Top Flex Circuits Manufacturers: Offering High-Quality Solutions for Your Needs

By:Admin

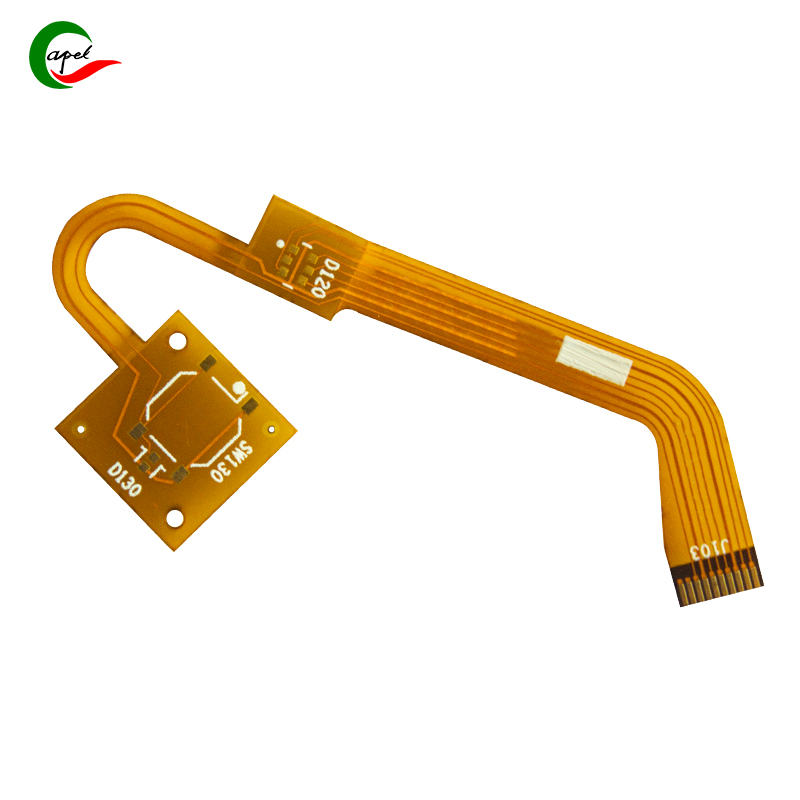

The company has been a pioneer in the development and production of flexible printed circuits for over (number) years, and their expertise in this field is unmatched. Their flexible circuits are used in a variety of industries, including automotive, medical, aerospace, and consumer electronics. These circuits are designed to be lightweight, compact, and highly reliable, making them an ideal choice for applications where traditional rigid PCBs are not suitable.

One of the key advancements that (brand name) has announced is the development of new materials that will improve the flexibility and durability of their circuits. These materials have been carefully chosen and tested to ensure that they meet the highest standards for performance and reliability. This will allow (brand name) to expand their product line and offer even more options for their customers.

In addition to these new materials, (brand name) has also made significant improvements to their manufacturing processes. These improvements will result in faster lead times and reduced costs, making their products even more competitive in the market. They have also invested in state-of-the-art equipment and technology to further enhance the quality and precision of their flexible circuits.

Furthermore, (brand name) has expanded their capabilities to offer custom solutions for their customers. They understand that every application is unique, and their team of experienced engineers is ready to work closely with customers to design and produce custom flexible circuits that meet their specific needs. This level of customization sets (brand name) apart from other manufacturers and demonstrates their commitment to delivering exceptional products and service.

To support these advancements, (brand name) has also invested in training and development for their employees. They believe that their team is their greatest asset, and by providing ongoing training and support, they can ensure that their products meet the highest standards of quality and reliability. This investment in their workforce will further strengthen (brand name)'s position as a leading provider of flexible printed circuits.

In light of these advancements, (brand name) is confident that they will continue to meet the evolving needs of their customers and maintain their position as an industry leader. They are excited to bring these new innovations to market and are eager to see the impact that these advancements will have on their customers' applications.

As (brand name) looks to the future, they remain committed to pushing the boundaries of what is possible with flexible printed circuits. They are dedicated to staying at the forefront of technological advancements and are constantly exploring new opportunities to improve their products and services. By doing so, (brand name) is poised to continue driving innovation in the industry and providing their customers with the best possible solutions for their flexible circuit needs.

