Capel Flexible PCB & Rigid-Flex PCB Process Capability

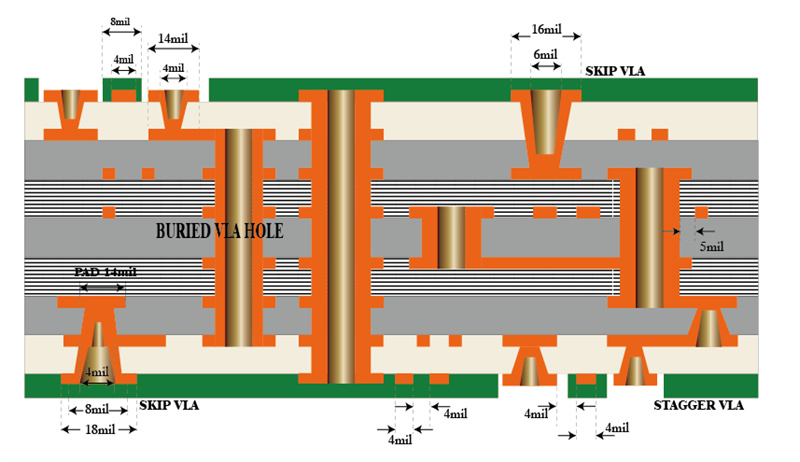

| Category | Process Capability | Category | Process Capability |

| Production Type | Single layer FPC / Double layers FPC Multi-layer FPC / Aluminum PCBs Rigid-Flex PCB | Layers Number | 1-30 layers FPC 2-32 layers Rigid-FlexPCB 1-60 layers Rigid PCB HDI Boards |

| Max Manufacture Size | Single layer FPC 4000mm Double layers FPC 1200mm Multi-layers FPC 750mm Rigid-Flex PCB 750mm | Insulating Layer Thickness | 27.5um /37.5/ 50um /65/ 75um / 100um / 125um / 150um |

| Board Thickness | FPC 0.06mm - 0.4mm Rigid-Flex PCB 0.25 - 6.0mm | Tolerance of PTH Size | ±0.075mm |

| Surface Finish | Immersion Gold/Immersion Silver/Gold Plating/Tin Plating/OSP | Stiffener | FR4 / PI / PET / SUS / PSA/Alu |

| Semicircle Orifice Size | Min 0.4mm | Min Line Space/ width | 0.045mm/0.045mm |

| Thickness Tolerance | ±0.03mm | Impedance | 50Ω-120Ω |

| Copper Foil Thickness | 9um/12um / 18um / 35um / 70um/100um | Impedance Controlled Tolerance | ±10% |

| Tolerance of NPTH Size | ±0.05mm | The Min Flush Width | 0.80mm |

| Min Via Hole | 0.1mm | Implement Standard | GB / IPC-650 / IPC-6012 / IPC-6013II / IPC-6013III |

