Specification

| Category | Process Capability | Category | Process Capability |

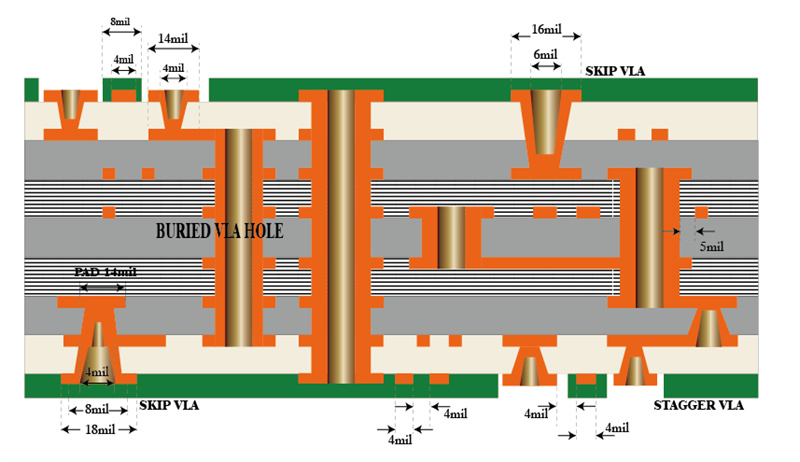

| Production Type | Single layer FPC / Double layers FPC Multi- layer FPC / Aluminum PCBs Rigid-Flex PCB | Layers Number | 1-16 layers FPC 2-16 layers Rigid-FlexPCB HDI Boards |

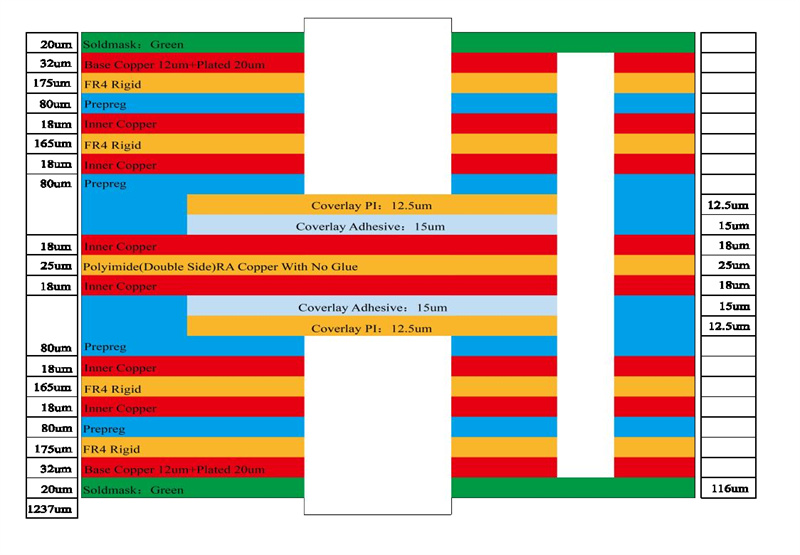

| Max Manufacture Size | Single layer FPC 4000mm Doulbe layers FPC 1200mm Multi-layers FPC 750mm Rigid-Flex PCB 750mm | Insulating Layer Thickness | 27.5um /37.5/ 50um /65/ 75um / 100um / 125um / 150um |

| Board Thickness | FPC 0.06mm - 0.4mm Rigid-Flex PCB 0.25 - 6.0mm | Tolerance of PTH Size | ±0.075mm |

| Surface Finish | Immersion Gold/Immersion Silver/Gold Plating/Tin Plat ing/OSP | Stiffener | FR4 / PI / PET / SUS / PSA/Alu |

| Semicircle Orifice Size | Min 0.4mm | Min Line Space/ width | 0.045mm/0.045mm |

| Thickness Tolerance | ±0.03mm | Impedance | 50Ω-120Ω |

| Copper Foil Thickness | 9um/12um / 18um / 35um / 70um/100um | Impedance Controlled Tolerance | ±10% |

| Tolerance of NPTH Size | ±0.05mm | The Min Flush Width | 0.80mm |

| Min Via Hole | 0.1mm | Implement Standard | GB / IPC-650 / IPC-6012 / IPC-6013II / IPC-6013III |