Company News & Blog

High-Quality Quick Turn Flexible Circuits for your Electronic Devices

Quick Turn Flex Circuits revolutionizes the electronics industry with its innovative flexible circuit solutions. As a leading provider of flexible circuitry, the company specializes in delivering high-quality, quick-turn solutions to meet the ever-evolving demands of the market.With over 20 years of experience in the industry, Quick Turn Flex Circuits has established itself as a trusted partner for businesses seeking reliable and efficient flexible circuit solutions. The company's state-of-the-art manufacturing facilities and team of highly skilled professionals enable them to deliver top-notch products that meet the most stringent quality and performance standards.One of the company's key strengths lies in its ability to provide quick-turn solutions. In today's fast-paced market, businesses often need to bring their products to market quickly in order to stay ahead of the competition. Quick Turn Flex Circuits understands this need and has developed streamlined processes to ensure rapid turnaround times without compromising on quality.The company's flexible circuit solutions are versatile and can be tailored to meet a wide range of applications. From consumer electronics to medical devices, automotive systems, and industrial equipment, Quick Turn Flex Circuits has the expertise to deliver custom solutions that cater to the unique requirements of each industry.Quick Turn Flex Circuits' commitment to innovation and continuous improvement is evident in its investment in cutting-edge technology and rigorous quality control processes. The company's manufacturing facilities are equipped with the latest equipment and tools to ensure precision and consistency in every product they produce. Additionally, their team of engineers and technicians undergo regular training to stay updated with the latest industry trends and best practices.The company's dedication to quality is further underscored by its adherence to industry standards and certifications. Quick Turn Flex Circuits is ISO 9001 and UL certified, demonstrating their commitment to delivering products that adhere to the highest standards of quality and safety.Quick Turn Flex Circuits' commitment to sustainability and environmental responsibility is another key aspect of its corporate identity. The company prioritizes sustainable manufacturing practices and continually seeks ways to reduce its environmental footprint. This includes the use of eco-friendly materials and processes, as well as waste reduction and recycling initiatives.Furthermore, Quick Turn Flex Circuits maintains a strong focus on customer satisfaction. The company's team of dedicated professionals works closely with clients to understand their specific needs and provide personalized solutions that exceed expectations. Whether it's a complex design challenge or a tight deadline, Quick Turn Flex Circuits is known for its responsiveness and ability to deliver results that meet and exceed customer requirements.The company's success and reputation are further reinforced by its extensive track record of successful projects and satisfied customers. Quick Turn Flex Circuits has worked with a diverse portfolio of clients, ranging from startups to multinational corporations, and has consistently delivered exceptional results across various industries.In conclusion, Quick Turn Flex Circuits stands out as a leading provider of flexible circuit solutions, offering quick-turn capabilities, cutting-edge technology, rigorous quality control, environmental responsibility, and a strong focus on customer satisfaction. With a proven track record of success and a commitment to excellence, the company continues to set the benchmark for innovation and reliability in the electronics industry.

