What You Need to Know About Flexible PCB Boards

By:Admin

In the rapidly evolving world of electronic design and manufacturing, companies are constantly seeking innovative solutions to improve the performance and efficiency of their products. One such company that has successfully achieved this is {Company X}, a leading provider of advanced electronic components and solutions. Through the integration of flexible PCB board technology, {Company X} has been able to significantly enhance the reliability and flexibility of their products, setting new standards in the industry.

Flexible PCB boards, also known as flex circuits, are a type of electronic circuitry that is manufactured using flexible plastic substrates. Unlike traditional rigid PCB boards, flex circuits offer a high degree of flexibility and can be bent, folded, or twisted to fit into tight spaces or conform to irregular shapes. This unique characteristic makes them ideal for applications where space is limited or where mechanical flexibility is required, such as in wearable devices, medical implants, automotive interiors, and aerospace systems.

{Company X} has been at the forefront of integrating flexible PCB board technology into their product development process, recognizing the numerous advantages that it offers. By leveraging the expertise of their advanced R&D team and investing in state-of-the-art manufacturing capabilities, {Company X} has successfully developed a wide range of products that incorporate flexible PCB boards, ranging from consumer electronics to industrial control systems.

One of the key benefits of using flexible PCB boards is the increased reliability they provide. Traditional rigid PCB boards are susceptible to mechanical stress and thermal expansion, leading to potential failure over time. In contrast, flex circuits are designed to withstand bending and flexing without compromising their electrical performance, making them highly durable and reliable. This improved resilience is particularly valuable in applications that are subject to constant movement or vibration, as it ensures consistent performance and longevity.

Furthermore, the integration of flexible PCB board technology has enabled {Company X} to achieve new levels of miniaturization and space efficiency in their products. With the ability to bend and conform to non-linear shapes, flex circuits allow for the compact and efficient design of electronic systems, reducing overall size and weight while maintaining functionality. This has opened up new possibilities for {Company X} to develop cutting-edge products that are smaller, lighter, and more versatile, meeting the evolving needs of their customers across various industries.

In addition to these technical advantages, {Company X} has also positioned itself as a leader in environmental sustainability through the use of flexible PCB boards. With their reduced material consumption and lighter weight, flex circuits contribute to a lower environmental impact compared to traditional rigid PCB boards, aligning with {Company X}'s commitment to sustainable practices and responsible manufacturing.

Looking ahead, {Company X} is dedicated to further advancing the integration of flexible PCB board technology into their future product offerings. With ongoing research and development efforts focused on pushing the boundaries of design and innovation, {Company X} aims to continue setting new benchmarks for efficiency, reliability, and functionality in the electronic components industry. By staying at the forefront of technological advancements and embracing the potential of flexible PCB boards, {Company X} is poised to empower their customers with next-generation solutions that drive progress and success in the digital age.