We do customized PCB with 15 years' experience with our professionalism

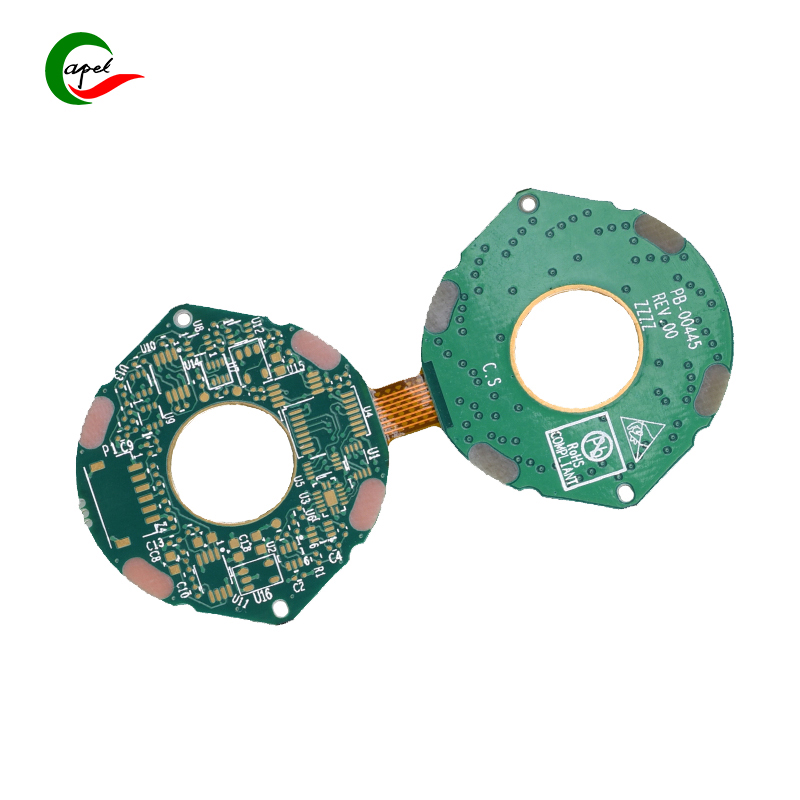

8 layer HDI PCBs

5 layer Flex-Rigid Boards

8 layer Rigid-Flex PCBs

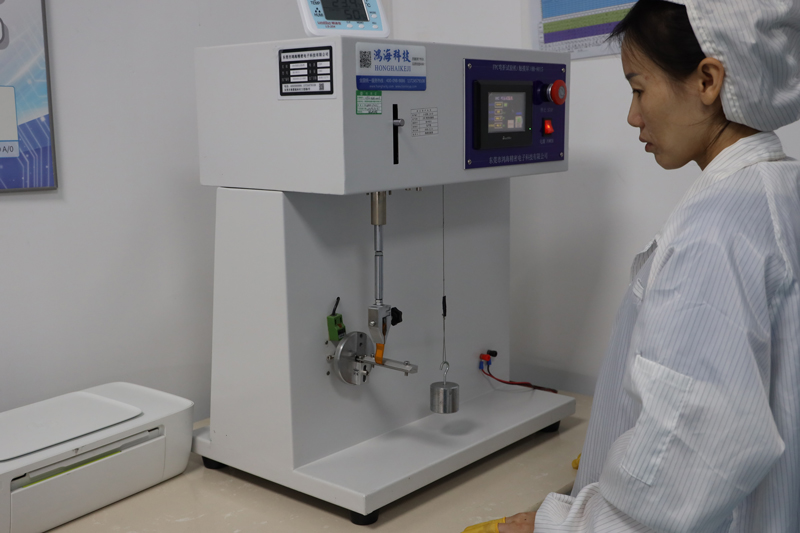

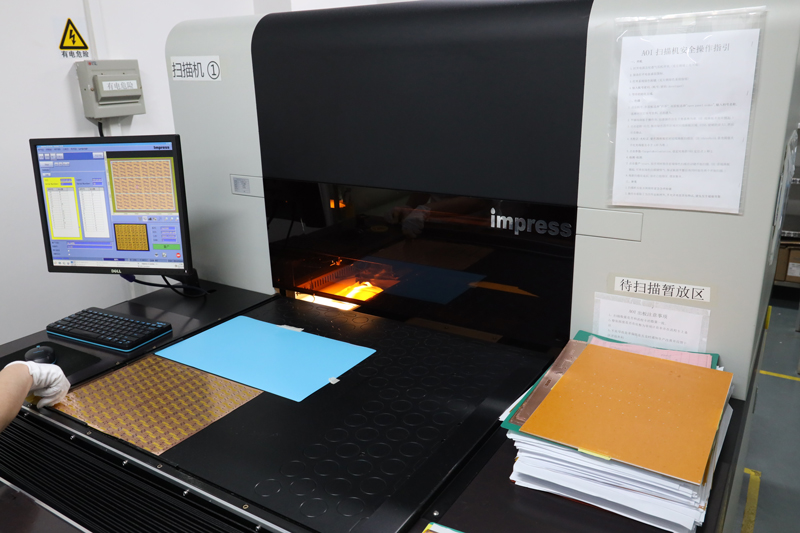

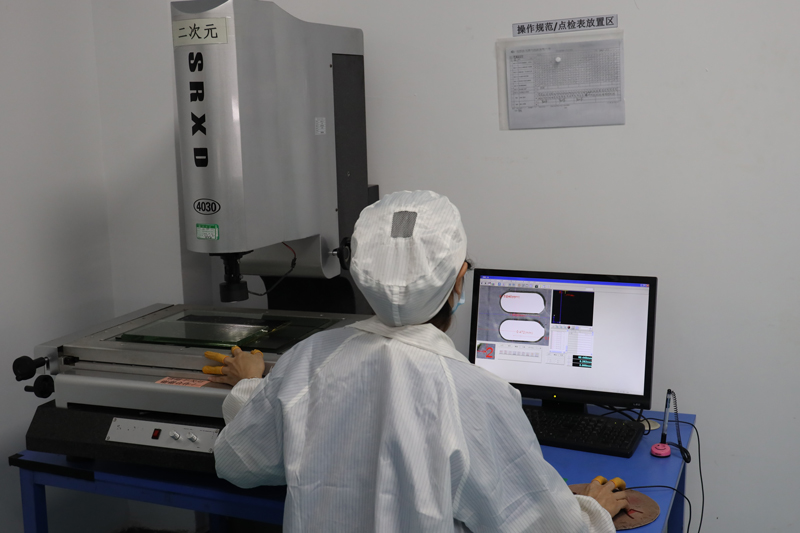

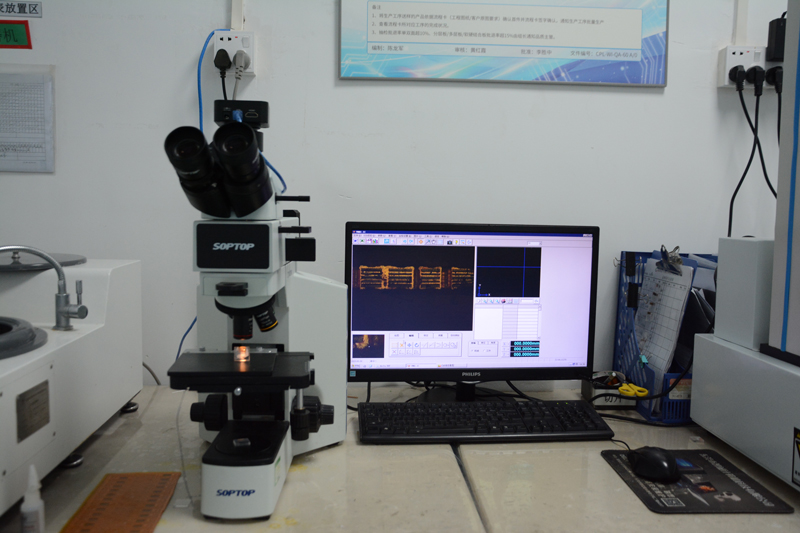

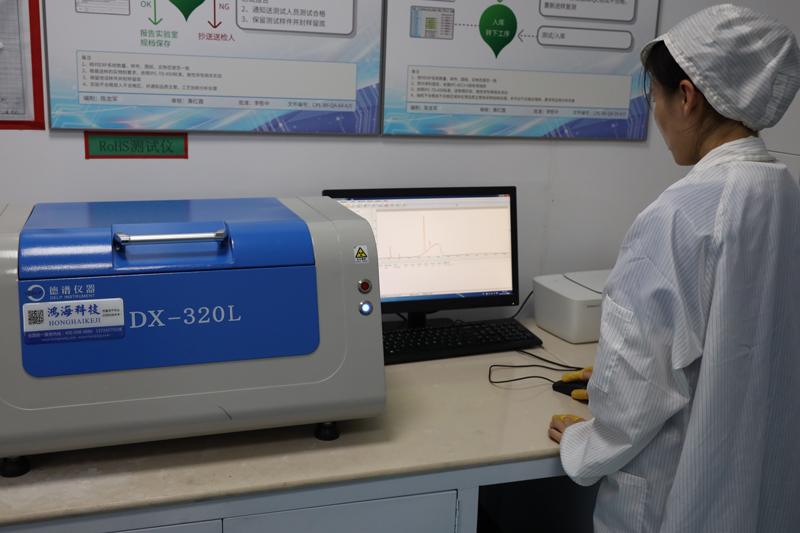

Testing and Inspection Equipment

The specific application of 12 layer Rigid-Flex PCBs in mobile phone

. Provide technical support Pre-sales and after-sales; . Custom up to 40 layers, 1-2days Quick turn reliable prototyping, Component procurement, SMT Assembly; . Caters to both Medical Device, Industrial Control, Automotive, Aviation, Consumer Electronics, IOT, UAV, Communications etc.. . Our teams of engineers and researchers are dedicated to fulfilling your requirements with precision and professionalism.