FPC PCB: Breaking News Reveals Latest Developments in Printed Circuit Boards

Title: Cutting-Edge PCB Manufacturer Introduces FPC Innovation to Revolutionize Electronics IndustryIntroduction:In a game-changing move for the electronics industry, a leading PCB manufacturer is set to unleash an innovation that could revolutionize the way electronic devices are designed and manufactured. Renowned for their exceptional expertise and cutting-edge technology, this company is set to unveil their Flexible Printed Circuit (FPC) solution. With its immense potential to enhance device performance and reduce manufacturing complexities, FPC is poised to become the new industry standard.Section 1: The Rising Demand for Advanced PCB SolutionsIn an age of rapidly advancing technologies, the demand for more efficient and reliable electronic devices is reaching unprecedented levels. The intricate interconnections within electronic components necessitate highly reliable and customizable PCB solutions. With the global PCB market expected to surpass $85 billion by 2025, manufacturers are under immense pressure to deliver innovative solutions that can cater to ever-evolving consumer demands.Section 2: Introducing FPC - The Future of Flexible CircuitryRecognizing the need for next-generation PCB solutions, {Company name} has unveiled its highly anticipated FPC technology. FPC, short for Flexible Printed Circuit, is a groundbreaking advancement that replaces the rigid FR4 substrates with flexible polymer materials. This enables electronic designers and manufacturers to create intricate and complex circuit layouts that were previously impossible with traditional PCB designs.Section 3: Advantages of FPC Over Traditional PCBsOne of the key advantages of FPC lies in its exceptional flexibility. By eliminating the rigidity of conventional PCBs, FPC allows for unprecedented design freedom, enabling circuit boards to be bent, shaped, and fitted into spaces that were previously inaccessible. This opens up new avenues for designers to create sleeker, more compact electronic devices without compromising functionality.Additionally, FPC offers remarkable weight reduction compared to traditional PCBs, making it highly suitable for portable devices like smartphones and wearables. The increased flexibility also results in improved shock and vibration resistance, enhancing the overall durability of electronic products.Section 4: Enhanced Performance and ReliabilityFPC's flexible design minimizes the issues associated with stress-induced failures that often occur in rigid PCBs due to environmental factors or mechanical stress. The dynamic nature of FPC ensures better signal integrity, reduced cross-talk, and improved impedance control, leading to enhanced overall performance and reliability of electronic devices.Section 5: Streamlined Manufacturing ProcessTraditionally, PCB manufacturing involves multiple steps, including drilling, punching, and assembly. FPC technology simplifies this process significantly by eliminating the need for drilling and reducing the number of components required. This leads to shorter production cycles and lowers the overall manufacturing costs, making FPC an attractive choice for both small-scale and high-volume production.Section 6: FPC's Potential ApplicationsThe versatility of FPC technology opens up a myriad of potential applications across various industries. From consumer electronics like smartphones, tablets, and wearable devices to automotive components, medical devices, aerospace systems, and more, the future of FPC is bright and far-reaching. Its potential to transform the electronics industry will undoubtedly spur innovation and facilitate the development of advanced and groundbreaking products.Section 7: ConclusionIn conclusion, the introduction of FPC technology by {Company name} marks a significant milestone in the electronics industry. With its remarkable advantages over traditional PCBs, FPC is set to revolutionize the design and manufacturing processes while ensuring superior performance, reliability, and cost-efficiency. The opportunities offered by FPC are limitless, promising a future of more compact, lighter, and smarter electronic devices that will continue to shape our digital world.

The Latest Innovation in PCB Board Technology: What You Need to Know

[Company Name] Introduces Next-Generation PCB Board for Enhanced Performance and Reliability[City, Date] - [Company Name], a leading provider of innovative electronic solutions, is excited to announce the launch of its latest PCB board, designed to offer enhanced performance, reliability, and efficiency for a wide range of applications.The new PCB board, developed by [Company Name]'s team of experienced engineers and designers, features cutting-edge technology and advanced materials to meet the growing demands of the electronics industry. With a focus on delivering high-quality, cost-effective solutions, [Company Name] is dedicated to staying at the forefront of technological advancements to provide its customers with the best products and services.Key features of [Company Name]'s new PCB board include:1. High-Speed Performance: The PCB board is engineered to support high-speed data transmission, making it ideal for applications that require rapid and efficient communication between components.2. Enhanced Reliability: With a focus on durability and longevity, the PCB board is built to withstand harsh environmental conditions and maintain stable performance over time.3. Advanced Materials: The use of advanced materials and manufacturing processes ensures that the PCB board meets industry standards for quality and performance.4. Customization Options: [Company Name] offers customization options to meet the specific requirements of its customers, allowing for tailored solutions that address unique challenges and demands."We are thrilled to introduce our latest PCB board to the market," said [Spokesperson] of [Company Name]. "This new product exemplifies our commitment to innovation and excellence, and we are confident that it will provide our customers with the performance and reliability they expect from [Company Name]."[Company Name] has a proven track record of delivering high-quality electronic solutions to a diverse range of industries, including telecommunications, automotive, consumer electronics, and more. With extensive experience and expertise in the field, [Company Name] has established itself as a trusted partner for companies seeking reliable and innovative electronic components and solutions.In addition to its new PCB board, [Company Name] offers a comprehensive range of electronic products and services, including design and engineering, manufacturing, testing, and support. The company's dedication to customer satisfaction and continuous improvement is evident in its commitment to delivering superior products and exceeding customer expectations.To learn more about [Company Name] and its new PCB board, visit [company website] or contact [Company Name] directly for inquiries and orders.About [Company Name]:[Company Name] is a leading provider of innovative electronic solutions, offering a comprehensive range of products and services to meet the diverse needs of the electronics industry. With a focus on quality, reliability, and customer satisfaction, [Company Name] is dedicated to delivering cutting-edge solutions that exceed industry standards and expectations.

