next-generation solutions that drive progress and success in the digital age.

The Top Rigid-Flex PCB Manufacturers You Need to Know About

Rigid Flex PCB Manufacturers Revolutionize the Electronics IndustryThe electronics industry is constantly evolving and demanding innovative solutions to meet the needs of various applications. One such innovation that is revolutionizing the industry is the development of rigid flex PCBs. Rigid flex PCBs are a combination of rigid and flexible PCBs, providing a more versatile and durable solution for electronic devices.As the demand for smaller, lighter, and more reliable electronic devices continues to grow, the need for rigid flex PCBs has become increasingly important. This has led to the emergence of several manufacturers in the industry, striving to meet the growing demand with high-quality and reliable solutions.One such manufacturer is {}, a leading provider of rigid flex PCBs. With years of expertise in the industry, they have established themselves as a trusted name in the market, offering innovative solutions to meet the needs of various industries.{} specializes in the design and manufacturing of rigid flex PCBs for a wide range of applications, including aerospace, medical devices, automotive, and consumer electronics. Their commitment to quality and innovation has made them a preferred choice for many leading companies in the electronics industry.The company's state-of-the-art manufacturing facilities and advanced technologies enable them to produce high-quality rigid flex PCBs that meet the highest industry standards. Their team of skilled engineers and technicians work closely with clients to understand their specific requirements and provide customized solutions to meet their needs.In addition to their manufacturing capabilities, {} also offers design and engineering support to help clients optimize their rigid flex PCB designs for maximum performance and reliability. Their dedication to providing comprehensive solutions has earned them a strong reputation in the industry.With the increasing demand for rigid flex PCBs, manufacturers like {} are playing a crucial role in driving the growth and innovation in the electronics industry. Their ability to deliver cutting-edge solutions that meet the evolving needs of the market has positioned them as a key player in the industry.In a statement, a spokesperson for {} commented, "We are committed to pushing the boundaries of innovation in the electronics industry. Our focus on quality, reliability, and customer satisfaction has allowed us to establish ourselves as a trusted partner for many leading companies. We continue to invest in research and development to stay ahead of the curve and deliver the best possible solutions to our clients."The demand for rigid flex PCBs is expected to continue to grow as the electronics industry evolves and new applications emerge. Manufacturers like {} are well-positioned to meet this demand with their advanced capabilities and commitment to innovation.As the industry continues to embrace the benefits of rigid flex PCBs, manufacturers will play a critical role in driving the adoption of this technology. With their expertise and resources, companies like {} are set to lead the way in shaping the future of the electronics industry.In conclusion, the emergence of rigid flex PCB manufacturers like {} is revolutionizing the electronics industry, providing innovative solutions to meet the evolving needs of the market. With their commitment to quality, reliability, and customer satisfaction, they are driving the growth and innovation in the industry, and are well-positioned to play a leading role in shaping the future of electronics.

The Latest Developments in the World of PCB Boards Unveiled - Stay Updated!

