Top Quality PCB for Military Applications with Advanced Technology

By:Admin

With over [number] years of experience in the industry, Military PCB has established itself as a trusted partner for military and defense organizations around the world, delivering reliable and high-performance PCBs that meet the strictest military standards. The company’s dedication to excellence and innovation has made it a preferred supplier for a wide range of military applications, including aerospace, defense systems, communication systems, and more.

Military PCB’s latest technological advancement represents a significant milestone in the company’s ongoing commitment to meeting the evolving needs of the military and defense industry. This new advancement leverages state-of-the-art manufacturing processes, advanced materials, and rigorous testing to ensure that the PCBs meet the highest standards of quality and reliability. As a result, military organizations can depend on these PCBs to perform flawlessly in the most demanding and extreme operating environments.

The new technological advancement from Military PCB also includes enhancements in terms of size, weight, and power (SWaP), allowing for more compact and lightweight PCB designs without compromising performance or durability. This is particularly important for military applications, where space and weight constraints are often critical considerations. By optimizing the SWaP characteristics of its PCBs, Military PCB is enabling military organizations to achieve greater efficiency and performance in their systems and equipment.

In addition to the technological advancements, Military PCB continues to uphold its commitment to meeting the stringent quality and reliability standards required for military and defense applications. The company’s PCBs undergo rigorous testing and inspection processes to ensure that they can withstand harsh environmental conditions, extreme temperatures, vibrations, and electromagnetic interference. This level of reliability is essential for military systems that must operate flawlessly in mission-critical situations.

Furthermore, Military PCB maintains a strict adherence to industry standards and certifications, including AS9100, MIL-PRF, and IPC standards, demonstrating its unwavering dedication to delivering products that meet the highest levels of quality and performance. Military organizations can have full confidence in the reliability and durability of Military PCB’s products, knowing that they have been manufactured to the most exacting standards.

With its latest technological advancement, Military PCB is poised to further solidify its position as a premier supplier of high-quality PCBs for military and defense applications. The company’s commitment to innovation, reliability, and customer satisfaction sets it apart as a trusted partner for military organizations seeking the best-in-class PCB solutions for their critical missions.

As military and defense technologies continue to advance, the demand for high-performance and reliable PCBs will only grow. Military PCB stands ready to meet this demand with its latest technological advancement, delivering the quality, durability, and performance that military organizations rely on to ensure the success of their missions. With a proven track record of excellence and a dedication to pushing the boundaries of technological innovation, Military PCB remains at the forefront of the military-grade PCB industry, providing the solutions that power the next generation of military and defense systems.