Our customized PCB Service

1. Interconnection: Rigid-flex boards are used for the interconnection of different electronic components inside mobile phones, including microprocessors, memory chips, displays, cameras and other modules. The multiple layers of the PCB allow for complex circuit designs, ensuring efficient signal transmission and reducing electromagnetic interference. 2. Form factor optimization: The flexibility and compactness of rigid-flex boards allow mobile phone manufacturers to design sleek and thin devices. The combination of rigid and flexible layers allows the PCB to bend and fold to fit into tight spaces or conform to the shape of the device, maximizing valuable internal space. 3. Durability and reliability: Mobile phones are subjected to various mechanical stresses such as bending, twisting and vibration. Rigid-flex PCBs are designed to withstand these environmental elements, ensuring long-term reliability and preventing damage to the PCB and its components. The use of high-quality materials and advanced manufacturing techniques enhance the overall durability of the device. 4. High-density wiring: The multi-layer structure of the 12-layer rigid-flex board can increase the wiring density, enabling the mobile phone to integrate more components and functions. This helps to miniaturize the device without compromising its performance and functionality. 5. Improved signal integrity: Compared with traditional rigid PCBs, rigid-flex PCBs provide better signal integrity. The flexibility of the PCB reduces signal loss and impedance mismatch, thereby increasing the performance and data transfer rate of high-speed data connections, mobile applications such as Wi-Fi, Bluetooth and NFC.

4. High-density wiring: The multi-layer structure of the 12-layer rigid-flex board can increase the wiring density, enabling the mobile phone to integrate more components and functions. This helps to miniaturize the device without compromising its performance and functionality. 5. Improved signal integrity: Compared with traditional rigid PCBs, rigid-flex PCBs provide better signal integrity. The flexibility of the PCB reduces signal loss and impedance mismatch, thereby increasing the performance and data transfer rate of high-speed data connections, mobile applications such as Wi-Fi, Bluetooth and NFC. 12-layer rigid-flex boards in mobile phones have some advantages and complementary use

1. Thermal management: Phones generate heat during operation, especially with demanding applications and processing tasks. Rigid-flex PCB's multi-layer flexible structure enables efficient heat dissipation and thermal management. This helps prevent overheating and ensures long-lasting device performance. 2. Component integration, saving space: Using 12-layer soft-rigid board, mobile phone manufacturers can integrate various electronic components and functions into one board. This integration saves space and simplifies manufacturing by eliminating the need for additional circuit boards, cables and connectors. 3. Robust and durable: 12-layer rigid-flex PCB is highly resistant to mechanical stress, shock and vibration. This makes them suitable for rugged mobile phone applications such as outdoor smartphones, military-grade equipment, and industrial handhelds that require durability and reliability in harsh environments. 4. Cost-effective: While rigid-flex PCBs may have higher initial costs than standard rigid PCBs, they can reduce overall manufacturing and assembly costs by eliminating additional interconnect components such as connectors, wires, and cables. The streamlined assembly process also reduces the chance for error and minimizes rework, resulting in cost savings. 5. Design flexibility: The flexibility of rigid-flex PCBs allows for innovative and creative smartphone designs. Manufacturers can take advantage of unique form factors by creating curved displays, foldable smartphones, or devices with unconventional shapes. This differentiates the market and enhances user experience. 6. Electromagnetic Compatibility (EMC): Compared with traditional rigid PCBs, rigid-flexible PCBs have better EMC performance. The layers and materials used are designed to help mitigate electromagnetic interference (EMI) and ensure compliance with regulatory standards. This improves signal quality, reduces noise and improves overall device performance.

4. Cost-effective: While rigid-flex PCBs may have higher initial costs than standard rigid PCBs, they can reduce overall manufacturing and assembly costs by eliminating additional interconnect components such as connectors, wires, and cables. The streamlined assembly process also reduces the chance for error and minimizes rework, resulting in cost savings. 5. Design flexibility: The flexibility of rigid-flex PCBs allows for innovative and creative smartphone designs. Manufacturers can take advantage of unique form factors by creating curved displays, foldable smartphones, or devices with unconventional shapes. This differentiates the market and enhances user experience. 6. Electromagnetic Compatibility (EMC): Compared with traditional rigid PCBs, rigid-flexible PCBs have better EMC performance. The layers and materials used are designed to help mitigate electromagnetic interference (EMI) and ensure compliance with regulatory standards. This improves signal quality, reduces noise and improves overall device performance.