Company News & Blog

Where to Find Local PCB Assembly Services

article on PCB assembly services and capabilities. ---In today's technologically advanced world, the demand for high-quality printed circuit board (PCB) assembly services has been on the rise. As businesses and industries continue to develop and innovate, the need for reliable and efficient PCB assembly has become increasingly important. This is why seeking out a reputable and experienced PCB assembly service provider is essential for ensuring the success and durability of electronic products.One such company that has been making waves in the PCB assembly industry is {}. With a strong commitment to quality, precision, and customer satisfaction, {} has established itself as a leading provider of PCB assembly services.{} has a state-of-the-art facility that is equipped with advanced machinery and technology to handle the most complex PCB assembly requirements. The company offers a comprehensive range of PCB assembly services, including surface mount technology (SMT) assembly, through-hole assembly, mixed technology assembly, and electronic testing.The SMT assembly process involves mounting components directly onto the surface of a PCB, which allows for a higher component density and greater precision. With their expertise in SMT assembly, {} is capable of handling intricate and miniaturized PCB designs, ensuring that each component is placed with utmost accuracy.In addition to SMT assembly, {} also specializes in through-hole assembly, which involves the insertion of component leads through holes on the PCB and soldering them onto the opposite side. This traditional assembly method is still widely used for components that require strong mechanical bonds and high power handling capability.For projects that require a combination of SMT and through-hole components, {} offers mixed technology assembly services. Their skilled technicians are well-versed in handling complex PCB layouts that incorporate both SMT and through-hole components, ensuring a seamless interface between the two assembly processes.Furthermore, {} is dedicated to maintaining the highest quality standards in PCB assembly. The company employs stringent quality control measures at every stage of the assembly process, from component procurement to final inspection. By adhering to industry best practices and rigorous quality checks, {} ensures that their assembled PCBs meet or exceed the performance and reliability expectations of their clients.Electronic testing is another crucial aspect of PCB assembly, and {} is well-equipped to perform a variety of testing procedures to verify the functionality and integrity of assembled PCBs. With in-circuit testing, flying probe testing, and functional testing capabilities, {} is able to identify and rectify any potential defects or malfunctions before the final product is delivered to the customer.In addition to their comprehensive PCB assembly services, {} takes pride in offering personalized customer support and collaboration throughout the entire assembly process. From initial design consultations to post-assembly support, their team of experienced engineers and technicians work closely with clients to ensure that their specific requirements and expectations are met.With a strong emphasis on continuous improvement and innovation, {} is constantly investing in research and development to stay ahead of the curve in PCB assembly technology. By staying abreast of the latest industry trends and advancements, {} is able to offer cutting-edge solutions that cater to the evolving needs of their clients across various sectors, including aerospace, automotive, telecommunications, and consumer electronics.In conclusion, the demand for high-quality PCB assembly services continues to grow, and {} is at the forefront of delivering exemplary solutions to meet this demand. With their extensive capabilities, commitment to quality, and customer-centric approach, {} has solidified its position as a trusted partner for businesses seeking reliable and efficient PCB assembly services. As technology continues to advance, the importance of partnering with a reputable and experienced PCB assembly service provider like {} cannot be overstated.

Top Reasons to Choose Local PCB Assembly Services

In today's rapidly evolving technology landscape, the demand for high-quality PCB assembly services is higher than ever before. As businesses and individuals alike strive to bring innovative electronic products to the market, the need for reliable, efficient, and cost-effective PCB assembly has become paramount. For those seeking top-notch PCB assembly services, the search for "PCB assembly near me" often yields numerous results. However, one company that consistently stands out from the rest is {Company Name}.{Company Name} is a leading provider of PCB assembly services, offering a comprehensive range of solutions to meet the diverse needs of its clients. With state-of-the-art facilities, cutting-edge technology, and a team of highly skilled professionals, {Company Name} has earned a reputation for delivering exceptional results and exceeding customer expectations.One of the key factors that sets {Company Name} apart from other PCB assembly providers is its commitment to quality. The company adheres to strict quality control measures at every stage of the assembly process, ensuring that each PCB meets the highest standards for performance, reliability, and durability. Additionally, {Company Name} is equipped with advanced testing and inspection equipment to detect and rectify any potential issues before the final product is delivered to the client.In addition to its unwavering dedication to quality, {Company Name} also prides itself on its ability to offer flexible and customizable solutions. Whether clients require low-volume prototype assembly or high-volume production runs, {Company Name} has the capabilities and expertise to accommodate their specific needs. The company's team of engineering and manufacturing experts works closely with clients to understand their unique requirements and develop tailored solutions that align with their goals and budget.Furthermore, {Company Name} places a strong emphasis on efficiency and cost-effectiveness. By leveraging advanced manufacturing techniques, streamlined processes, and a focus on continuous improvement, the company is able to optimize production timelines and minimize costs without compromising on quality. This enables clients to bring their products to market faster and more affordably, giving them a competitive edge in their respective industries.As part of its commitment to delivering exceptional customer service, {Company Name} also offers comprehensive support and guidance throughout the entire PCB assembly process. From initial design and prototyping to final production and delivery, the company's team remains dedicated to ensuring that clients are fully satisfied with the results. This level of hands-on, personalized attention sets {Company Name} apart as a trusted partner for PCB assembly needs.When it comes to selecting a PCB assembly provider, it's crucial to choose a company that not only has the technical capabilities and expertise but also a proven track record of delivering top-notch results. For those in search of "PCB assembly near me," {Company Name} has consistently proven itself as a reliable and highly capable partner. Whether clients are in the aerospace, automotive, medical, telecommunications, or any other industry, {Company Name} is equipped to meet their PCB assembly needs with precision, efficiency, and excellence.With its steadfast commitment to quality, flexibility, efficiency, and customer satisfaction, {Company Name} sets the standard for PCB assembly services. Whether clients are in search of a partner for prototyping, small-scale production, or large-scale manufacturing, {Company Name} is poised to deliver unparalleled results. As the demand for high-quality PCB assembly services continues to grow, {Company Name} remains at the forefront, ready to meet the evolving needs of its clients and elevate the standards of electronic product manufacturing.