Company News & Blog

Discover the Affordable Printed Circuit Board (PCB) Manufacturer for Your Needs

Title: Pioneering PCB Manufacturer Offers Affordable Solutions for Global Electronic IndustryIntroduction:In a rapidly evolving electronic landscape, with a growing demand for innovative and cost-effective electronic devices, the importance of Printed Circuit Boards (PCBs) cannot be overstated. PCBs serve as the backbone for electronic circuits, providing the necessary connectivity and support for components to function seamlessly. Today, we introduce an industry-leading PCB manufacturer that is revolutionizing the market with its affordable and cutting-edge solutions.Company Overview:[Company Name], an esteemed PCB manufacturer with a strong foothold in the global market, has emerged as a go-to choice for businesses seeking high-quality circuit boards at competitive prices. With a state-of-the-art manufacturing facility equipped with the latest technology, the company prioritizes customer satisfaction by offering unmatched reliability, efficient operations, and cost-effective manufacturing.Affordable and Competitive Pricing:One of the key factors that sets [Company Name] apart from its competitors is its commitment to providing cost-effective solutions. With economies of scale and streamlined operations, the company achieves competitive pricing without compromising the quality or reliability of their PCBs. By focusing on efficient production processes and leveraging global supply chains, they eliminate unnecessary overhead costs, making their products the cheapest and most affordable for the global electronic industry.Cutting-edge Technology:In order to meet the ever-increasing demands of the electronic industry, [Company Name] consistently invests in advanced technology and equipment. By continuously upgrading their manufacturing processes, they ensure that their PCBs are produced with the utmost precision and adhere to the highest industry standards. The company's cutting-edge technology allows for the fabrication of complex and intricate PCB designs, making them the ideal choice for the most innovative electronic devices.Quality Assurance:While [Company Name] offers affordable PCBs, they understand the paramount importance of ensuring quality and reliability. They have implemented a stringent quality control process at every stage of production, adhering to rigorous industry standards and regulations. The company's commitment to quality ensures that their PCBs not only meet customer specifications but also surpass their expectations, setting them apart from other manufacturers.Global Reach and Timely Delivery:With an expanding global clientele, [Company Name] has earned a reputation for its ability to meet stringent deadlines. The company prides itself on a quick turnaround time, employing efficient manufacturing processes to produce high-quality PCBs promptly. Moreover, through strategic partnerships with trusted logistics providers, they deliver products worldwide, allowing customers to access their affordable solutions regardless of their location.[Company Name] Breaks Barriers:In an industry dominated by established players, [Company Name] has successfully disrupted the market by offering PCBs at significantly lower prices, without compromising on quality. By doing so, the company aims to empower startups, small businesses, and entrepreneurs with limited budgets, allowing them to venture into the electronic industry with confidence.Future Innovations and Expansion:With its consistent growth and customer-centric approach, [Company Name] has plans for cutting-edge innovations and expansion into new markets. Their commitment to providing affordable PCB solutions aligns perfectly with the current trends in the dynamic electronic industry, ensuring that they remain at the forefront of technological advancements.Conclusion:In an era where technology is constantly evolving, the demand for reliable electronic components remains high. [Company Name], as an industry-leading PCB manufacturer, has emerged as the cheapest provider, catering to the global electronic industry's ever-growing needs. Through their commitment to affordability, cutting-edge technology, quality assurance, and timely delivery, they are revolutionizing the market and empowering businesses to thrive. As the electronic landscape continues to evolve, [Company Name] is poised to shape the industry's future by delivering cost-effective, yet exceptional, PCB solutions.

High-Quality Rapid Prototype PCB Board for Quick Turnaround

Fast Turn Prototype PCB Board (Removal of Brand Name) Company, a leading electronic manufacturing service provider, has recently announced the launch of their new fast turn prototype PCB board service. This new service is aimed at providing customers with a quick and efficient solution for producing high-quality prototype PCB boards for their electronic products.With the rapid advancement of technology, the demand for fast turn prototype PCB boards has been growing significantly. This has created a need for electronic manufacturing companies to offer efficient and timely services to their clients. Fast Turn Prototype PCB Board (Removal of Brand Name) Company has recognized this need and has responded by introducing this new service.One of the key features of the fast turn prototype PCB board service is the quick turnaround time. The company has invested in state-of-the-art manufacturing equipment and streamlined processes to ensure that they can produce prototype PCB boards in a short amount of time. This allows their clients to test and iterate on their designs more quickly, ultimately speeding up the product development cycle.In addition to the fast turnaround time, Fast Turn Prototype PCB Board (Removal of Brand Name) Company is also committed to delivering high-quality PCB boards. They have a team of experienced engineers and quality control experts who ensure that every board that leaves their facility meets the highest standards of quality and reliability. This is crucial for ensuring that the prototypes perform as expected and meet the requirements of the final product.Furthermore, the company offers a range of customization options for their fast turn prototype PCB boards. They understand that every project is unique and may have specific requirements, so they work closely with their clients to tailor the boards to their exact specifications. This level of customization sets Fast Turn Prototype PCB Board (Removal of Brand Name) Company apart from other electronic manufacturing service providers and allows them to cater to a wide range of industries and applications.Fast Turn Prototype PCB Board (Removal of Brand Name) Company has also established a strong track record of customer satisfaction. They prioritize clear communication, transparency, and collaboration with their clients throughout the entire process. This ensures that the clients are involved and informed at every stage of production, leading to a smoother and more successful project outcome.The company’s commitment to sustainability is another noteworthy aspect of their new fast turn prototype PCB board service. They have implemented eco-friendly practices in their manufacturing processes, such as using environmentally friendly materials and minimizing waste. This aligns with the growing trend of environmentally conscious manufacturing and highlights Fast Turn Prototype PCB Board (Removal of Brand Name) Company's dedication to reducing their environmental impact.Overall, the introduction of the fast turn prototype PCB board service by Fast Turn Prototype PCB Board (Removal of Brand Name) Company represents a significant step forward for the electronic manufacturing industry. With their focus on speed, quality, customization, customer satisfaction, and sustainability, they are well-positioned to meet the evolving needs of their clients and contribute to the advancement of technology and innovation.Fast Turn Prototype PCB Board (Removal of Brand Name) Company invites interested individuals and companies to learn more about their new service and explore how it can benefit their electronic product development projects. With their expertise and dedication, they are poised to make a positive impact on the industry and help their clients bring their innovative ideas to life.