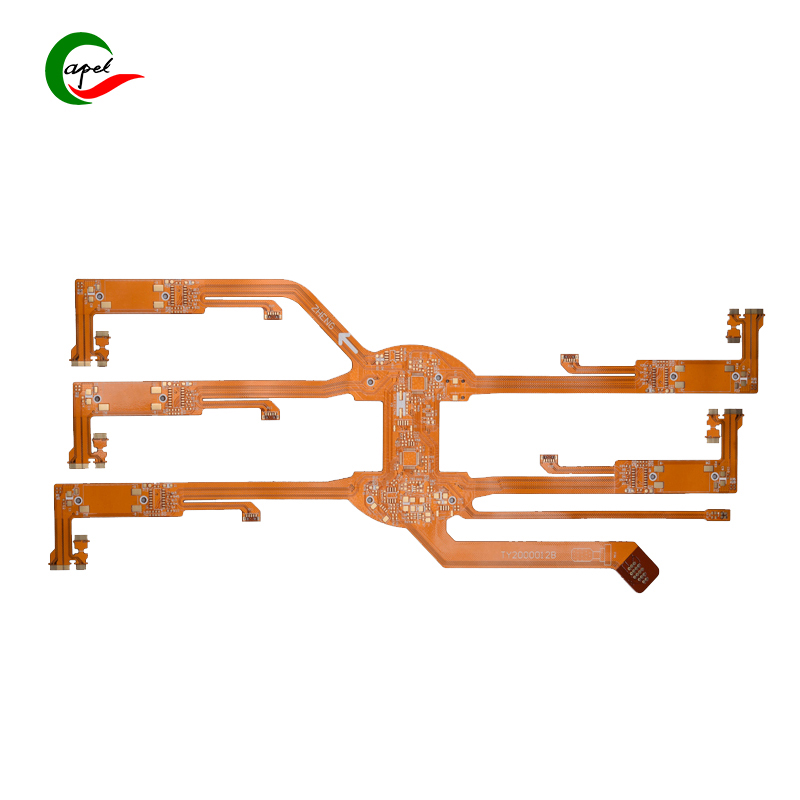

Capel do customize Flexible Circuit Board with 15 years of experience with our professionalism