Essential Guide to Printed Wiring Board Technology and Manufacturing

Printed Wiring Board Market Size, Share, Growth | Industry Report 2021-2026Printed Wiring Boards (PWBs), also known as printed circuit boards, are essential components in various electronic devices, including computers, smartphones, and medical equipment. The global Printed Wiring Board market is projected to experience substantial growth in the coming years, driven by the increasing demand for electronic products across industries such as automotive, consumer electronics, and telecommunications.The market size for Printed Wiring Boards was valued at USD 67.2 billion in 2020 and is expected to reach USD 85.6 billion by 2026, growing at a CAGR of 4.2% during the forecast period.Key players in the Printed Wiring Board market include {Company Name}, a leading manufacturer of high-quality PWBs for a wide range of applications. {Company Name} has established a strong foothold in the market due to its cutting-edge technological capabilities, commitment to quality, and extensive industry experience.Founded in {year}, {Company Name} has consistently delivered innovative PWB solutions to meet the evolving needs of its customers. The company’s state-of-the-art manufacturing facilities and stringent quality control processes ensure that its products adhere to the highest industry standards.{Company Name} offers a comprehensive range of Printed Wiring Boards, including single-sided, double-sided, and multi-layer boards, catering to diverse requirements across industries. With a focus on research and development, the company continuously strives to enhance the performance and functionality of its PWBs to meet the demands of advanced electronic devices and systems.In addition to its extensive product portfolio, {Company Name} places a strong emphasis on sustainability and environmental responsibility. The company adheres to eco-friendly manufacturing processes and materials, ensuring that its operations have minimal impact on the environment. Furthermore, {Company Name} actively invests in initiatives to reduce waste generation and promote recycling within its facilities.As a global leader in the Printed Wiring Board market, {Company Name} serves a wide customer base comprising electronics manufacturers, OEMs, and electronics component distributors. The company’s commitment to customer satisfaction, coupled with its efficient supply chain management, has enabled it to build strong and lasting partnerships with clients worldwide.{Company Name}’s approach to innovation and customer-centric solutions has positioned it as a trusted partner for companies seeking reliable and high-quality Printed Wiring Boards. The company’s dedication to continuous improvement and excellence has won it numerous accolades and recognitions within the industry.Looking ahead, {Company Name} remains focused on expanding its global presence and strengthening its position in the Printed Wiring Board market. By leveraging its expertise, technological advancements, and strategic partnerships, the company aims to capitalize on emerging opportunities and reinforce its status as a leading PWB manufacturer.In conclusion, the global Printed Wiring Board market is poised for substantial growth, driven by the increasing demand for electronic devices and advancements in technology. {Company Name}, with its unwavering commitment to quality, innovation, and sustainability, is well-positioned to capitalize on this growth and continue to play a pivotal role in shaping the future of the Printed Wiring Board industry.