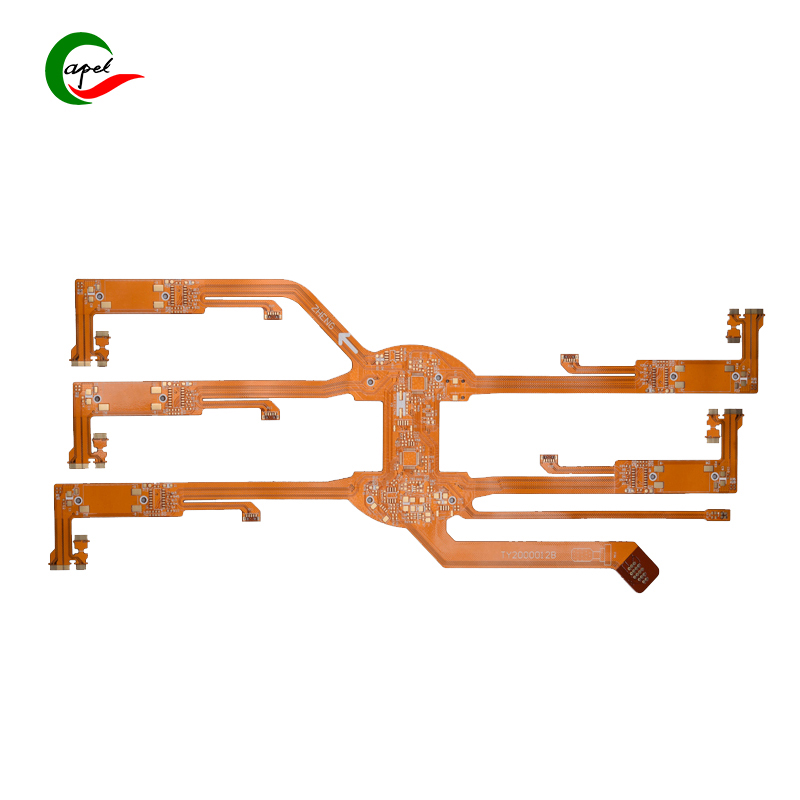

Enhance your Electronics with High-Quality FPC PCB Boards

FPC PCB Market Continues to Witness Remarkable Growth in the Electronics IndustryIn the fast-paced world of electronics, flexible printed circuitry (FPC) has emerged as a revolutionary technology. FPC printed circuit boards (PCBs) have gained significant popularity due to their flexibility, lightweight design, and superior performance. With an increasing demand for compact and flexible electronic devices, FPC PCBs have become an indispensable component in various industries. One of the prominent players in this market is a leading manufacturer specializing in FPC PCB production. FPC PCBs are groundbreaking solutions that have transformed the electronics industry. Unlike traditional rigid PCBs, FPC PCBs can be twisted, bent, or folded without compromising their functionality. These flexible boards are made using a thin layer of conductive material, typically copper, laminated onto a flexible substrate material such as polyester or polyimide. The resulting FPC PCBs offer excellent thermal stability, improved signal integrity, and enhanced overall performance. The market for FPC PCBs has witnessed remarkable growth in recent years due to technological advancements, increasing consumer demand for lightweight and portable devices, and the growing impact of the Internet of Things (IoT) on multiple industries. With its extensive expertise and state-of-the-art manufacturing facilities, the esteemed FPC PCB manufacturer has played a pivotal role in meeting this increasing demand.The company, equipped with cutting-edge technology, offers a diverse range of FPC PCBs tailored to cater to the specific needs of various industries. Their products find extensive applications in sectors such as automotive, aerospace, medical, consumer electronics, telecommunications, and industrial automation. With an unwavering commitment to quality and innovation, the company continually endeavors to provide advanced solutions for their global clientele.The automotive industry has witnessed a significant surge in the adoption of FPC PCBs due to their ability to withstand high temperatures, vibrations, and shocks. FPC PCBs are extensively used in advanced driver-assistance systems (ADAS), infotainment systems, lighting, and other critical automotive components. The company's FPC PCBs are renowned for their high reliability, superior thermal performance, and compact design, making them the preferred choice for leading automakers worldwide.Another key area where FPC PCBs have made a profound impact is the medical industry. The flexible nature and small form factor of FPC PCBs allow for the development of innovative medical devices such as wearable health monitoring systems, medical implants, and diagnostic equipment. These devices provide accurate and real-time data, enabling healthcare professionals to monitor patients remotely and improve overall patient care. The FPC PCB manufacturer's dedication to quality and conformity to stringent industry standards have earned them accolades and partnerships with top medical device manufacturers.Furthermore, the telecommunications industry heavily relies on FPC PCBs to meet the increasing demand for advanced smartphone technologies, high-speed internet connections, and wireless communication systems. FPC PCBs enable the production of compact and sleek smartphones, ensuring efficient signal transmission and minimizing signal loss. With their extensive range of FPC PCB options, the company has been a leading supplier for major telecommunications companies across the globe.As the demand for IoT devices continues to surge, FPC PCBs have become vital components in the development of smart home appliances, wearable devices, and industrial automation systems. FPC PCBs allow for seamless integration of sensors, actuators, and microcontrollers in these IoT-enabled devices, enabling efficient data exchange and automation. The FPC PCB manufacturer's commitment to innovation and continuous improvement has positioned them as a trusted partner for IoT solution providers worldwide.In conclusion, the global FPC PCB market continues to experience substantial growth, driven by the increasing demand for lightweight, compact, and flexible electronic devices. The leading FPC PCB manufacturer has played a crucial role in meeting this demand through their advanced technology, exceptional product quality, and customer-centric approach. With an unwavering focus on innovation and a commitment to providing cutting-edge solutions, they are well-positioned to lead the FPC PCB market and contribute significantly to the future of the electronics industry.