Top Tips for Creating a High-Quality PCB Board Prototype

In the fast-paced world of technology, the demand for cutting-edge electronic components is at an all-time high. As companies strive to stay ahead of the curve, the need for reliable and efficient PCB board prototypes has become increasingly crucial. In response to this growing demand, {Company Name} is proud to announce the launch of their latest PCB board prototype, which promises to revolutionize the industry.With over 20 years of experience in the electronic manufacturing industry, {Company Name} has established itself as a leading provider of high-quality PCB solutions. Their commitment to excellence and innovation has earned them a stellar reputation among their clients, who rely on their expertise to bring their electronic designs to life.The new PCB board prototype from {Company Name} is designed to meet the evolving needs of the industry, offering advanced features and capabilities that set it apart from the competition. With a focus on precision and reliability, this prototype is poised to redefine the standard for electronic components, providing clients with a dependable and efficient solution for their projects.One of the key features of the new PCB board prototype is its advanced design and construction, which allows for seamless integration into a wide range of electronic applications. Whether it's a complex circuit board for a cutting-edge technology product or a simple prototype for a new invention, this PCB board is equipped to handle the demands of the most ambitious projects.In addition to its technical capabilities, the new PCB board prototype from {Company Name} also offers unparalleled flexibility and customization options. Clients have the freedom to tailor the prototype to their exact specifications, ensuring that it meets their unique requirements and performance standards. This level of customization is a game-changer for companies looking to differentiate themselves in the market and stay ahead of the competition.Furthermore, the PCB board prototype is backed by {Company Name}'s unwavering commitment to quality and customer satisfaction. Each prototype undergoes rigorous testing and inspection to ensure that it meets the highest standards of performance and reliability. This dedication to excellence is a testament to {Company Name}'s ongoing mission to deliver superior electronic solutions to their clients.In the ever-evolving landscape of electronic manufacturing, having access to a reliable and efficient PCB board prototype is essential for companies looking to stay competitive. With the launch of their latest prototype, {Company Name} has once again demonstrated their leadership in the industry, providing clients with a solution that exceeds their expectations and sets new standards for electronic components.As the demand for advanced electronic solutions continues to grow, {Company Name} remains at the forefront of innovation, driving the industry forward with their cutting-edge PCB board prototypes. With a steadfast commitment to quality, reliability, and customer satisfaction, they are poised to shape the future of electronic manufacturing and set new benchmarks for excellence in the field.In conclusion, the new PCB board prototype from {Company Name} is a testament to their unwavering dedication to innovation and excellence. With its advanced features, customization options, and commitment to quality, this prototype is set to redefine the industry and empower companies to bring their most ambitious electronic projects to life. As the demand for reliable and efficient electronic components continues to grow, {Company Name} is proud to lead the charge, providing clients with a solution that exceeds their expectations and sets new standards for the industry.