[Company Name] and PCB Board: Driving Growth and Innovation in Electronics Manufacturing[City, Date] - [Company Name], a leading player in the electronics manufacturing industry, is set to revolutionize the market with their state-of-the-art PCB (Printed Circuit Board) technology. Built on a foundation of innovation and expertise, [Company Name] is poised to create cutting-edge solutions for a variety of industries and applications.PCB boards are the backbone of electronic devices, providing the necessary connections and pathways for electrical signals to flow. With advancements in technology and increasing demand for smaller, faster, and more efficient electronics, PCBs have become a critical component for manufacturers around the world. [Company Name]'s commitment to excellence and continuous improvement has made them a key player in this ever-evolving landscape.At [Company Name], their PCB boards are developed using the latest manufacturing techniques and materials, ensuring high-quality, reliable performance. Whether it is a simple single-layer board or a complex multi-layer design, their team of experts can design and produce customized PCB solutions tailored to meet the specific needs of their clients. Their extensive range of capabilities allows them to serve a diverse customer base across industries such as consumer electronics, automotive, aerospace, medical, and telecommunications.With a keen focus on research and development, [Company Name] strives to stay at the forefront of technological advancements in PCB manufacturing. They collaborate with industry partners, academic institutions, and research organizations to push the boundaries of innovation. By investing in advanced machinery and equipment, [Company Name] delivers PCB boards that not only meet industry standards but also exceed customer expectations in terms of performance, durability, and reliability.In addition to their commitment to quality, [Company Name] places a strong emphasis on sustainability and environmentally friendly practices. They adhere to strict regulations and guidelines to reduce their carbon footprint, minimize waste generation, and promote sustainable sourcing and production processes. By leveraging eco-friendly materials and optimizing energy consumption, [Company Name] ensures that their PCB boards are not only technologically advanced but also environmentally responsible.The global electronics market is experiencing rapid growth, and [Company Name] is well-positioned to capitalize on these opportunities. Their ability to consistently deliver high-quality PCB boards has garnered them a reputation for reliability and customer satisfaction. In an industry where time to market is critical, [Company Name] stands out by providing efficient turnaround times without compromising on quality. Their just-in-time manufacturing approach and streamlined processes enable them to meet the demanding delivery schedules of their clients.Furthermore, [Company Name] offers comprehensive after-sales support, ensuring that customers receive prompt assistance whenever needed. Their dedicated customer service team is always available to address any queries or concerns, providing a personalized experience to each client.Looking ahead, [Company Name] is constantly exploring new avenues for growth and expansion. With emerging technologies such as IoT (Internet of Things), 5G, and autonomous vehicles creating huge demand for innovative electronic solutions, [Company Name] is investing in research and development to stay ahead of the curve. By leveraging their expertise and extending their range of capabilities, they aim to forge new partnerships and collaborations to drive advancements in the electronics manufacturing industry.In conclusion, [Company Name] is revolutionizing the electronics manufacturing market with their advanced PCB board technology. With a strong focus on innovation, sustainability, and customer satisfaction, they are well-positioned for success in an industry that demands excellence. As the global market continues to evolve, [Company Name] remains committed to driving growth and pushing the boundaries of what is possible in electronics manufacturing.

Advanced PCB Technology: NiPdAu vs Traditional Options

NiPdAu PCB: The Future of Advanced CircuitryIn today's fast-paced and technology-driven world, the demand for high-performance electronic devices continues to grow at an unprecedented rate. This has led to an increasing need for advanced printed circuit boards (PCBs) that can meet the demands of modern electronics. One company at the forefront of this cutting-edge technology is [Company Name], a leading manufacturer of electronic components and PCBs.At the heart of [Company Name]'s innovative PCB technology is the NiPdAu (nickel-palladium-gold) finish, a revolutionary solution that offers unparalleled performance and reliability. The NiPdAu finish is a triple-layer metal plating that provides superior protection against corrosion and oxidation, making it ideal for use in high-frequency and high-reliability applications. This advanced finish ensures that the PCBs can withstand the harshest operating conditions while maintaining optimal signal integrity and reliability.The NiPdAu finish also offers exceptional solderability and durability, making it the perfect choice for advanced electronic assemblies that require high-temperature processing and extreme environmental conditions. In addition, the gold layer provides excellent resistance to wear and tear, ensuring a longer lifespan for the PCBs and the electronic devices they power. Overall, the NiPdAu finish sets a new standard for PCB reliability and performance, making it an essential component in the advancement of electronic technology.One of the key advantages of [Company Name]'s NiPdAu PCBs is their compatibility with a wide range of electronic applications, including telecommunications, aerospace, medical devices, and automotive electronics. This versatility makes them an ideal choice for manufacturers looking to create highly reliable and high-performance electronic devices in a variety of industries. Furthermore, [Company Name] is committed to sustainable and environmentally friendly manufacturing practices, ensuring that their NiPdAu PCBs are produced in an eco-friendly manner while maintaining exceptional performance and reliability. This focus on sustainability and quality has earned [Company Name] a reputation as a trusted and reliable partner for electronic component manufacturing.In addition to its advanced PCB technology, [Company Name] offers a range of comprehensive services, including design support, prototyping, and full-scale production. This end-to-end approach allows customers to benefit from [Company Name]'s extensive expertise in electronic component manufacturing, ensuring that their PCBs meet the highest standards of quality and reliability.As the demand for high-performance electronic devices continues to grow, [Company Name]'s NiPdAu PCBs are poised to play a crucial role in shaping the future of advanced circuitry. With their superior performance, reliability, and compatibility with a wide range of electronic applications, NiPdAu PCBs are set to become the go-to solution for manufacturers looking to push the boundaries of electronic technology.In conclusion, [Company Name] is leading the way in the development of advanced NiPdAu PCB technology, offering a solution that meets the evolving demands of modern electronics. With their commitment to sustainability, quality, and customer satisfaction, [Company Name] is poised to revolutionize the electronic component industry and drive the advancement of electronic technology into the future.