The Ultimate Guide to Flexible Printed Circuit Boards

Flex PCB Company Introduces New Innovative TechnologyFlex PCB, a leading manufacturer of flexible printed circuit boards, has recently introduced a groundbreaking new technology in the field of flexible PCBs. The company’s new technology promises to revolutionize the industry by offering unprecedented flexibility, durability, and performance for a wide range of applications.Flex PCB has been a pioneer in the development and production of flexible PCBs for over 20 years. The company has built a strong reputation for its high-quality products and innovative solutions, serving a diverse customer base in industries such as aerospace, medical devices, automotive, consumer electronics, and more. With its team of experienced engineers and state-of-the-art manufacturing facilities, Flex PCB has consistently pushed the boundaries of what is possible with flexible PCB technology.The company’s latest innovation in flexible PCB technology is set to further solidify its position as an industry leader. The new technology offers improved flexibility and bendability, allowing for easier integration into compact and unconventional designs. This makes it ideal for applications where traditional rigid PCBs would be unsuitable, such as wearable devices, automotive interiors, and medical implants.Another key feature of the new technology is its enhanced durability. Flex PCB’s new flexible PCBs are designed to withstand harsh environments, including high temperatures, moisture, and mechanical stress. This makes them suitable for use in applications that require high reliability and long-term performance, such as aerospace and automotive electronics.In addition to flexibility and durability, the new technology also offers superior electrical performance. The new flexible PCBs boast low impedance, high signal integrity, and excellent thermal management, making them suitable for high-speed and high-frequency applications. This opens up new possibilities for designers and engineers in industries such as telecommunications, data centers, and IoT devices."We are thrilled to introduce our latest innovation in flexible PCB technology," said the CEO of Flex PCB. "Our new flexible PCBs offer unmatched flexibility, durability, and performance, opening up new possibilities for our customers to create groundbreaking products. We believe that this technology will have a significant impact on the industry and we are excited to see the innovative applications that will emerge as a result."The company’s new technology has already garnered significant interest from customers and partners in a wide range of industries. Flex PCB is currently working closely with leading companies to integrate its new flexible PCBs into their next-generation products, paving the way for new advancements in areas such as wearable technology, automotive electronics, and medical devices.Flex PCB’s new flexible PCB technology is now available for sampling, with mass production set to begin in the coming months. With its unmatched combination of flexibility, durability, and performance, the company’s new technology is poised to reshape the future of flexible PCBs and enable new possibilities for innovative product design.As Flex PCB continues to push the boundaries of flexible PCB technology, the industry can expect even more groundbreaking innovations from the company in the years to come. With its relentless focus on quality, innovation, and customer satisfaction, Flex PCB is set to maintain its position as a leader in the field of flexible PCB manufacturing, driving the industry forward with its cutting-edge solutions.