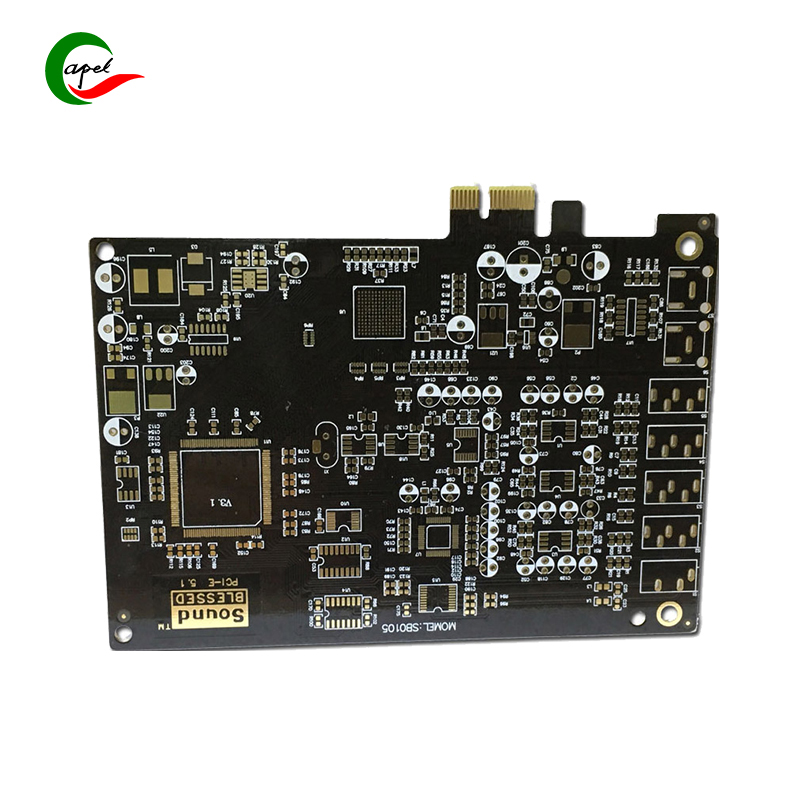

8 layer HDI PCBs

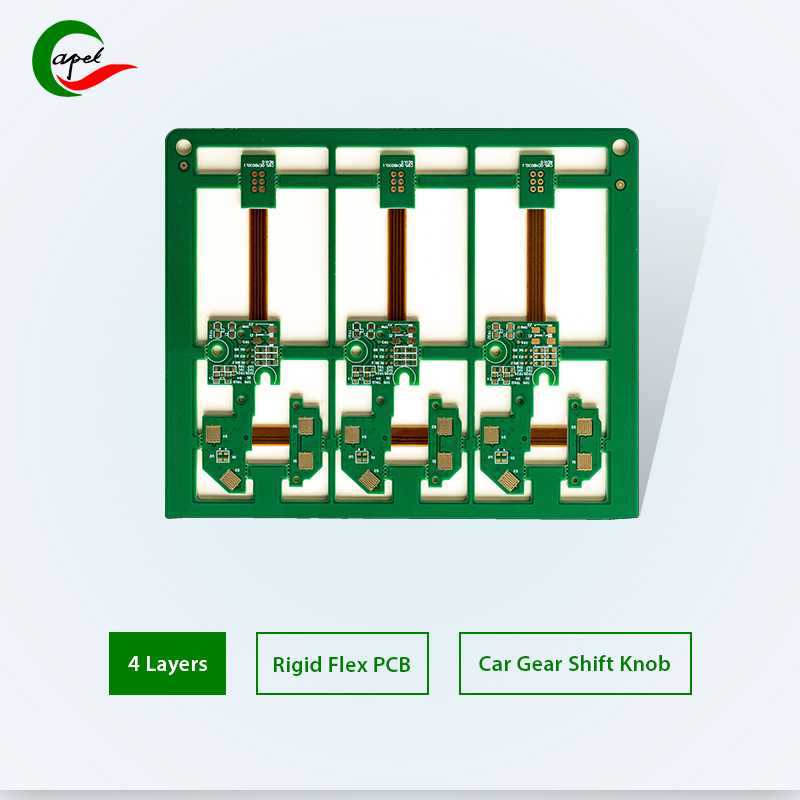

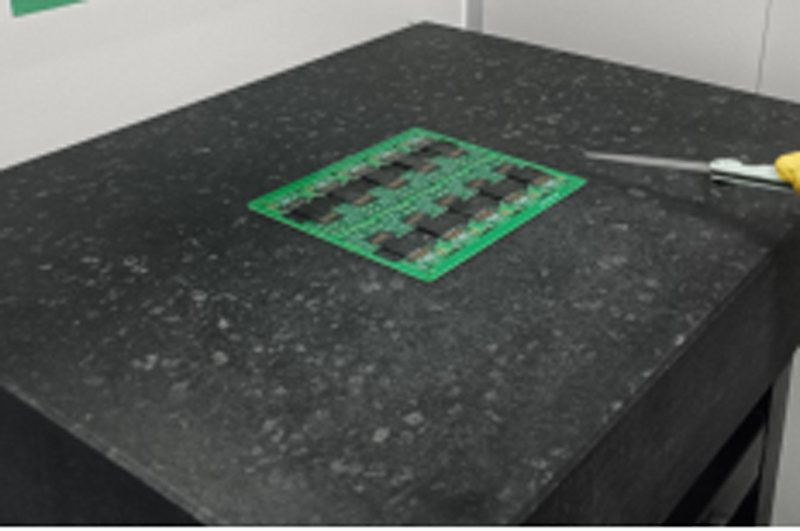

4 Layer Rigid Flex Pcb Stack Up

4-layers Rigid-Flex PCB

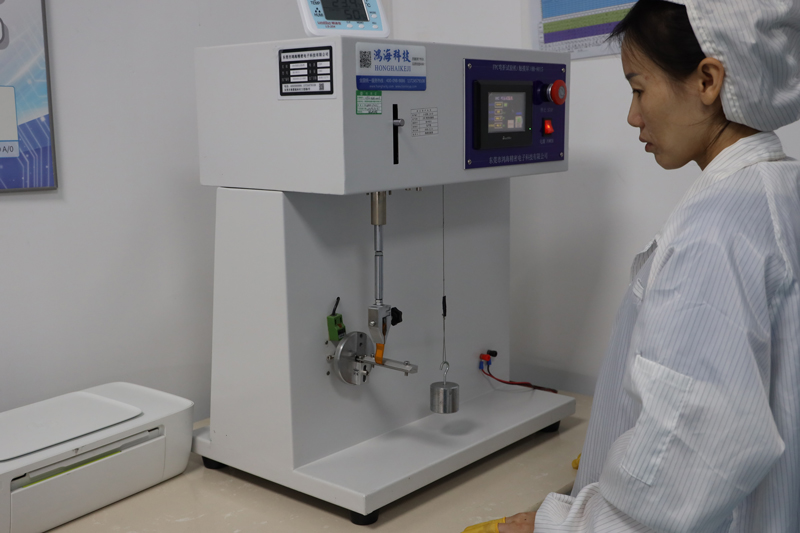

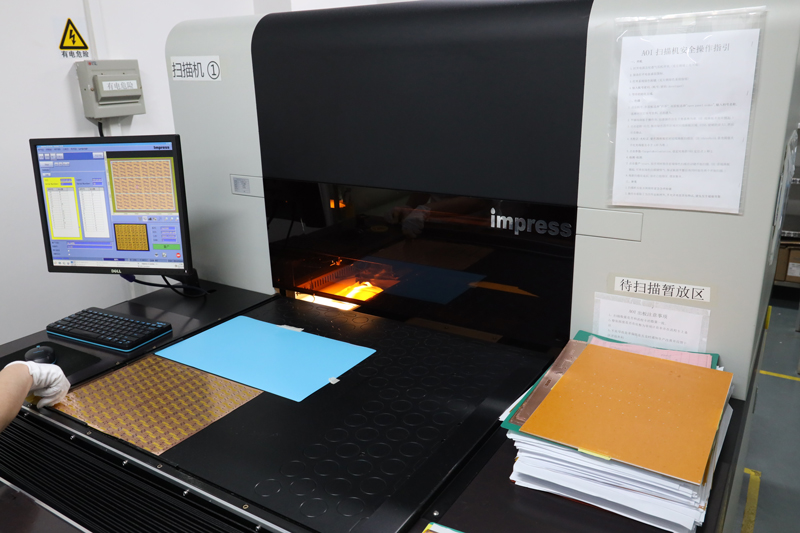

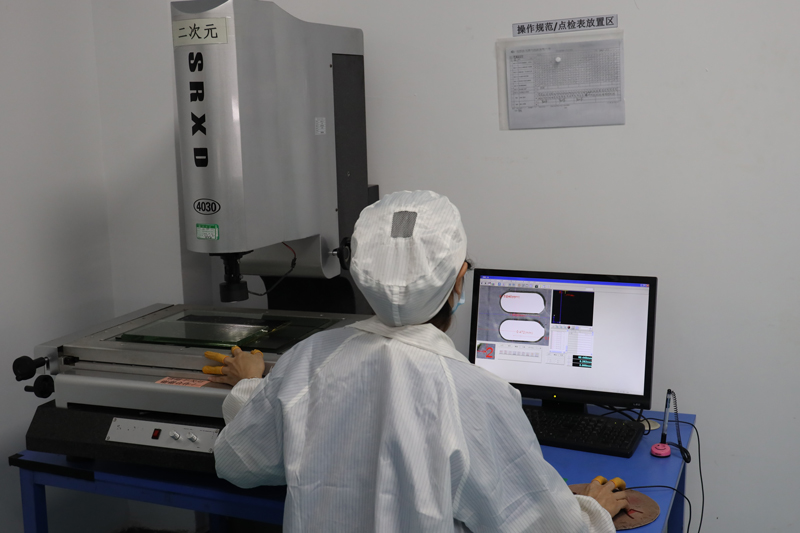

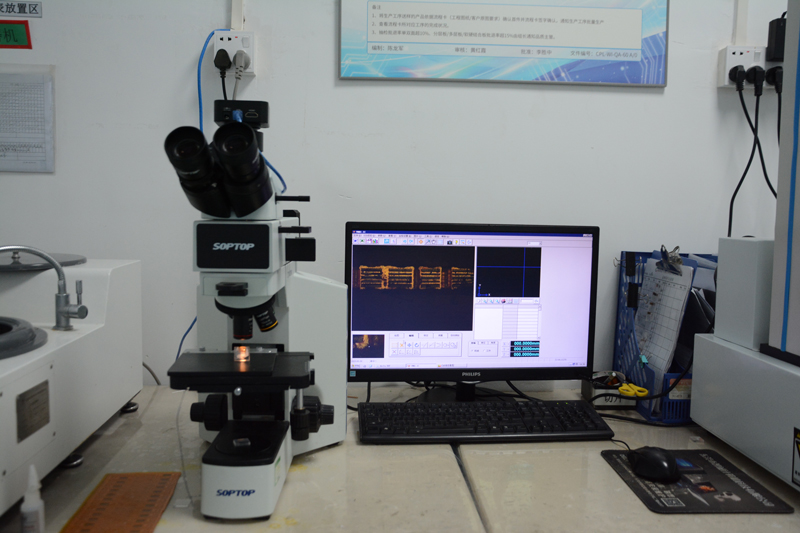

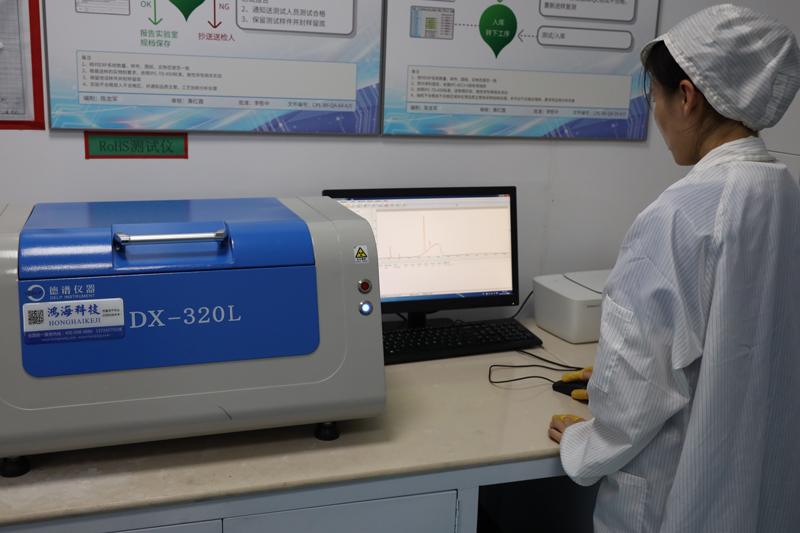

Testing and Inspection Equipment

How Capel's Multilayer Circuit Board Provides Reliability Solutions for Car Gear Shift Knob Automakers