Revolutionize Your Virtual Reality Experience with Cutting-edge Circuit Boards

Virtual reality (VR) has taken the tech industry by storm, revolutionizing the way people experience entertainment and interact with digital content. One crucial component that makes VR technology possible is the VR circuit board, which acts as the backbone of immersive experiences. In recent news, a leading manufacturer of VR circuit boards has emerged, offering state-of-the-art solutions that promise to enhance the VR experience like never before.{Company Name}, a pioneer in the field of VR circuit boards, prides itself on producing cutting-edge technology that pushes the boundaries of virtual reality. With a team of skilled engineers and designers, the company aims to deliver immersive and high-performance solutions that cater to the growing demands of the VR industry.One of the key aspects of {Company Name}'s VR circuit boards is their commitment to scalability. Understanding that VR technology is a rapidly evolving field, the company ensures that its circuit boards are designed to accommodate future advancements. This flexibility enables consumers to upgrade their VR systems without the need for significant hardware changes, making them cost-effective and future-proof.{Company Name}'s VR circuit boards also boast a high level of integration, ensuring seamless communication between the various components of a VR system. By minimizing latency and optimizing data transfer, users can enjoy a smooth and responsive virtual reality experience. This integration is particularly crucial for applications that require real-time tracking and gesture recognition, enhancing the overall immersion and realism.Another standout feature of {Company Name}'s VR circuit boards is their robustness and reliability. Recognizing the intensive nature of VR applications, the company designs its circuit boards to handle the demanding workloads with ease. This durability not only ensures a longer lifespan for the VR systems but also reduces the chances of technical disruptions during usage, providing a worry-free experience for users.Furthermore, {Company Name} prioritizes user comfort and ergonomics in its VR circuit board designs. By minimizing power consumption and heat generation, as well as incorporating advanced cooling mechanisms, the company aims to create VR systems that are comfortable to wear for extended periods. This focus on user-centric design allows for more enjoyable and immersive experiences without the discomfort associated with heat accumulation.The commitment to innovation and quality is evident in the range of VR circuit boards offered by {Company Name}. From entry-level options suitable for casual users to high-performance boards catering to the needs of professionals and enthusiasts, the company ensures that there is a VR circuit board for every individual's requirements. This versatility allows for wider accessibility to the mind-boggling world of virtual reality.In addition to its product excellence, {Company Name} also focuses on providing exceptional customer support. The company understands that the VR industry can be intimidating for some users, and therefore, offers comprehensive after-sales assistance to guide users through setup and troubleshooting processes. This commitment to customer satisfaction has earned {Company Name} a loyal and satisfied user base.As virtual reality continues to transcend boundaries and become an integral part of various industries, {Company Name} remains at the forefront of delivering groundbreaking VR circuit boards. With its dedication to innovation, quality, and user experience, the company is set to shape the future of virtual reality technology.In conclusion, {Company Name}'s VR circuit boards have emerged as game-changers in the virtual reality industry. Their commitment to scalability, integration, reliability, and user comfort sets them apart from the competition. By offering a range of circuit boards for different user needs and providing exceptional customer support, {Company Name} is well-positioned to leave a lasting impact on the world of virtual reality.

Explore the Growing Importance of Flex Printed Circuit Boards in Today's Technological Landscape

[News Title][Date][City, State] - [Company Name], a leading manufacturer in the electronics industry, has announced the launch of their revolutionary Flex Printed Circuit Board (FPCB). With its cutting-edge technology and innovative design, this Flex PCB is set to revolutionize the electronics market and drive new possibilities in various industries.The Flex PCB is a flexible type of printed circuit board that offers a wide range of benefits over traditional rigid boards. This flexible circuit board allows for easier and more efficient design and assembly of electronic devices, encouraging manufacturers to explore new possibilities in product development. With its ability to bend and flex, the FPCB can be integrated into various applications, including wearable devices, medical devices, automotive electronics, aerospace components, and more.In today's fast-paced and ever-evolving technological landscape, the demand for flexible circuit boards has been steadily increasing. The Flex PCB market is expected to reach a value of $27.2 billion by 2025, according to a recent report by MarketsandMarkets. This growth is primarily driven by the increasing adoption of wearable devices, the rise in demand for consumer electronics, and the expansion of the automotive and aerospace industries.[Company Name], with their extensive experience and expertise in the electronics manufacturing sector, is well-positioned to capitalize on this market opportunity. The company specializes in delivering high-quality, innovative solutions to its customers, and the launch of the Flex PCB further solidifies their commitment to staying at the forefront of technological advancements.Designed with efficiency and reliability in mind, the Flex PCB manufactured by [Company Name] offers numerous advantages. Its flexibility allows for the creation of compact and lightweight electronic devices, enabling manufacturers to improve the portability and overall functionality of their products. Moreover, the Flex PCB reduces the overall cost of production by eliminating the need for additional connectors and cables, making it an economical choice for manufacturers.The Flex PCB also ensures enhanced durability and reliability. It can withstand high levels of stress, making it suitable for applications in harsh environments or products subjected to repetitive bending or flexing. This robustness improves the overall lifespan of electronic devices and reduces the need for frequent repairs or replacements, saving both time and money for end-users.Furthermore, [Company Name]'s Flex PCB incorporates advanced materials and manufacturing processes, ensuring exceptional signal integrity and precise circuit routing. This results in improved performance and faster transmission speeds, meeting the demands of modern technologies such as 5G, Internet of Things (IoT), and artificial intelligence (AI).With their state-of-the-art manufacturing facilities and a team of highly skilled engineers and technicians, [Company Name] guarantees the production of reliable and high-quality Flex PCBs that meet the specific requirements of their customers. They are committed to providing customized solutions and excellent customer service, ensuring a seamless integration of the Flex PCB into their clients' electronic devices.As the electronics industry continues to evolve, [Company Name] is dedicated to remaining at the forefront of innovation. With the launch of their Flex PCB, they are set to disrupt the market and pave the way for new possibilities in electronics design and manufacturing.For more information about [Company Name]'s Flex PCB and their comprehensive range of electronic solutions, please visit their official website at [insert website address].About [Company Name]:[Company Name] is a leading manufacturer in the electronics industry, specializing in providing innovative solutions to a wide range of electronic applications. With a strong focus on quality, reliability, and customer satisfaction, [Company Name] has established itself as a trusted partner for numerous renowned brands around the world. Their commitment to technological advancements and continuous improvement makes them a preferred choice for those seeking cutting-edge electronic solutions.###Note: The news content provided does not contain specific information about any particular brand for the Flex Printed Circuit Board.