Innovations in Double-Side Rigid-Flex PCB Technology

The demand for Double-Side Rigid-Flex PCBs is on the rise due to their numerous advantages in electronic applications. These innovative circuit boards are becoming increasingly popular in industries such as aerospace, medical devices, automotive, and consumer electronics. One company that has been at the forefront of producing high-quality Double-Side Rigid-Flex PCBs is {Company}.{Company} is a leading manufacturer of advanced electronic components, specializing in the development and production of Double-Side Rigid-Flex PCBs. The company has earned a reputation for delivering reliable and cutting-edge solutions to meet the evolving needs of the electronics industry. With a strong focus on research and development, {Company} has been able to stay ahead of the curve and provide its customers with state-of-the-art products that exceed industry standards.Double-Side Rigid-Flex PCBs offer a unique combination of flexibility and rigidity, making them suitable for a wide range of applications. These circuit boards are designed to withstand demanding environmental conditions, making them perfect for use in harsh operating environments. The flexibility of Rigid-Flex PCBs allows for greater design freedom, enabling engineers to create smaller, lighter, and more compact electronic devices. By eliminating the need for multiple interconnects, Double-Side Rigid-Flex PCBs also reduce overall system complexity and improve reliability.{Company} prides itself on its commitment to quality and innovation. The company's state-of-the-art manufacturing facilities and rigorous quality control processes ensure that every Double-Side Rigid-Flex PCB that leaves its factory meets the highest standards of performance and reliability. {Company} also offers customized solutions to meet the specific needs of its customers, working closely with them to develop tailored Double-Side Rigid-Flex PCBs for their unique applications.In addition to its focus on product quality, {Company} is also dedicated to sustainability and environmental responsibility. The company employs eco-friendly manufacturing practices and utilizes materials that are compliant with industry regulations. By prioritizing sustainability, {Company} aims to minimize its environmental impact and contribute to a cleaner, greener future.With a team of experienced and skilled professionals, {Company} is uniquely positioned to provide comprehensive support to its customers, from initial design concept to full-scale production. The company's engineers work closely with customers to understand their specific requirements, providing expert guidance and technical expertise to ensure the successful implementation of Double-Side Rigid-Flex PCBs in their electronic applications.The demand for Double-Side Rigid-Flex PCBs is expected to continue growing as electronic devices become more complex and compact. {Company} is well-prepared to meet this increasing demand, leveraging its expertise and technological capabilities to deliver advanced solutions to its customers. By staying at the forefront of technological advancements and maintaining a strong commitment to quality and innovation, {Company} is poised to remain a leader in the Double-Side Rigid-Flex PCB industry.The future looks bright for {Company} as it continues to push the boundaries of what is possible in the field of Double-Side Rigid-Flex PCBs. With its unwavering dedication to excellence and customer satisfaction, the company is well-positioned to drive the advancement of electronic technology and make a lasting impact on the industry. It is clear that {Company} is a force to be reckoned with in the world of Double-Side Rigid-Flex PCB manufacturing, and its future is set to be a bright and prosperous one.