Leading PCB Manufacturer in China: Your Top Choice for Quality and Reliability

Over the past decade, China has become a leading global manufacturing hub for a wide range of industries, and the printed circuit board (PCB) manufacturing sector is no exception. With a growing number of companies relying on electronic devices, the demand for high-quality PCBs has skyrocketed, leading to the rise of various PCB manufacturers in China, including the renowned company {}.Founded in {}, {} has established itself as a leading manufacturer of PCBs in China, with a strong focus on innovation, quality, and customer satisfaction. The company has a state-of-the-art manufacturing facility equipped with the latest technology and a highly skilled workforce that enables them to produce a wide range of PCBs for diverse applications.Recently, {} made headlines with the announcement of their latest technological advancements in PCB manufacturing. The company has invested heavily in research and development to enhance their production processes and improve the quality and performance of their PCBs. These advancements include the integration of advanced materials, improved designs, and increased production efficiency, allowing {} to meet the evolving needs of their customers and stay ahead of the competition.In addition to their technological advancements, {} has also taken significant steps to ensure that their manufacturing processes are environmentally friendly and sustainable. The company has implemented eco-friendly practices, such as recycling and waste reduction, in their operations to minimize their carbon footprint and contribute to a greener planet.One of the key factors that sets {} apart from other PCB manufacturers in China is their commitment to customer satisfaction. The company strives to provide tailored solutions to meet the specific requirements of their clients, whether they operate in the automotive, telecommunications, medical, or consumer electronics industries. {} works closely with their customers throughout the entire production process, from design to delivery, to ensure that the final product meets or exceeds their expectations.Furthermore, {} has a strict quality control system in place to guarantee the reliability and performance of their PCBs. Each product undergoes rigorous testing and inspection to ensure that it meets the highest industry standards. As a result, {} has earned a stellar reputation for delivering top-notch PCBs that are durable, efficient, and cost-effective.As the global demand for electronic devices continues to grow, the role of PCB manufacturers like {} becomes increasingly crucial. With their cutting-edge technology, commitment to sustainability, and dedication to customer satisfaction, {} is well-positioned to meet the needs of their clients and maintain their leading position in the competitive PCB manufacturing market.Looking ahead, {} is poised to expand their operations and strengthen their presence in both domestic and international markets. The company is committed to staying at the forefront of technological advancements in PCB manufacturing and contributing to the ongoing development of the electronics industry.In conclusion, the impressive advancements made by {} in PCB manufacturing are a testament to their dedication to excellence and innovation. As China continues to play a pivotal role in the global manufacturing landscape, companies like {} are setting new standards for quality and reliability, driving the industry forward and meeting the ever-growing demand for high-quality PCBs.