4 Layer Rigid Flex Pcb applicated in Toyota Car Gear Shift Knob -Capel with 15 years of professional technical experience-- Owning 3 factories for Flexible PCB&Rigid-Flex PCB, Rigid PCB, DIP/SMT Assembly;

- 300+Engineers Provide technical support for Pre-sales and after-sales online;

- 1-30 layers FPC, 2-32 layers Rigid-FlexPCB, 1-60 layers Rigid PCB

- HDI Boards, Flexible PCB (FPC), Rigid-Flex PCBs, Multilayer PCBs, Single-sided PCB, Double-Sided Circuit Boards, Hollow Boards, Rogers PCB, rf PCB, Metal Core PCB, Special Process Boards, Ceramic PCB, Aluminum PCB, SMT & PTH Assembly, PCB Prototype Service.

- Provide 24-hour PCB Prototyping service,Small Batches of circuit boards will be delivered in 5-7 days, Mass Production of PCB boards will be delivered in 2-3 weeks;

- Industries we service: Medical Devices, IOT, TUT, UAV, Aviation, Automotive, Telecommunications, Consumer Electronics, Military, Aerospace, Industrial Control, Artificial Intelligence, EV, etc…

- Our Production Capacity: FPC and Rigid-Flex PCBs production capacity can reach more than 150000sqm per month, PCB production capacity can reach 80000sqm per month, PCB Assembling capacity at 150,000,000 components per month.