Smart Glasses PCB: The Future of VR Technology

Virtual reality (VR) technology has been making waves in the tech industry for several years now, and the latest development in this field comes in the form of VR smart glasses PCB. These innovative PCBs are set to revolutionize the way we experience VR, offering a new level of immersion and interactivity.The VR smart glasses PCB is a crucial component in the development of VR smart glasses, which are rapidly gaining popularity in the consumer market. These glasses offer users a way to experience virtual reality without being tethered to a computer or gaming console. Instead, they can simply put on a pair of glasses and be transported to a virtual world.One of the key players in the development of VR smart glasses PCB is {Company Name}, a leading provider of advanced PCB solutions. With a team of experts in the field of VR technology, {Company Name} is at the forefront of developing PCBs that can handle the complex demands of VR smart glasses.{Company Name} has been in the PCB industry for over a decade, with a strong track record of delivering high-quality, reliable PCB solutions to a wide range of industries. Their expertise in engineering and manufacturing PCBs has positioned them as a trusted partner for companies looking to push the boundaries of technology.The VR smart glasses PCB developed by {Company Name} is designed to meet the demanding requirements of VR technology. These PCBs are equipped with the latest advancements in circuitry design and manufacturing techniques, ensuring that they can handle the high-speed data processing and low-latency communication that VR smart glasses require.In addition to their technical capabilities, {Company Name} also places a strong emphasis on quality and reliability. Each VR smart glasses PCB undergoes rigorous testing and inspection to ensure that it meets the highest standards of performance and durability. This commitment to quality has earned {Company Name} a reputation as a leader in the PCB industry.With the launch of the VR smart glasses PCB, {Company Name} is poised to make a significant impact on the VR market. These PCBs will enable manufacturers of VR smart glasses to create products that offer an unparalleled level of immersion and realism, opening up new possibilities for entertainment, gaming, and other applications.The potential applications of VR smart glasses are vast, and {Company Name} is ready to support the development of these innovative products. With their extensive knowledge of PCB design and manufacturing, as well as their commitment to quality, {Company Name} is well-positioned to help companies bring their VR smart glasses to market.In conclusion, the development of VR smart glasses PCB by {Company Name} represents a significant step forward for the VR industry. These PCBs will enable the creation of VR smart glasses that offer a new level of immersion and interactivity, opening up exciting possibilities for entertainment, gaming, and more. With their expertise and commitment to quality, {Company Name} is set to play a key role in shaping the future of VR technology.

Revolutionary Advancements in Flexible Printed Circuit Boards Unveiled

Advanced FPC, a leading manufacturer of flexible printed circuits, recently announced its expansion plans and commitment to innovation in the electronics industry. With a keen focus on providing advanced solutions to its clients, the company aims to revolutionize the way electronic devices are designed and manufactured.Established in [year], Advanced FPC has rapidly grown into a trusted partner for numerous well-known consumer electronics brands. Its expertise lies in the production of high-quality and reliable flexible printed circuit boards (FPCs) that are critical components in the creation of various electronic devices. The company's success can be attributed to its dedication to research and development, maintaining strong relationships with clients, and constantly adapting to the dynamic market trends.Advanced FPC is known for its state-of-the-art manufacturing facilities equipped with cutting-edge technology. These facilities allow the company to produce FPCs with high precision, ensuring an excellent performance and durability of the final products. With an emphasis on quality control and rigorous testing procedures, Advanced FPC guarantees that its circuits meet strict industry standards, surpassing customer expectations.To facilitate its expansion plans, Advanced FPC recently invested heavily in research and development. The company established a dedicated team of engineers and researchers to focus on the advancement of flexible printed circuit technology. Their goal is to develop groundbreaking solutions that address the current limitations in electronic device design and functionality.One of the key areas of focus for Advanced FPC is enhancing the flexibility and durability of its circuits. By leveraging their expertise in materials science and conducting extensive research, the company aims to create FPCs that can withstand more bending and twisting without compromising their performance. This breakthrough technology will enable the production of foldable or wearable electronic devices, opening up new possibilities for manufacturers and consumers alike.Additionally, Advanced FPC aims to improve the thermal management capabilities of its circuits. As electronic devices become smaller and more powerful, efficient heat dissipation is crucial to prevent overheating and potential damage. The company is investing in new materials and thermal management techniques to ensure that its FPCs can efficiently dissipate heat in demanding applications. This development will be especially valuable in industries such as aerospace, automotive, and medical devices.Recognizing the emerging trend of Internet of Things (IoT), Advanced FPC is also focusing on integrating smart features into its circuits. By incorporating sensors, antennas, and communication modules directly onto the FPCs, the company aims to facilitate seamless connectivity and enhance the functionality of IoT devices. This innovation will enable manufacturers to create smaller, smarter, and more efficient IoT products for various applications.In addition to these technological advancements, Advanced FPC is committed to sustainability and environmental responsibility. The company actively incorporates green practices into its manufacturing processes, reducing waste, and minimizing its carbon footprint. By adhering to strict environmental regulations and promoting the use of eco-friendly materials, Advanced FPC aims to contribute to a sustainable future.With its ambitious expansion plans and dedication to innovation, Advanced FPC is well-positioned to remain a leader in the flexible printed circuit industry. By consistently pushing the boundaries of technology, the company aims to provide its clients with cutting-edge solutions that meet the evolving demands of the electronics market. Advanced FPC's commitment to quality, advanced manufacturing techniques, and sustainability further establish it as a trusted partner for companies seeking reliable flexible printed circuit solutions.