Top 10 Virtual Reality Circuit Boards for Enhanced Gaming Experience

VR Circuit Boards, a leading provider of high-quality electronic circuit boards, has been making waves in the tech industry with its innovative products. The company prides itself on its ability to consistently deliver cutting-edge solutions that meet the needs of its customers and push the boundaries of what is possible in the world of electronics.Founded in 2005, VR Circuit Boards has quickly become a trusted name in the industry. The company's success can be attributed to its commitment to quality, innovation, and customer satisfaction. With a team of highly skilled engineers and technicians, VR Circuit Boards is able to design and produce circuit boards that are at the forefront of technological advancement.One of the key products that VR Circuit Boards has become known for is its virtual reality (VR) circuit boards. These circuit boards are specially designed to power the immersive and interactive experiences that VR technologies offer. VR Circuit Boards understands the unique requirements of VR devices and has developed a range of circuit boards that are optimized for this purpose.The VR circuit boards produced by VR Circuit Boards are renowned for their reliability, performance, and efficiency. They are designed to deliver smooth and responsive performance, ensuring that users can fully immerse themselves in the virtual worlds they explore. These circuit boards are also built to handle the high demands of VR applications, providing the necessary processing power and connectivity to deliver a seamless experience.In addition to their performance, the VR circuit boards from VR Circuit Boards are also recognized for their high-quality construction. The company places a strong emphasis on rigorous quality control and testing, ensuring that each circuit board meets the highest standards of reliability and durability. This commitment to excellence has earned VR Circuit Boards a reputation for producing some of the best VR circuit boards in the industry.Furthermore, VR Circuit Boards is dedicated to staying ahead of the curve when it comes to technological advancements. The company continuously invests in research and development, striving to develop new and improved circuit board solutions to meet the evolving needs of the industry. Whether it's enhancing performance, increasing energy efficiency, or adding new features, VR Circuit Boards is always looking for ways to push the boundaries of what is possible with electronic circuit boards.Alongside its dedication to innovation, VR Circuit Boards is also known for its exceptional customer service and support. The company works closely with its clients to understand their specific needs and requirements, ensuring that it delivers customized solutions that fully meet their expectations. This personalized approach has allowed VR Circuit Boards to build long-lasting relationships with its customers, who have come to rely on the company for their electronic circuit board needs.With its impressive track record and unwavering commitment to excellence, it's no wonder that VR Circuit Boards has become a leading force in the industry. The company's VR circuit boards are highly sought after by manufacturers, developers, and enthusiasts alike, who recognize the value of the high-quality solutions that VR Circuit Boards provides. As VR technologies continue to advance, VR Circuit Boards remains at the forefront, driving innovation and shaping the future of virtual reality experiences.

Innovations in Double-Side Rigid-Flex PCB Technology

The demand for Double-Side Rigid-Flex PCBs is on the rise due to their numerous advantages in electronic applications. These innovative circuit boards are becoming increasingly popular in industries such as aerospace, medical devices, automotive, and consumer electronics. One company that has been at the forefront of producing high-quality Double-Side Rigid-Flex PCBs is {Company}.{Company} is a leading manufacturer of advanced electronic components, specializing in the development and production of Double-Side Rigid-Flex PCBs. The company has earned a reputation for delivering reliable and cutting-edge solutions to meet the evolving needs of the electronics industry. With a strong focus on research and development, {Company} has been able to stay ahead of the curve and provide its customers with state-of-the-art products that exceed industry standards.Double-Side Rigid-Flex PCBs offer a unique combination of flexibility and rigidity, making them suitable for a wide range of applications. These circuit boards are designed to withstand demanding environmental conditions, making them perfect for use in harsh operating environments. The flexibility of Rigid-Flex PCBs allows for greater design freedom, enabling engineers to create smaller, lighter, and more compact electronic devices. By eliminating the need for multiple interconnects, Double-Side Rigid-Flex PCBs also reduce overall system complexity and improve reliability.{Company} prides itself on its commitment to quality and innovation. The company's state-of-the-art manufacturing facilities and rigorous quality control processes ensure that every Double-Side Rigid-Flex PCB that leaves its factory meets the highest standards of performance and reliability. {Company} also offers customized solutions to meet the specific needs of its customers, working closely with them to develop tailored Double-Side Rigid-Flex PCBs for their unique applications.In addition to its focus on product quality, {Company} is also dedicated to sustainability and environmental responsibility. The company employs eco-friendly manufacturing practices and utilizes materials that are compliant with industry regulations. By prioritizing sustainability, {Company} aims to minimize its environmental impact and contribute to a cleaner, greener future.With a team of experienced and skilled professionals, {Company} is uniquely positioned to provide comprehensive support to its customers, from initial design concept to full-scale production. The company's engineers work closely with customers to understand their specific requirements, providing expert guidance and technical expertise to ensure the successful implementation of Double-Side Rigid-Flex PCBs in their electronic applications.The demand for Double-Side Rigid-Flex PCBs is expected to continue growing as electronic devices become more complex and compact. {Company} is well-prepared to meet this increasing demand, leveraging its expertise and technological capabilities to deliver advanced solutions to its customers. By staying at the forefront of technological advancements and maintaining a strong commitment to quality and innovation, {Company} is poised to remain a leader in the Double-Side Rigid-Flex PCB industry.The future looks bright for {Company} as it continues to push the boundaries of what is possible in the field of Double-Side Rigid-Flex PCBs. With its unwavering dedication to excellence and customer satisfaction, the company is well-positioned to drive the advancement of electronic technology and make a lasting impact on the industry. It is clear that {Company} is a force to be reckoned with in the world of Double-Side Rigid-Flex PCB manufacturing, and its future is set to be a bright and prosperous one.