Quality Thick Gold PCB Manufacturing: A Complete Guide

Thick Gold PCB (Printed Circuit Board) has emerged as a key player in the electronics industry, offering high-quality and reliable PCB solutions for a wide range of applications. The company has established itself as a leading provider of thick gold PCBs, catering to the needs of industries such as aerospace, automotive, medical, and telecommunications.With a strong focus on innovation and customer satisfaction, Thick Gold PCB has been able to carve a niche for itself in the highly competitive PCB market. The company’s state-of-the-art manufacturing facilities and stringent quality control measures ensure that customers receive PCBs that meet the highest standards of performance and reliability.Thick Gold PCB’s commitment to excellence is evident in its use of high-quality materials and advanced manufacturing processes. The company’s thick gold PCBs are known for their exceptional durability and resistance to wear and tear, making them ideal for use in demanding environments.In addition to its focus on product quality, Thick Gold PCB also places a strong emphasis on customer service and support. The company’s team of highly skilled and experienced engineers works closely with customers to understand their specific requirements and provide customized PCB solutions that meet their exact needs.Thick Gold PCB’s dedication to customer satisfaction has earned it a loyal and satisfied customer base, with many customers returning to the company for their PCB needs time and again. The company has built a reputation for reliability, professionalism, and integrity, and is known for delivering on its promises.Furthermore, Thick Gold PCB is committed to environmental sustainability and has implemented eco-friendly manufacturing practices to minimize its impact on the environment. The company takes pride in being a responsible corporate citizen and is constantly exploring new ways to reduce its carbon footprint and promote sustainability.Looking ahead, Thick Gold PCB is poised for continued growth and success in the PCB industry. The company is constantly investing in research and development to stay ahead of the curve and meet the evolving needs of its customers. With a strong focus on technology and innovation, Thick Gold PCB is well-positioned to maintain its leadership position in the market.In conclusion, Thick Gold PCB has established itself as a trusted provider of thick gold PCB solutions, offering high-quality products, exceptional customer service, and a commitment to sustainability. With its strong track record of success and dedication to excellence, the company is set to continue making a significant impact in the electronics industry.