Affordable PCB Prices: Get the Best Deals on Circuit Boards

The price of PCBs has been a hot topic in the electronics industry recently. With the growing demand for electronic products, the price of PCBs has been fluctuating, affecting the cost of manufacturing for many companies. The price of PCBs has a significant impact on the final cost of electronic products, and therefore, it is closely monitored by manufacturers and suppliers alike.In recent news, the price of PCBs has experienced a slight increase due to various factors such as the increase in raw material costs, supply chain disruptions, and growing demand. This price increase has put pressure on many manufacturers who rely on PCBs for their products. As a result, companies are looking for ways to mitigate the impact of the price increase on their production costs.One company that has been affected by the recent increase in PCB prices is {}. This company is a leading manufacturer of electronic devices, and PCBs are a crucial component of their products. The increase in PCB prices has directly impacted their manufacturing costs, and as a result, they are exploring various strategies to manage this challenge.{} has been working closely with their PCB suppliers to negotiate better prices and secure long-term contracts. They are also exploring the possibility of redesigning their products to reduce PCB usage and minimize the impact of the price increase. Additionally, the company is considering diversifying their PCB suppliers to ensure a stable supply chain and reduce dependency on a single supplier.Furthermore, the company is investing in research and development to explore alternative materials and manufacturing processes that could potentially lower the cost of PCBs. By investing in innovation, they aim to reduce their reliance on traditional PCB materials and find more cost-effective solutions.In addition to these efforts, {} has been working closely with their customers to communicate the challenges they are facing due to the increase in PCB prices. By being transparent about the situation, the company is building trust with their customers and finding ways to work together to manage the impact of the price increase. This open communication has allowed the company to maintain strong relationships with their customers and find mutually beneficial solutions.Despite the challenges posed by the increase in PCB prices, {} remains optimistic about the future. They are confident that their proactive approach to managing this challenge will help them mitigate the impact on their manufacturing costs and maintain their competitive position in the market. By collaborating with their suppliers, investing in innovation, and working closely with their customers, they are confident that they can overcome this challenge and continue to deliver high-quality products to their customers.In conclusion, the increase in PCB prices has posed significant challenges for companies in the electronics industry. However, proactive measures such as negotiating with suppliers, investing in innovation, and maintaining open communication with customers can help companies manage the impact of the price increase and ensure continued success in the market. As companies like {} continue to navigate these challenges, the industry as a whole will continue to evolve and adapt to the changing market dynamics.

High-Quality Semi-Rigid Flex PCB for Your Electronic Needs

Semi Rigid Flex PCB is a type of flexible printed circuit board (PCB) that offers a unique combination of flexibility and rigidity, making it suitable for a wide range of applications. This innovative technology is now being offered by {Company Name}, a leading provider of high-quality PCB solutions.{Company Name} has been at the forefront of PCB manufacturing and assembly for over a decade. With a strong focus on innovation and quality, the company has built a reputation for delivering cutting-edge PCB products to a diverse range of industries. With the introduction of Semi Rigid Flex PCB, {Company Name} is poised to further strengthen its position in the market as a trusted PCB supplier.Semi Rigid Flex PCB is designed to provide a flexible solution for applications that require a combination of flexibility and rigidity. This makes it ideal for use in products where space is limited, and where traditional rigid PCBs may not be suitable. The semi-rigid nature of these PCBs allows for bending and folding, while still maintaining the necessary rigidity for component mounting and assembly.{Company Name} understands the unique demands of modern technology, and the need for advanced PCB solutions to meet these demands. With the introduction of Semi Rigid Flex PCB, the company aims to address the evolving needs of its customers and provide them with a versatile and reliable PCB solution that can be tailored to their specific requirements.The use of Semi Rigid Flex PCB offers numerous benefits for product designers and manufacturers. The flexibility of these PCBs allows for greater freedom in designing complex and compact electronic products, while their rigidity ensures the reliability and durability of the final product. These PCBs can also be used to minimize the need for connectors and wires, thereby reducing the overall size and weight of the final product.{Company Name} has invested heavily in research and development to offer a range of custom semi-rigid flex PCB solutions that meet the unique requirements of its clients. Whether it is a complex aerospace application or a high-density consumer electronics product, {Company Name} has the expertise and capabilities to deliver custom semi-rigid flex PCBs that meet the highest quality standards.In addition to offering high-quality products, {Company Name} also prides itself on providing exceptional customer service and support. The company's team of experienced engineers and technical experts work closely with customers to understand their specific needs and develop customized solutions that meet their requirements. This level of commitment and dedication has helped {Company Name} build long-lasting relationships with its clients and establish itself as a trusted partner in the PCB industry.{Company Name}'s investment in Semi Rigid Flex PCB technology reflects its ongoing commitment to innovation and excellence. By offering this advanced PCB solution, the company aims to continue providing its customers with cutting-edge products that help them stay ahead in a competitive market. With the flexibility and rigidity offered by Semi Rigid Flex PCB, {Company Name} is well-positioned to meet the evolving needs of its clients and provide them with the high-quality PCB solutions they need to succeed.In conclusion, the introduction of Semi Rigid Flex PCB by {Company Name} represents a significant step forward in the PCB industry. This innovative technology offers a unique combination of flexibility and rigidity, making it suitable for a wide range of applications. With its commitment to quality, innovation, and customer satisfaction, {Company Name} is well-equipped to lead the way in delivering advanced PCB solutions to its clients.

