Specification

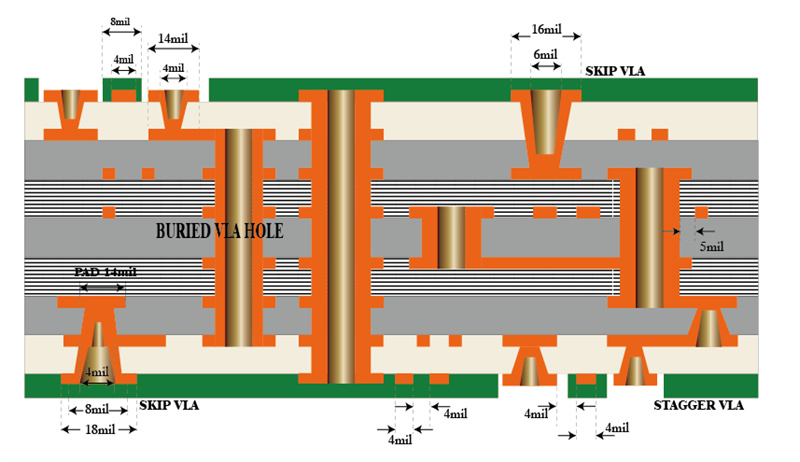

| Category | Process Capability | Category | Process Capability |

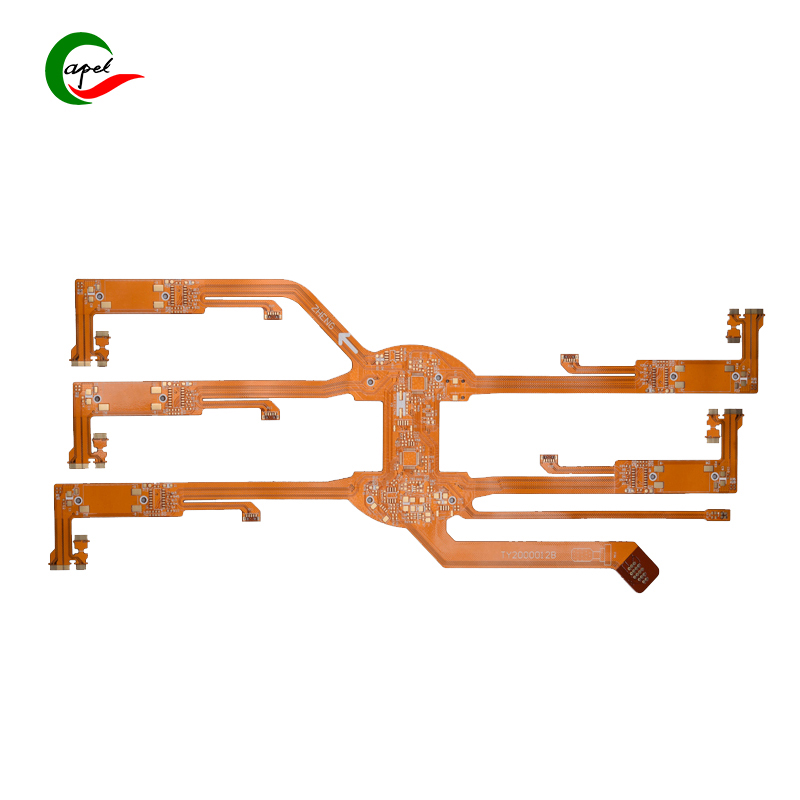

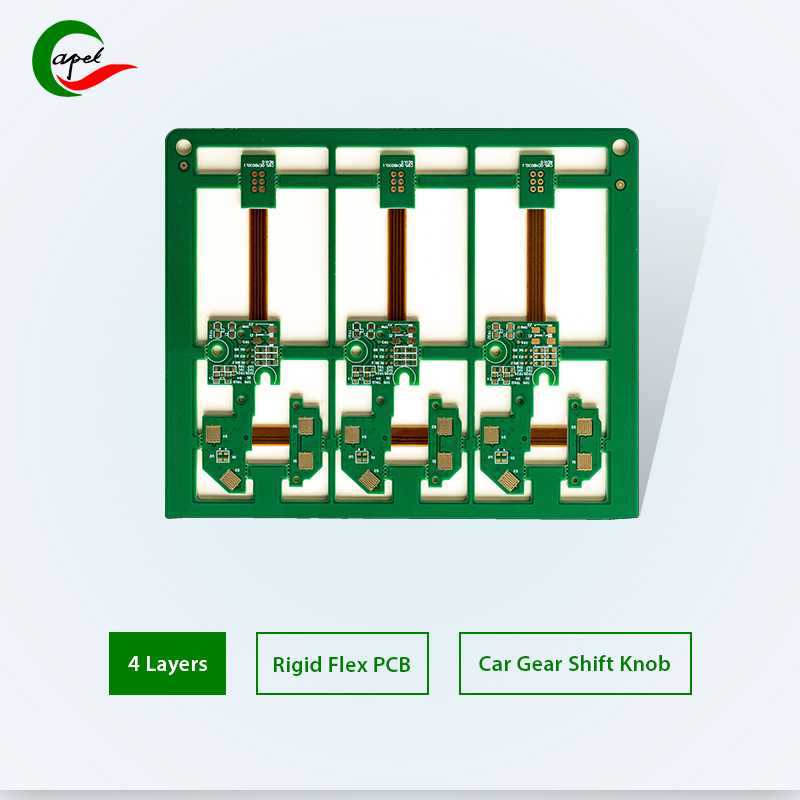

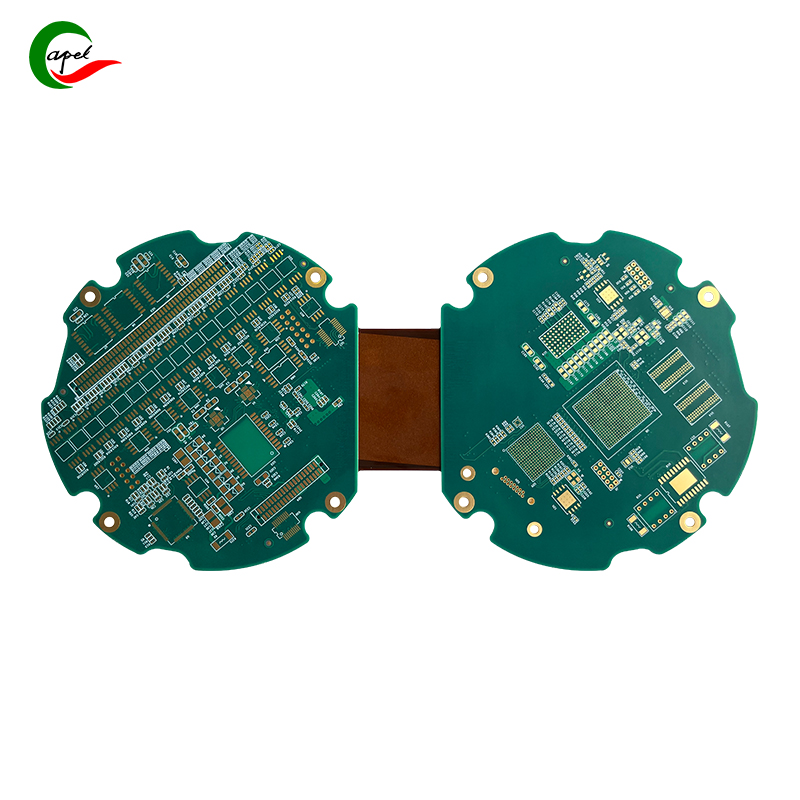

| Production Type | Single layer FPC / Double layers FPC Multi- layer FPC / Aluminum PCBs Rigid-Flex PCBs | Layers Number | 1-16 layers FPC 2-16 layers Rigid-FlexPCB HDI Printed Circuit Boards |

| Max Manufacture Size | Single layer FPC 4000mm Doulbe layers FPC 1200mm Multi-layers FPC 750mm Rigid-Flex PCB 750mm | Insulating Layer Thickness | 27.5um /37.5/ 50um /65/ 75um / 100um / 125um / 150um |

| Board Thickness | FPC 0.06mm - 0.4mm Rigid-Flex PCB 0.25 - 6.0mm | Tolerance of PTH Size | ±0.075mm |