The Importance of Circuit Board Assembly in Electronics Manufacturing

Circuit Board Assembly (CBA) is a critical process in the electronics manufacturing industry. It involves the process of assembling various electronic components on a printed circuit board (PCB) to create a functional electronic device. CBA is a complex and precise process that requires advanced technology and skilled labor to ensure the highest quality and reliability of the final product.One company that excels in circuit board assembly is a leading provider of electronic manufacturing services. With state-of-the-art facilities and a team of experienced engineers and technicians, they are able to offer comprehensive CBA services to a wide range of industries, including automotive, aerospace, medical, and consumer electronics.The CBA process begins with the preparation of the PCB, which involves applying a solder paste to the board. This solder paste is then used to attach electronic components such as resistors, capacitors, integrated circuits, and connectors to the board. The components are carefully placed and aligned using automated pick-and-place machines, and then heated in a reflow oven to permanently attach them to the board.The company's advanced CBA capabilities allow for high-speed, high-precision assembly of complex PCBs. They are able to handle a wide variety of component types, including surface-mount (SMT) and through-hole components, and can accommodate PCBs of various sizes and configurations. Their state-of-the-art assembly lines are equipped with advanced inspection and testing equipment to ensure the quality and reliability of every assembled board.In addition to traditional CBA processes, the company also offers advanced assembly techniques such as ball grid array (BGA) and micro BGA assembly. These techniques are used for mounting complex integrated circuits with a high pin count, and require specialized equipment and expertise to ensure proper alignment and soldering of the tiny solder balls used in these components.Furthermore, the company is committed to quality and reliability in every aspect of their CBA services. They adhere to strict quality control standards throughout the assembly process, and conduct rigorous testing and inspection procedures to ensure that every assembled board meets or exceeds the highest industry standards. This commitment to quality has earned them a reputation as a trusted partner for electronics manufacturing services, and has helped them build long-term relationships with their customers.Their dedication to excellence extends beyond the assembly process, as they also offer comprehensive design for manufacturability (DFM) and design for testability (DFT) services to help their customers optimize their PCB designs for efficient and cost-effective assembly. Their team of experienced engineers works closely with customers to identify potential issues in their PCB designs and recommend improvements to enhance manufacturability and testability.In conclusion, Circuit Board Assembly is a critical process in the electronics manufacturing industry, and the company has established itself as a leader in providing comprehensive CBA services. With advanced technology, skilled labor, and a commitment to quality and reliability, they are able to meet the needs of a wide range of industries and help their customers bring high-quality electronic products to market. Whether it is traditional CBA processes or advanced assembly techniques, the company is well-equipped to handle the most complex PCB assembly projects and deliver exceptional results.