Ultimate Guide to Flex Circuit PCBs: Everything You Need to Know

Flex Circuit PCB Company Unveils Cutting-Edge Technology to Enhance Electronics ManufacturingFlex Circuit PCB Company, a leading provider of flexible printed circuit boards, has recently introduced an innovative technology that is set to revolutionize the electronics manufacturing industry. The company, known for its commitment to delivering high-quality and reliable PCB solutions, is poised to make a significant impact with its latest development.With a strong focus on providing state-of-the-art solutions to meet the evolving needs of the electronics industry, Flex Circuit PCB Company has established itself as a trusted partner for a wide range of applications. The company’s dedication to innovation and customer satisfaction has been a driving force behind its success, and the unveiling of its latest technology is a testament to this commitment.The newly introduced technology by Flex Circuit PCB Company promises to deliver numerous benefits to electronics manufacturers. By leveraging advanced materials and manufacturing processes, the technology enables the production of flexible printed circuit boards with enhanced performance and reliability. This is particularly significant for industries such as consumer electronics, automotive, medical devices, and aerospace, where the demand for high-quality PCB solutions continues to grow.One of the key highlights of the technology is its ability to provide exceptional flexibility and durability, making it well-suited for applications that require bending and flexing of the PCB. This capability opens up a wide range of possibilities for product design and innovation, allowing manufacturers to explore new concepts and solutions that were previously not feasible with traditional rigid PCBs.In addition to flexibility and durability, the technology also offers superior electrical performance, with excellent signal integrity and thermal management. This is essential for applications that require high-speed data transmission, precision sensing, and efficient heat dissipation. By incorporating these advanced capabilities into their products, electronics manufacturers can achieve higher levels of performance and reliability, ultimately leading to improved end-user experiences.Furthermore, the technology is designed to streamline the manufacturing process, resulting in increased efficiency and cost savings for electronics manufacturers. With optimized material utilization and simplified assembly processes, the technology enables faster production cycles and reduced production costs, without compromising on quality or performance.“We are incredibly excited to introduce this cutting-edge technology to the market,” said [Spokesperson], [Title] at Flex Circuit PCB Company. “We believe that this technology will redefine the possibilities for electronics manufacturers, empowering them to create innovative products that meet the demands of today’s dynamic market. At Flex Circuit PCB Company, we remain committed to pushing the boundaries of what is possible with flexible printed circuit boards, and we are confident that this technology will deliver exceptional value to our customers.”The launch of this groundbreaking technology underscores Flex Circuit PCB Company’s ongoing commitment to innovation and excellence. With a track record of delivering reliable and high-performance PCB solutions, the company continues to set new standards in the industry, and its latest development is poised to further solidify its position as a leading provider of flexible printed circuit boards.As the demand for flexible and high-performance PCB solutions continues to grow, Flex Circuit PCB Company’s new technology is expected to gain significant traction among electronics manufacturers looking to gain a competitive edge. With its unparalleled capabilities and potential to drive innovation, the technology is set to play a pivotal role in shaping the future of electronics manufacturing.In conclusion, Flex Circuit PCB Company’s latest technology represents a significant milestone in the electronics industry, offering a compelling solution for manufacturers seeking to enhance their products with flexible and high-performance PCBs. With its advanced capabilities and potential for driving innovation, the technology is poised to make a lasting impact on the industry, further cementing Flex Circuit PCB Company’s position as a pioneer in the field of flexible printed circuit boards.