| Surface Finish | Immersion Gold/Immersion Silver/Gold Plating/Tin Plat ing/OSP | Stiffener | FR4 / PI / PET / SUS / PSA/Alu |

| Semicircle Orifice Size | Min 0.4mm | Min Line Space/ width | 0.045mm/0.045mm |

| Thickness Tolerance | ±0.03mm | Impedance | 50Ω-120Ω |

| Copper Foil Thickness | 9um/12um / 18um / 35um / 70um/100um | Impedance Controlled Tolerance | ±10% |

| Tolerance of NPTH Size | ±0.05mm | The Min Flush Width | 0.80mm |

| Min Via Hole | 0.1mm | Implement Standard | GB / IPC-650 / IPC-6012 / IPC-6013II / IPC-6013III |

We do multi-layer flexible boards with 15 years' experience with our professionalism

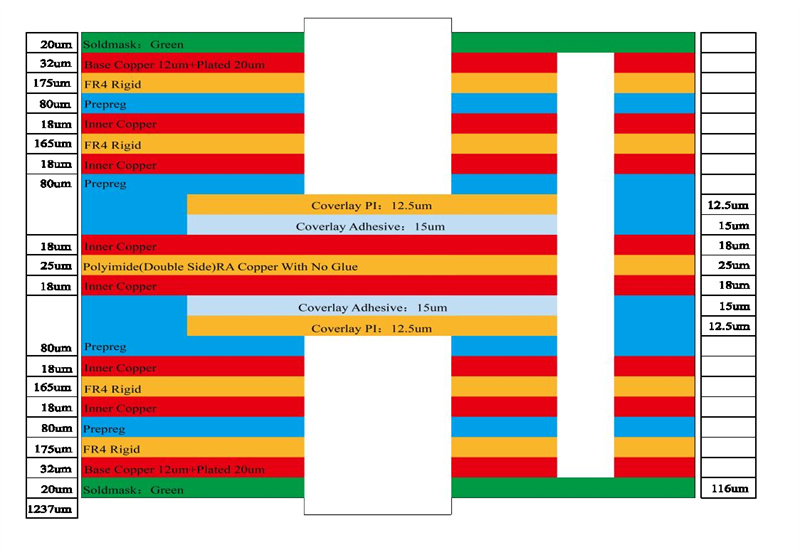

8 layer HDI Printed Circuit Boards

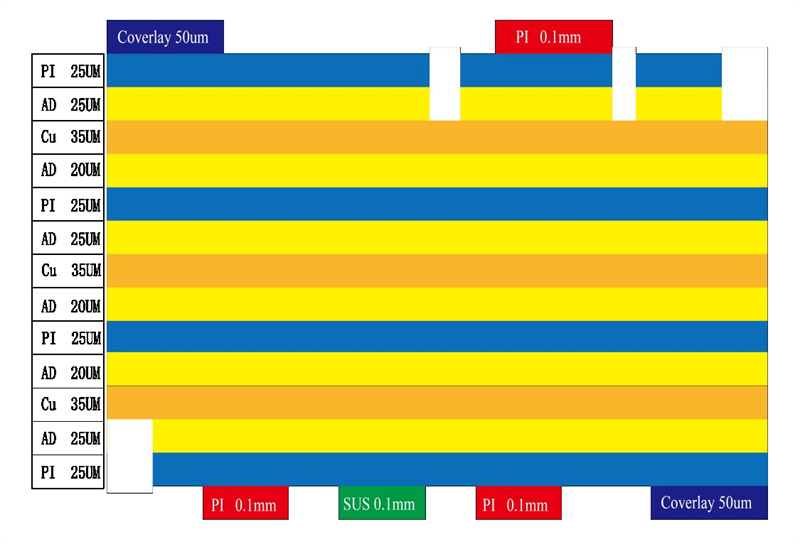

3 layer Flex PCBs

8 layer Rigid-Flex PCBs