Fast Turnaround PCB Boards: Expect Quick Production and Delivery

Quick Turn PCB Boards: Revolutionizing the Electronics IndustryIn today's fast-paced world, the demand for quick and efficient manufacturing processes is higher than ever before. The electronics industry, in particular, is constantly evolving, with new technologies and products being developed at a rapid pace. This has led to a growing need for quick turn PCB boards – a demand that is being met by [Company Name].[Company Name] is a leading manufacturer of quick turn PCB boards, with a strong reputation for providing high-quality products and exceptional customer service. The company has built a solid foundation in the industry, with a team of highly skilled and experienced professionals who are dedicated to delivering cutting-edge solutions to their clients.The company's commitment to innovation and excellence has allowed them to stay ahead of the competition, and they continue to invest in state-of-the-art manufacturing equipment and technology. This has enabled them to streamline their production processes, significantly reducing lead times and delivering quick turn PCB boards to their customers in record time.One of the key factors that set [Company Name] apart from its competitors is its focus on customization. The company understands that every client has unique requirements and specifications, and they pride themselves on their ability to tailor their products to meet these individual needs. Whether it's a complex design or a tight deadline, [Company Name] has the expertise and resources to deliver a solution that exceeds expectations.Furthermore, [Company Name] places a strong emphasis on quality control. Every quick turn PCB board that leaves their facility undergoes rigorous testing and inspection to ensure that it meets the highest standards. This attention to detail has earned the company a reputation for reliability and consistency, further solidifying their position as a trusted partner in the industry.But it's not just the quality of their products that sets [Company Name] apart – it's also their unwavering commitment to customer satisfaction. The company places a strong emphasis on building lasting relationships with their clients, and they make it a priority to provide exceptional support throughout the entire manufacturing process. From initial consultation to final delivery, [Company Name] is dedicated to delivering a seamless and stress-free experience for their customers.The impact of quick turn PCB boards extends far beyond the manufacturing process. These products play a crucial role in the development of a wide range of electronic devices, from consumer electronics to medical devices and industrial equipment. By providing fast and reliable solutions, [Company Name] is helping their clients bring their innovative ideas to market in a timely manner, ultimately driving progress and growth in the electronics industry.In conclusion, quick turn PCB boards are revolutionizing the electronics industry, and [Company Name] is at the forefront of this transformation. With their dedication to innovation, excellence, and customer satisfaction, the company continues to set new standards for quick turn manufacturing, empowering their clients to stay ahead in a rapidly changing world. As the demand for quick turn PCB boards continues to grow, [Company Name] is well-positioned to lead the way, providing reliable and efficient solutions that meet the evolving needs of their customers.