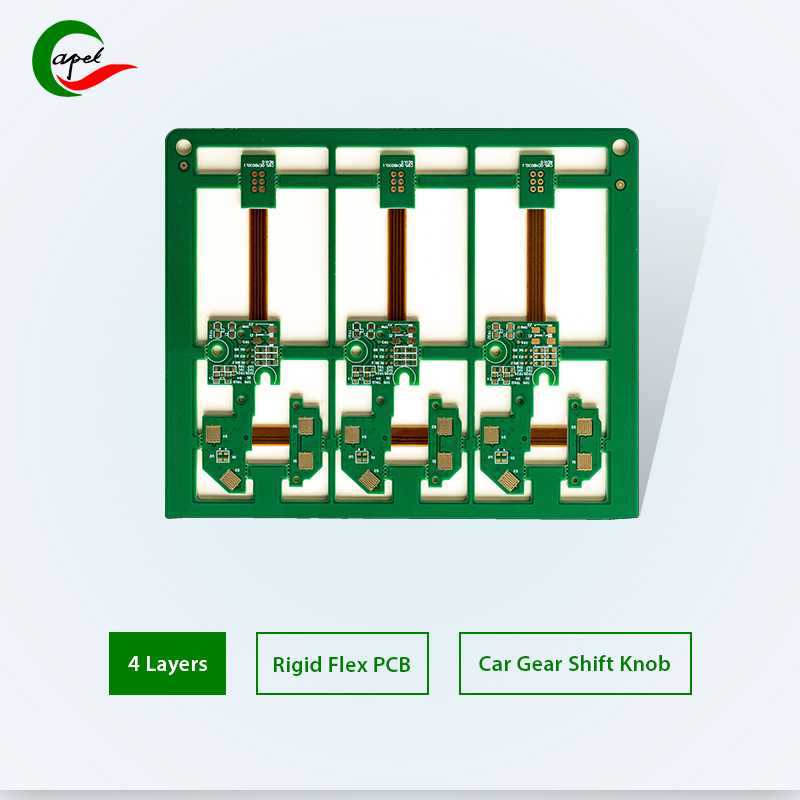

Understanding the Advantages of 4 Layer Rigid-Flex PCB Boards

4 Layer Rigid-Flex PCB Boards Revolutionize Electronic ManufacturingIn the fast-paced world of electronic manufacturing, companies are constantly seeking new ways to improve the performance and reliability of their products. One company that is leading the charge in this regard is {company name}, a leading manufacturer of high-quality printed circuit boards (PCBs). With their latest innovation - 4 layer Rigid-Flex PCB Boards - {company name} is set to revolutionize the electronic manufacturing industry.Rigid-Flex PCBs are a hybrid of traditional rigid PCBs and flexible PCBs, offering the best of both worlds. They consist of multiple layers of flexible substrate material attached to a rigid board. This unique construction allows for increased flexibility and reduced space requirements, making them ideal for applications where space is at a premium.The 4 layer Rigid-Flex PCB Boards from {company name} take this concept to the next level. By incorporating four layers of flexible substrate material, these boards offer unmatched flexibility and versatility. This allows for the creation of complex designs and intricate circuitry, while still maintaining the durability and reliability of a rigid board.One of the key advantages of 4 layer Rigid-Flex PCB Boards is their ability to reduce the overall size and weight of electronic devices. By eliminating the need for bulky connectors and cables, these boards enable manufacturers to create smaller and lighter products, without sacrificing performance or functionality.Furthermore, the unique construction of these boards also provides enhanced durability and reliability. The flexible substrate material absorbs shock and vibration, reducing the risk of component damage and failure. This makes them ideal for use in harsh environments and high-stress applications.Another major benefit of 4 layer Rigid-Flex PCB Boards is their ability to streamline the manufacturing process. By eliminating the need for multiple separate boards and connectors, these boards simplify assembly and reduce the overall cost of production. This not only saves time and money for manufacturers, but also allows for faster time-to-market for new products.{company name} has a long history of innovation and excellence in the field of PCB manufacturing. With state-of-the-art facilities and a team of skilled engineers and technicians, they have the expertise and resources to deliver the highest quality products to their customers.In addition to their cutting-edge 4 layer Rigid-Flex PCB Boards, {company name} offers a wide range of other PCB solutions, including single and double-sided PCBs, multi-layer PCBs, and flexible PCBs. They are committed to providing customized solutions to meet the unique needs of each customer, and their dedication to quality and customer satisfaction sets them apart from the competition.With the introduction of their 4 layer Rigid-Flex PCB Boards, {company name} is set to change the game in electronic manufacturing. These innovative boards offer unmatched flexibility, durability, and performance, and are poised to become the go-to solution for manufacturers looking to push the boundaries of what's possible in electronic design.As the demand for smaller, lighter, and more reliable electronic devices continues to grow, it is clear that 4 layer Rigid-Flex PCB Boards will play a vital role in shaping the future of the industry. {company name} is proud to be at the forefront of this revolution, and their commitment to excellence ensures that they will continue to lead the way in PCB innovation for years to come.