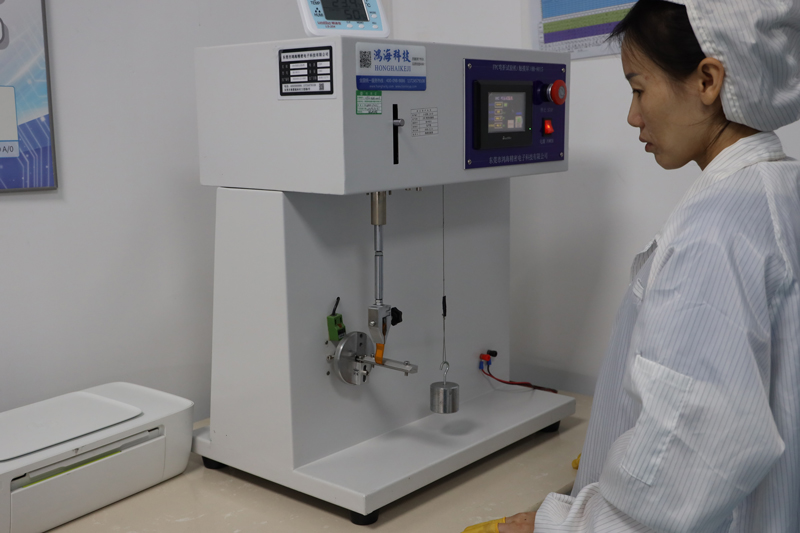

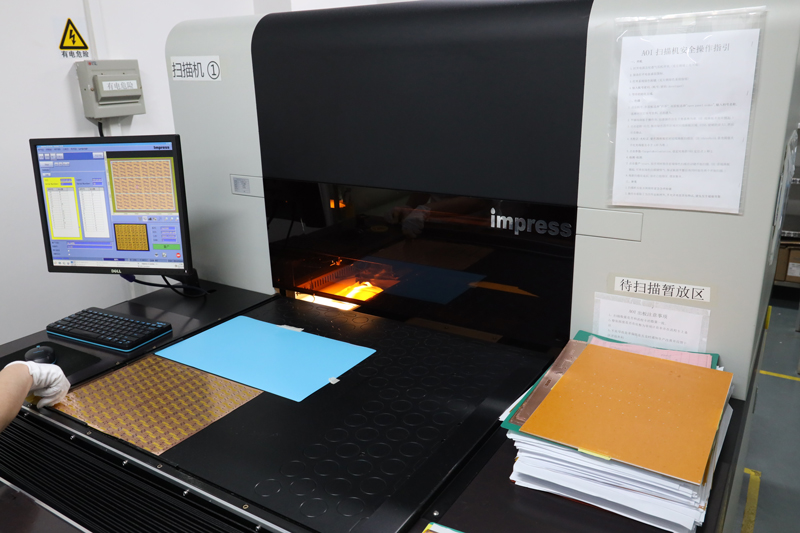

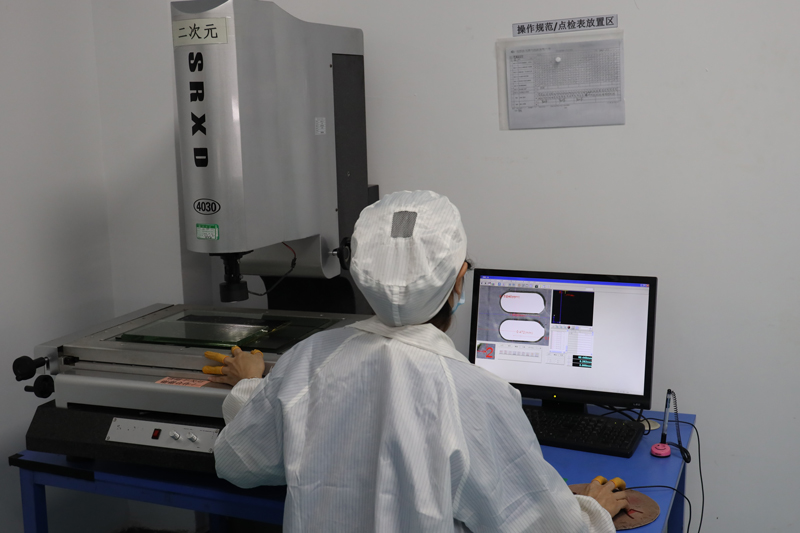

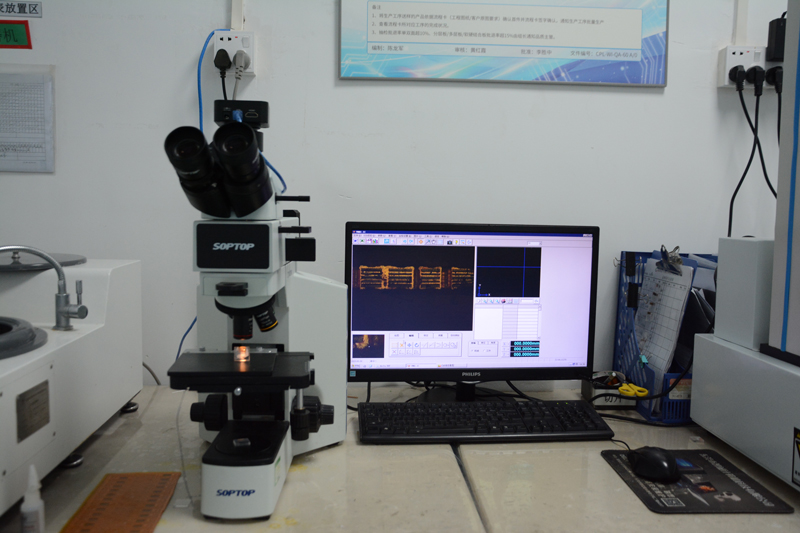

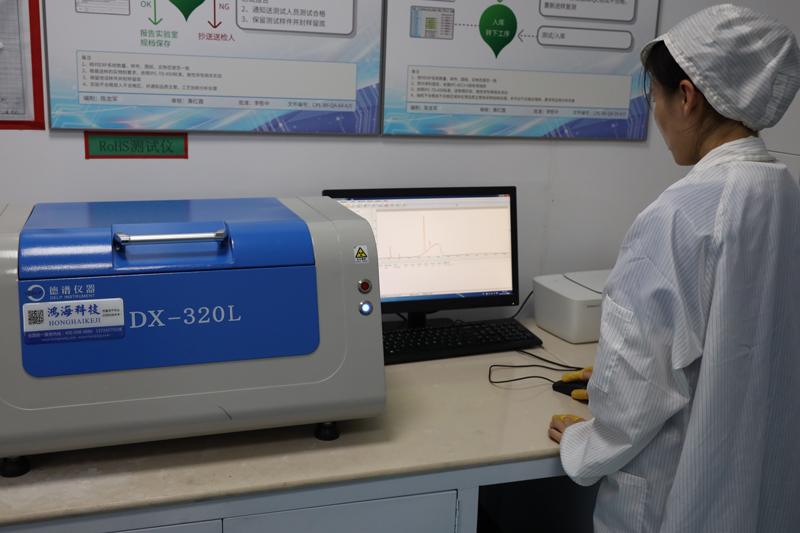

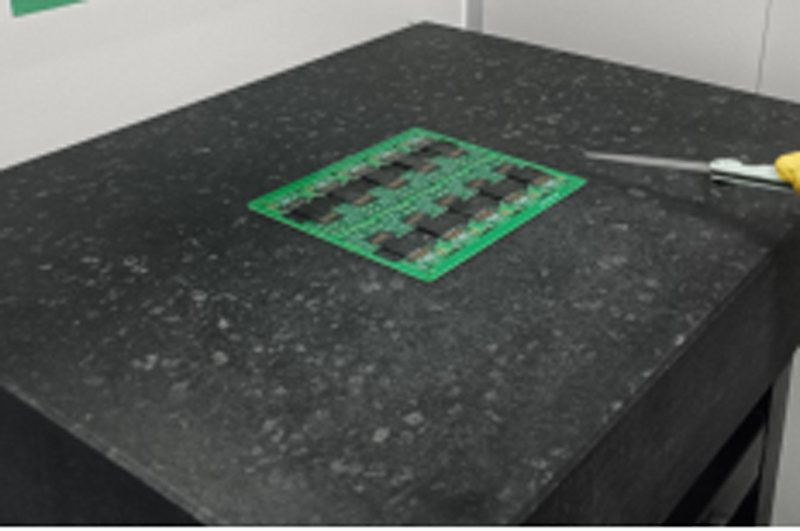

Testing and Inspection Equipment

What advanced technologies does the Double Layer Flexible PCB provide for industrial control?