The Ultimate Guide to Single Layer PCB: Everything You Need to Know

Single Layer PCB Market to Witness Significant Growth by 2028In the fast-paced world of technology, the demand for single layer PCB (Printed Circuit Board) has witnessed a significant surge over the past few years. The market for single layer PCB is projected to witness remarkable growth and is expected to reach a valuation of over $XX billion by 2028, according to a new report by [Research Firm].Single layer PCBs are widely used in various electronic devices and equipment, including mobile phones, computers, tablets, and automotive electronics, among others. The increasing adoption of single layer PCB in consumer electronics and the automotive industry is one of the key factors driving the growth of the market.[Company Name], a leading manufacturer of single layer PCB, is well-positioned to capitalize on the growing demand for single layer PCB. The company has established itself as a prominent player in the global single layer PCB market, delivering high-quality products and innovative solutions to its clients across various industries.With state-of-the-art manufacturing facilities and a team of experienced professionals, [Company Name] has been at the forefront of technological advancements in the PCB industry. The company's commitment to research and development has enabled it to offer cutting-edge single layer PCB solutions that meet the evolving needs of its customers.One of the key advantages of single layer PCB is its cost-effectiveness. As compared to multi-layer PCBs, single layer PCBs are more affordable, making them a preferred choice for manufacturers looking to minimize production costs without compromising on quality. This factor has contributed to the widespread adoption of single layer PCB in the electronics and automotive industries.Furthermore, single layer PCBs are known for their simplicity and reliability. With only one layer of substrate, single layer PCBs are easier to design, manufacture, and assemble, resulting in quicker turnaround times and reduced production lead times. This aspect is particularly important for manufacturers operating in fast-paced industries where time-to-market is a critical factor.In addition, the growing trend of miniaturization in electronic devices has created a significant demand for compact and lightweight PCBs. Single layer PCBs are well-suited for compact designs, making them an ideal choice for portable electronic devices such as smartphones, wearable devices, and IoT (Internet of Things) devices.[Company Name] is well-equipped to meet the evolving needs of the market, with a focus on delivering high-quality single layer PCBs that offer superior performance, reliability, and durability. The company's continuous investment in advanced manufacturing technologies and quality control processes has positioned it as a trusted partner for leading OEMs and electronics manufacturers worldwide.As the demand for single layer PCB continues to rise, [Company Name] is committed to expanding its production capacity and enhancing its product portfolio to cater to a diverse range of applications and industries. The company's comprehensive range of single layer PCB solutions, combined with its dedication to customer satisfaction, is expected to drive its growth and success in the global market.In conclusion, the global single layer PCB market is poised for robust growth in the coming years, fueled by the increasing demand for cost-effective, reliable, and compact PCB solutions. With [Company Name] playing a pivotal role in the market, the company is well-positioned to capitalize on the opportunities presented by the growing demand for single layer PCB, solidifying its position as a leading player in the industry.

The Importance of Electronic PCB Assembly for Your Business

In the world of cutting-edge technology and electronic advancements, Electronic PCB (Printed Circuit Board) Assembly plays a vital role in ensuring the functionality and efficiency of various electronic devices and equipment. The process of PCB assembly involves the assembly of electronic components onto a PCB, which serves as the foundation for the electrical connections that enable the device to function. With the increasing demand for complex and intricate electronic systems, the need for reliable and high-quality PCB assembly services has never been greater.One company that has been at the forefront of providing top-notch PCB assembly services is {}. With years of experience and a commitment to excellence, {} has established itself as a leading provider of electronic manufacturing services, specializing in PCB assembly, box build assembly, and electromechanical assembly. Their state-of-the-art facilities and cutting-edge technology allow them to offer a wide range of PCB assembly services to meet the needs of various industries, including aerospace, automotive, medical, telecommunications, and consumer electronics.The process of PCB assembly begins with the procurement of high-quality electronic components from trusted suppliers. Once the components are sourced, they undergo a thorough inspection and testing process to ensure their quality and integrity. The next step involves the actual assembly of the components onto the PCBs, which is carried out using advanced machinery and equipment operated by highly skilled technicians. {}'s team of experts is well-versed in the latest assembly techniques and industry best practices, ensuring that the final product meets the highest quality standards.In addition to their technical expertise, {} prides itself on its commitment to customer satisfaction. They work closely with their clients to understand their specific needs and requirements, offering customized solutions that are tailored to each project. Whether it's a small-scale prototype or a large-scale production run, {} has the capabilities to handle a wide range of PCB assembly needs, delivering high-quality, on-time, and cost-effective solutions.As a company that values innovation and continuous improvement, {} is constantly investing in new technologies and process improvements to stay ahead of the curve in the ever-evolving electronics industry. They have a dedicated research and development team that focuses on exploring new materials, techniques, and technologies to improve the efficiency and reliability of their PCB assembly services.Furthermore, {} is committed to maintaining the highest standards of quality and compliance. They are certified to ISO 9001 and ISO 13485 standards, ensuring that their processes and services adhere to the strictest quality management systems. This commitment to quality extends to their environmental responsibility, with a focus on sustainable manufacturing practices and minimizing their environmental footprint.In conclusion, the demand for high-quality PCB assembly services continues to rise as electronics become more advanced and integral to various industries. {}'s dedication to excellence and customer satisfaction has positioned them as a trusted and reliable partner for PCB assembly needs. With their advanced capabilities, commitment to quality, and continuous innovation, {} is a leader in the electronic manufacturing services industry, providing top-notch PCB assembly solutions for a wide range of applications.