Innovations in Double-Side Rigid-Flex PCB Technology

The demand for Double-Side Rigid-Flex PCBs is on the rise due to their numerous advantages in electronic applications. These innovative circuit boards are becoming increasingly popular in industries such as aerospace, medical devices, automotive, and consumer electronics. One company that has been at the forefront of producing high-quality Double-Side Rigid-Flex PCBs is {Company}.{Company} is a leading manufacturer of advanced electronic components, specializing in the development and production of Double-Side Rigid-Flex PCBs. The company has earned a reputation for delivering reliable and cutting-edge solutions to meet the evolving needs of the electronics industry. With a strong focus on research and development, {Company} has been able to stay ahead of the curve and provide its customers with state-of-the-art products that exceed industry standards.Double-Side Rigid-Flex PCBs offer a unique combination of flexibility and rigidity, making them suitable for a wide range of applications. These circuit boards are designed to withstand demanding environmental conditions, making them perfect for use in harsh operating environments. The flexibility of Rigid-Flex PCBs allows for greater design freedom, enabling engineers to create smaller, lighter, and more compact electronic devices. By eliminating the need for multiple interconnects, Double-Side Rigid-Flex PCBs also reduce overall system complexity and improve reliability.{Company} prides itself on its commitment to quality and innovation. The company's state-of-the-art manufacturing facilities and rigorous quality control processes ensure that every Double-Side Rigid-Flex PCB that leaves its factory meets the highest standards of performance and reliability. {Company} also offers customized solutions to meet the specific needs of its customers, working closely with them to develop tailored Double-Side Rigid-Flex PCBs for their unique applications.In addition to its focus on product quality, {Company} is also dedicated to sustainability and environmental responsibility. The company employs eco-friendly manufacturing practices and utilizes materials that are compliant with industry regulations. By prioritizing sustainability, {Company} aims to minimize its environmental impact and contribute to a cleaner, greener future.With a team of experienced and skilled professionals, {Company} is uniquely positioned to provide comprehensive support to its customers, from initial design concept to full-scale production. The company's engineers work closely with customers to understand their specific requirements, providing expert guidance and technical expertise to ensure the successful implementation of Double-Side Rigid-Flex PCBs in their electronic applications.The demand for Double-Side Rigid-Flex PCBs is expected to continue growing as electronic devices become more complex and compact. {Company} is well-prepared to meet this increasing demand, leveraging its expertise and technological capabilities to deliver advanced solutions to its customers. By staying at the forefront of technological advancements and maintaining a strong commitment to quality and innovation, {Company} is poised to remain a leader in the Double-Side Rigid-Flex PCB industry.The future looks bright for {Company} as it continues to push the boundaries of what is possible in the field of Double-Side Rigid-Flex PCBs. With its unwavering dedication to excellence and customer satisfaction, the company is well-positioned to drive the advancement of electronic technology and make a lasting impact on the industry. It is clear that {Company} is a force to be reckoned with in the world of Double-Side Rigid-Flex PCB manufacturing, and its future is set to be a bright and prosperous one.