- Our teams of engineers and researchers are dedicated to fulfilling your requirements with precision and professionalism.

Capel customized PCB Service with 15 years of experience

Capel's 4-Layer Rigid-Flex PCB: Shaping the Future of Toyota Car Shift Knobs with Tight Tolerances and High Precision In today's automotive industry, precision and reliability are paramount. Every component used in a vehicle must meet tight tolerances and deliver high precision to ensure a smooth and safe driving experience. This is especially true for the shift knob, one of the most commonly used controls in a car. Capel, a leading printed circuit board (PCB) manufacturer, has developed a breakthrough solution to meet these demanding requirements - Capel's 4-layer rigid-flex PCB. Capel's 4-layer rigid-flex PCB, designed specifically for use in Toyota vehicles, sets a new standard in shift knob technology. But what exactly sets this PCB apart from the competition? Let's take a deeper look at its features and specifications. First, Capel's 4-layer rigid-flex PCB has tight tolerance requirements. A tolerance of 0.075mm ensures precise and accurate performance even under extreme conditions. This level of precision enhances the overall driving experience, enabling seamless gear changes and reducing the risk of any mechanical failure.In addition, the line width and line spacing precision of this rigid-flex board are very high, only 0.15mm and 0.1mm respectively. This meticulous attention to detail ensures smooth signal transmission and eliminates any chance of signal interference or loss. This precise signal transmission is crucial to the perfect functioning of the shift knob, ensuring precise shifts every time. In addition to these tight tolerance requirements, Capel's 4-layer rigid-flex PCBs are made with the highest quality materials and manufacturing processes. The board thickness of the PCB is made of a 0.15 mm flexible printed circuit (FPC) layer and a 1.6 mm rigid layer for flexibility and durability. This unique combination of flexibility and rigidity ensures that the shift knob is durable and reliable enough to withstand the wear and tear of everyday use. 1oz copper thickness and 27.5um film thickness further enhance the durability and conductivity of the PCB. With these specifications, Capel's 4-layer rigid-flex PCB guarantees a stable, efficient electrical connection for accurate, instantaneous shifting. For an added layer of protection, the rigid-flex board is finished with ENIG 2-3uin, ensuring excellent corrosion resistance and preventing any potential damage from external elements. This finish not only prolongs the life of the shift knob but also maintains its electrical performance throughout use. Capel's 4-layer rigid-flex PCBs undergo extensive functional testing including AOI (Automated Optical Inspection), 4-wire testing, continuity testing, and copper strip analysis. These test methods guarantee the reliability and trouble-free performance of each component of the PCB, leaving no room for error or failure. With exceptional functionality, Capel's 4-layer rigid-flex PCB is a perfect match for Toyota vehicles. Toyota is known for its commitment to quality and innovation, and this rigid-flex PCB lives up to its name. By incorporating this cutting-edge technology into its shift knobs, Toyota can offer customers an unrivaled driving experience that combines smooth shifting with utmost control and precision. The application of Capel's 4-layer rigid-flex PCB in a Toyota car's shift knob demonstrates the capabilities of modern technology. By combining tight tolerances and high precision, Capel revolutionized the automotive industry, setting new standards for shift knob performance and reliability. In summary, Capel's 4-layer rigid-flex PCB is a game changer for automotive shift knob technology. Its tight tolerances and high precision make it perfect for Toyota vehicles. With its exceptional durability, reliability, and performance, this rigid-flex PCB ensures smooth and precise gear shifting, providing the driver with an unrivaled driving experience. Capel continues to push the boundaries of PCB technology, shaping the future of automotive engineering one component at a time.