. Provide technical support Pre-sales and after-sales; . Custom up to 40 layers, 1-2days Quick turn reliable prototyping, Component procurement, SMT Assembly; . Caters to both Medical Device, Industrial Control, Automotive, Aviation, Consumer Electronics, IOT, UAV, Communications etc.. . Our teams of engineers and researchers are dedicated to fulfilling your requirements with precision and professionalism.

Our Double Layer Flexible PCBs Service

1. Miniaturization: Double-layer flex PCB allows compact design and can fit into smaller spaces, making it ideal for industrial control systems with limited space availability. 2. Flexibility: The flexibility of flexible PCBs allows them to bend and conform to various shapes and sizes, enabling them to be used in complex and irregularly shaped industrial control systems. 3. High-density interconnection: Compared with traditional rigid PCB, double-layer flexible PCB provides higher density interconnection. This allows more components to be integrated into a smaller footprint, increasing the functionality and performance of industrial control systems. 4. Reliable signal transmission: flexible PCBs have excellent signal transmission capabilities, including lower transmission loss, lower electromagnetic interference (EMI), and improved impedance control. This ensures reliable and accurate signal transmission in industrial control applications. 5. Enhanced durability: Double-layer flex PCBs are designed to withstand harsh industrial environments, including temperature changes, humidity, and vibration. They are constructed of durable materials that can withstand physical stress and provide reliable operation over extended periods of time. 6. Cost-effective manufacturing: Compared with other complex interconnection solutions, double-layer flex PCBs can usually be manufactured at a lower cost due to their simplified design and manufacturing process. This makes them a cost-effective choice for industrial control systems.

5. Enhanced durability: Double-layer flex PCBs are designed to withstand harsh industrial environments, including temperature changes, humidity, and vibration. They are constructed of durable materials that can withstand physical stress and provide reliable operation over extended periods of time. 6. Cost-effective manufacturing: Compared with other complex interconnection solutions, double-layer flex PCBs can usually be manufactured at a lower cost due to their simplified design and manufacturing process. This makes them a cost-effective choice for industrial control systems. Flex PCBs FAQ

1. What are the design considerations for flex PCBs? When designing a flex PCBs, it is important to consider factors such as bend radius, number of layers required, and any electrical constraints. It is also important to choose the right substrate and adhesive to ensure the desired flexibility and durability. 2. What are the different types of flex PCBs? There are many types of flexible PCBs that can meet different design requirements, including: - Single-sided flex PCBs: Conductive traces on one side and substrate on the other. - Double-sided flex PCBs: There are conductive traces on both sides and a substrate in the middle. - Multilayer flex PCBs: has multiple layers of conductive traces and an insulating substrate. - Rigid-flex PCBs: Features a combination of rigid and flexible substrates to provide durability and flexibility. 3. What is the test procedure for flex PCBs? Flex PCBs undergo various tests throughout the manufacturing process, including electrical continuity testing, thermal testing, and mechanical testing to ensure they meet the required standards and specifications. 4. Can Flex PCBs be repaired? Flex PCBs can be repaired in some cases, but this depends on the extent of the damage. Minor damage to conductive traces or substrates can be repaired, but major damage may require replacement. 5.What factors should be considered when choosing a flex PCBs manufacturer? When selecting a flex PCBs manufacturer, it is important to consider the manufacturer's experience, expertise and reputation. You should also evaluate their production facilities, equipment, quality control procedures, and customer support services. Also, it's important to make sure the manufacturer can meet your specific design requirements and delivery schedules.

3. What is the test procedure for flex PCBs? Flex PCBs undergo various tests throughout the manufacturing process, including electrical continuity testing, thermal testing, and mechanical testing to ensure they meet the required standards and specifications. 4. Can Flex PCBs be repaired? Flex PCBs can be repaired in some cases, but this depends on the extent of the damage. Minor damage to conductive traces or substrates can be repaired, but major damage may require replacement. 5.What factors should be considered when choosing a flex PCBs manufacturer? When selecting a flex PCBs manufacturer, it is important to consider the manufacturer's experience, expertise and reputation. You should also evaluate their production facilities, equipment, quality control procedures, and customer support services. Also, it's important to make sure the manufacturer can meet your specific design requirements and delivery schedules.