Discover the Benefits of High-Quality PCBs for Your Electronics Projects

High-Quality PCBs: A Game-Changer in Electronic ManufacturingIn today’s fast-paced and technologically advanced world, electronic devices have become an integral part of our daily lives. From smartphones to household appliances, the demand for high-quality printed circuit boards (PCBs) has never been higher. As a leading player in the electronic manufacturing industry, {Company Name} is setting new standards with its innovative and cutting-edge PCB solutions.With over [number of years] years of experience in the industry, {Company Name} has established itself as a trusted and reliable partner for businesses looking to source top-of-the-line PCBs. The company’s commitment to quality, precision, and technological innovation has earned it a stellar reputation among its peers and clients. From prototyping to mass production, {Company Name} offers a comprehensive range of PCB services tailored to meet the specific needs of its diverse clientele.What sets {Company Name} apart from its competitors is its relentless pursuit of excellence in every aspect of PCB manufacturing. The company’s state-of-the-art facilities are equipped with the latest machinery and technology, allowing for the production of high-density, high-precision PCBs that meet the strictest quality standards. {Company Name} also boasts a team of highly skilled engineers and technicians who are dedicated to ensuring that every PCB that leaves their facility is of the highest quality.One of the key factors that contribute to the superior quality of {Company Name}’s PCBs is its unwavering commitment to using only the best materials and components. Whether it’s sourcing raw materials or selecting the most suitable components for a specific application, the company’s strict quality control measures guarantee that every PCB meets or exceeds the industry’s standards.Moreover, {Company Name} takes pride in its ability to provide customized solutions to its clients. Whether a client requires a specific type of PCB for a specialized application or needs assistance with designing a custom layout, {Company Name}’s team of experts is always ready to offer their expertise and guidance. This flexibility and willingness to go the extra mile for its clients have positioned {Company Name} as a preferred partner for businesses looking to push the boundaries of innovation.Another critical aspect of {Company Name}’s success is its unwavering focus on research and development. Recognizing the ever-evolving nature of the electronic industry, the company is continuously investing in new technologies and processes to ensure that its PCBs remain at the forefront of innovation. This commitment to staying ahead of the curve has allowed {Company Name} to consistently introduce new and improved PCB solutions that not only meet but exceed the expectations of its clients.Furthermore, {Company Name} takes its environmental responsibilities seriously. The company has implemented eco-friendly practices throughout its manufacturing process, minimizing its carbon footprint and ensuring that its operations are sustainable. By using environmentally friendly materials and adhering to rigorous recycling and waste management practices, {Company Name} is doing its part to contribute to a cleaner and greener future.In conclusion, {Company Name}’s dedication to excellence, innovation, and sustainability has positioned it as a leader in the electronic manufacturing industry. The company’s high-quality PCBs are a testament to its unwavering commitment to meeting the needs of its clients while pushing the boundaries of what is possible in electronic manufacturing. As the demand for advanced electronic devices continues to grow, {Company Name} is poised to remain at the forefront, delivering top-of-the-line PCB solutions that are truly a game-changer in the industry.

Essential Manufacturing: Advancements in PCB Technology for Medical Applications

Medical PCBs Play a Vital Role in Advancing Healthcare TechnologiesAs the field of healthcare continuously evolves, medical printed circuit boards (PCBs) have emerged as essential components in a variety of cutting-edge medical devices. These intricate circuit boards have revolutionized the way medical equipment operates, enabling improved diagnostics, treatment, and patient care. With their ability to provide precise and reliable data, medical PCBs have become indispensable in the medical industry.Medical PCBs are specifically designed to meet the stringent requirements of medical devices. They are built with advanced technology, ensuring optimum performance, durability, and reliability. These PCBs are used in a wide range of medical equipment, including diagnostic imaging devices, patient monitoring systems, surgical instruments, implantable devices, and laboratory equipment.One of the key advantages of medical PCBs is their ability to handle complex electronic designs. As medical devices become more sophisticated, the need for compact and densely packed circuitry has increased. Medical PCBs accommodate these intricate designs by utilizing advanced manufacturing techniques such as high-density interconnects (HDI) and multilayer technology. This ensures that medical devices have a smaller form factor without compromising on functionality, enabling healthcare providers to offer more efficient and accurate healthcare services.Moreover, medical PCBs are built to withstand various environmental conditions, including temperature, humidity, and vibrations. This is particularly crucial in medical applications where equipment may be subjected to rigorous sterilization processes or transported frequently. High-quality medical PCBs are designed to withstand these challenges, guaranteeing consistent performance and avoiding costly downtime in healthcare facilities.Additionally, medical PCBs play a crucial role in maintaining patient safety. They are designed with several safety features, including insulation barriers and fire-resistant materials, to prevent any electrical hazards. These safety measures ensure that medical devices operate reliably and do not pose any risk to patients or healthcare professionals. The incorporation of fail-safe systems and redundant circuitry further enhances the reliability of medical devices, reducing the chances of malfunctions during critical procedures.In recent years, medical PCB manufacturers have also focused on developing new technologies to address emerging healthcare demands. For instance, the integration of wireless communication capabilities in medical PCBs has facilitated the development of telemedicine and remote patient monitoring systems. These advancements allow patients to receive healthcare services remotely, reducing the burden on clinics and hospitals while providing patients with convenient access to medical expertise.Furthermore, the continuous advancement of medical PCB technology has paved the way for the development of advanced imaging devices, such as magnetic resonance imaging (MRI) and computed tomography (CT) scanners. Medical PCBs enable high-speed data transmission, enabling healthcare professionals to obtain detailed and accurate images for diagnostics. This has significantly improved the efficiency and accuracy of medical imaging, leading to better patient outcomes.In conclusion, medical PCBs have become indispensable components in the healthcare industry. Their ability to handle complex designs, withstand rigorous environments, ensure patient safety, and support emerging healthcare technologies has revolutionized medical devices. As the field of healthcare continues to evolve, medical PCB manufacturers will play a vital role in driving innovation and delivering advanced solutions that improve patient care and outcomes.