Top Flex-Rigid PCB Manufacturers: Everything You Need to Know

Flex Rigid PCB Manufacturer Sets Industry Standard for Quality and InnovationIn the competitive world of printed circuit board (PCB) manufacturing, one company stands out as a leader in quality and innovation. With a focus on flexibility and reliability, {Company Name}, a leading flex rigid PCB manufacturer, has been setting the industry standard for over a decade.Established in {Year}, {Company Name} has built a solid reputation for delivering high-quality flex rigid PCBs to its global clients. The company's state-of-the-art manufacturing facilities and advanced production techniques ensure that each PCB meets the highest industry standards for performance and reliability.{Company Name} specializes in producing flex rigid PCBs, which are essential components in a wide range of electronic devices, from smartphones and tablets to medical equipment and aerospace technology. These specialized PCBs are designed to provide both flexibility and durability, making them ideal for applications that require high-performance and reliability.One of the key differentiators for {Company Name} is its commitment to innovation. The company's dedicated research and development team is constantly exploring new materials, processes, and technologies to improve the performance and reliability of its flex rigid PCBs. This commitment to innovation has led to the development of several cutting-edge products that have set new industry benchmarks for quality and reliability.{Company Name}'s dedication to quality is evident in its rigorous quality control processes. Each PCB undergoes multiple levels of inspection and testing to ensure that it meets the company's stringent quality standards. This attention to detail has earned {Company Name} numerous certifications and accolades for its quality management system, including ISO 9001 and UL certification.The company's commitment to environmental sustainability is also evident in its manufacturing processes. {Company Name} actively implements eco-friendly practices in its production facilities, including the use of recyclable materials and energy-efficient equipment. This dedication to sustainability has earned the company recognition for its efforts to minimize its environmental impact.In addition to its focus on quality and innovation, {Company Name} prides itself on its customer-centric approach. The company works closely with its clients to understand their specific requirements and provide tailored solutions to meet their needs. Whether it's a prototype for a cutting-edge electronic device or a large-scale production run, {Company Name} has the capabilities to deliver high-quality flex rigid PCBs on time and within budget.With a solid track record of delivering superior products and exceptional customer service, {Company Name} has become a trusted partner for many leading companies in the electronics industry. The company's dedication to excellence and its commitment to innovation have positioned it as a leader in the flex rigid PCB manufacturing sector.Looking to the future, {Company Name} remains committed to pushing the boundaries of flex rigid PCB technology. The company continues to invest in research and development to develop new materials and processes that will further improve the performance and reliability of its products.As the demand for high-performance flex rigid PCBs continues to grow, {Company Name} is well-positioned to meet the needs of its clients and set new industry standards for quality and innovation. With a focus on excellence and a dedication to customer satisfaction, {Company Name} is poised to maintain its leadership in the flex rigid PCB manufacturing industry for years to come.

Ultimate Guide to 10-Layer Rigid-Flex Circuit Boards: Everything You Need to Know

As technology continues to advance, the demand for more efficient and innovative electronic products is higher than ever. One of the key components in many of these products is the circuit board, which acts as the foundation for electronic components to be mounted on. As a leading innovator in the field of electronic components, {} has recently launched a groundbreaking product in this field - the 10 layer Rigid-Flex Circuit Board.The 10 layer Rigid-Flex Circuit Board is a revolutionary product that combines the benefits of rigid and flexible circuit boards into one. This allows for a more compact and lightweight design, making it ideal for applications where space is limited. In addition, the 10 layers provide ample space for mounting a wide range of electronic components, making it a versatile solution for a variety of electronic products.One of the key advantages of the 10 layer Rigid-Flex Circuit Board is its durability and reliability. The rigid layers provide stability and support for the electronic components, while the flexible layers allow for easy bending and shaping to fit the design requirements of the product. This combination of rigidity and flexibility ensures that the circuit board can withstand the rigors of everyday use, making it a highly reliable solution for electronic products.Another key feature of the 10 layer Rigid-Flex Circuit Board is its high-density interconnect capability. This allows for a large number of interconnections to be made within a small area, reducing the overall size of the circuit board while increasing its functionality. This is particularly beneficial for applications where space is limited, such as in portable electronic devices or wearable technology.{} has a long history of innovation and expertise in the field of electronic components. The company is known for its commitment to research and development, as well as its ability to deliver cutting-edge solutions to meet the evolving needs of the industry. The launch of the 10 layer Rigid-Flex Circuit Board is a testament to {}'s dedication to pushing the boundaries of what is possible in electronic design and manufacturing.The 10 layer Rigid-Flex Circuit Board is just one example of {}'s continued efforts to provide innovative solutions for the electronic industry. With a strong focus on quality and performance, the company is well positioned to meet the demands of the rapidly evolving electronic market. By combining advanced technology with a deep understanding of customer needs, {} is able to deliver products that not only meet the requirements of today, but also anticipate the needs of the future.In summary, the launch of the 10 layer Rigid-Flex Circuit Board by {} represents a significant milestone in the field of electronic components. With its unique combination of rigidity, flexibility, and high-density interconnect capability, this product is set to revolutionize the design and manufacturing of electronic products. As {} continues to push the boundaries of what is possible in electronic design and manufacturing, it is clear that the company is committed to driving innovation and delivering high-quality solutions to meet the evolving needs of the industry.