Guide to Finding the Best Medical Device Printed Circuit Boards

Medical Device PCB, a cutting-edge medical technology company, is revolutionizing the healthcare industry with its innovative printed circuit boards (PCBs) designed specifically for medical devices. The company, founded in 2010, has quickly become a leader in the field of medical device PCB manufacturing, providing high-quality, reliable PCBs that are essential for the functioning of medical devices such as patient monitors, imaging equipment, surgical tools, and much more.Medical Device PCB has a state-of-the-art facility equipped with advanced technology and a team of highly skilled engineers and technicians who are dedicated to delivering the highest quality PCBs to their clients. The company prides itself on its ability to provide customized solutions to meet the unique needs of each customer, ensuring that its PCBs are not only reliable and efficient but also optimized for the specific application they will be used in.One of the key advantages of Medical Device PCB's products is their superior performance and reliability. Medical devices require PCBs that can withstand the rigors of the healthcare environment, including exposure to various chemicals, sterilization processes, and frequent use. The company's PCBs are designed and manufactured to meet these demanding requirements, providing healthcare professionals and patients with the confidence that their medical devices will operate safely and effectively.In addition to performance, Medical Device PCB places a strong emphasis on safety and regulatory compliance. The company is fully committed to ensuring that its PCBs meet the stringent quality and safety standards set forth by regulatory bodies such as the Food and Drug Administration (FDA) in the United States and similar organizations in other countries. This dedication to quality and compliance gives customers peace of mind, knowing that they are receiving PCBs that meet the highest industry standards.Medical Device PCB's products have been widely adopted by leading medical device manufacturers around the world. The company has built a strong reputation for delivering PCBs that not only meet the technical requirements of their clients but also exceed their expectations in terms of quality, reliability, and customer service. This has led to numerous long-term partnerships and repeat business, establishing Medical Device PCB as a trusted and preferred supplier in the medical device industry.In line with its commitment to innovation, Medical Device PCB is continually investing in research and development to stay at the forefront of technological advancements. The company is dedicated to staying ahead of industry trends and leveraging the latest technological breakthroughs to enhance the performance and capabilities of its PCBs. This forward-thinking approach ensures that Medical Device PCB's clients have access to the most advanced and reliable PCB solutions available.Furthermore, Medical Device PCB places a strong emphasis on sustainability and environmental responsibility. The company recognizes the importance of minimizing its environmental impact and operates in accordance with strict environmental standards. This includes responsible waste management, energy-efficient processes, and the use of eco-friendly materials whenever possible. By prioritizing sustainability, Medical Device PCB not only contributes to a healthier planet but also aligns with the values of its environmentally conscious customers.As the demand for advanced medical devices continues to grow, Medical Device PCB is well-positioned to play a significant role in shaping the future of healthcare technology. With its exceptional PCBs, unwavering commitment to quality and safety, and dedication to innovation and sustainability, the company is poised to remain a leader in the medical device industry for years to come.In conclusion, Medical Device PCB's innovative approach to PCB manufacturing, combined with its commitment to excellence and sustainability, has positioned the company as a trusted partner for medical device manufacturers worldwide. With a focus on performance, reliability, safety, and compliance, Medical Device PCB is at the forefront of delivering high-quality PCB solutions that are essential for the advancement of healthcare technology.