Top Pcb Manufacturing Services in China - A Complete Guide

China is known for its dominance in the manufacturing industry, and this holds true for the production of printed circuit boards (PCBs) as well. PCBs are a crucial component in the electronic devices that power our modern lives, and the demand for high-quality PCBs is at an all-time high. In the heart of China's manufacturing hub, {} has emerged as a leading manufacturer of PCBs, providing top-notch products for a wide range of industries.Established in the early 2000s, {} has grown to become a key player in the PCB manufacturing industry. With a state-of-the-art production facility and a team of highly skilled engineers and technicians, the company is able to deliver superior quality PCBs to meet the specific requirements of its clients. It has also invested heavily in research and development to stay ahead of the curve in terms of technology and innovation, ensuring that its products are always at the cutting edge of the industry.The company's commitment to quality and customer satisfaction has earned it a stellar reputation in the industry. It is able to offer a comprehensive range of PCB products, including single-sided, double-sided, and multi-layer boards, as well as flexible and rigid-flex PCBs. This wide range of capabilities allows {} to serve clients across various sectors, including telecommunications, automotive, medical devices, consumer electronics, and more.One of the key factors that sets {} apart from its competitors is its ability to provide customized solutions to meet the unique needs of its clients. The company works closely with each customer to understand their specific requirements and to develop tailored PCB solutions that deliver optimal performance and reliability. This level of customization and attention to detail has helped {} build long-term partnerships with many of its clients, who rely on the company to deliver high-quality PCBs that power their products.In addition to its focus on quality and customization, {} is also committed to sustainability and environmental responsibility in its manufacturing processes. The company adheres to strict environmental standards and practices, ensuring that its operations have minimal impact on the environment. {} strives to minimize waste and energy consumption, and it prioritizes the use of environmentally friendly materials and processes in its production.As a result of its dedication to excellence and sustainability, {}'s PCBs have gained recognition not only in China but also in the global market. The company exports its products to clients around the world, and its reputation for reliability and quality has helped it establish a strong presence in international markets.Looking ahead, {} is poised for further growth and success in the PCB manufacturing industry. With a strong foundation of expertise, a commitment to innovation, and a focus on customer satisfaction, the company is well-positioned to continue meeting the evolving needs of its clients and to expand its reach in the global market. As the demand for high-quality PCBs continues to rise, {} is ready to seize new opportunities and to uphold its position as a leader in the industry.In conclusion, {} represents the pinnacle of PCB manufacturing in China, offering top-notch products, innovative solutions, and a commitment to sustainability. With a track record of excellence and a dedication to customer satisfaction, the company is well-equipped to meet the growing demand for high-quality PCBs in the global market. As technology continues to advance, {} remains at the forefront of the industry, driving innovation and delivering superior PCB solutions for a wide range of applications.